As one of the representative steel grades of the Cr-Ni-Mo series in the American Standard, 4340 steel is a typical medium carbon low alloy structural steel which is considered to be one of the most popular steel grades in the South American market.

4340 steel is known for its high toughness and high strength, usually referring to its heat-treated condition.After quenching and tempering heat treatment,4340 steel has high strength and toughness, as well as excellent hardenability, good wear resistance and fatigue resistance.

Due to its excellent performance characteristics,as widely used as 4140 steel, 4130 steel, 4145H steel,4340 steel is also one of the most popular petroleum steel grades in the oil and gas industry.

4340 steel is used in the manufacture of important parts of large size that require good toughness and high strength,such as heavy machinery and high-load shafts (Helicopter rotor shaft, turbine shaft),gears, fasteners, etc.

4340 STEEL CHEMICAL COMPOSITION

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

ASTM A29 | 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | ≤0.035 | ≤0.04 | 0.7-0.9 | 0.2-0.3 | 1.65-2.00 |

| E4340 | 0.38-0.43 | 0.15-0.35 | 0.65-0.85 | ≤0.025 | ≤0.025 | 0.7-0.9 | 0.2-0.3 | 1.65-2.00 |

4340 STEEL BRIGHT BAR PRODUCTION PROCRSS

- 4340 Steel Heat Treatment Production Line

Automatic intermediate frequency quenching production line

Box type trolley furnaces

High frequency induction hardening production lines

- Equipped with Automated Medium/High frequency induction hardening production lines

- Equipped with Box type trolley furnaces

- Equipped with Straightening machine

- Heat treatment diameter:Dia 14-1000mm

- Length limit: below 13,000mm

- 4340 Steel Machining Service

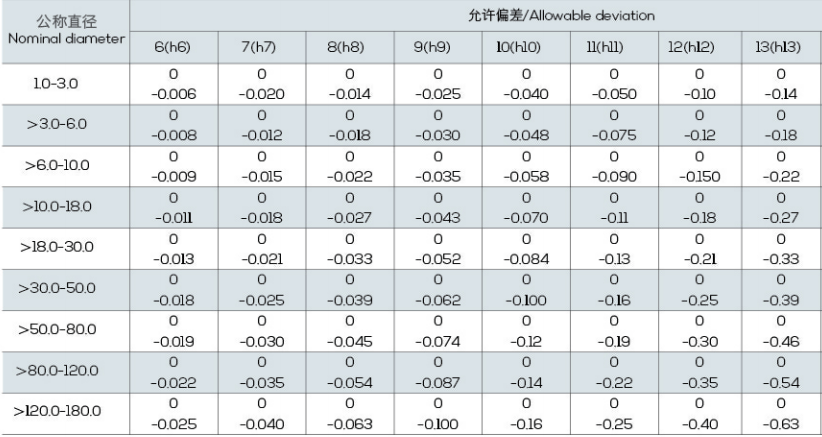

4340 Bright Bar Allowable Diameter Tolerance

4340 Bright Bar Straightness & Surface Roughness

| Category | Code | Straightness ,mm/m | Roughness,Ra/μm |

| Peeling Material | SF | ≤1 | ≤3.0 |

| Polished Material | SP | ≤2 | ≤5.0 |

| Polishing Material | SB | ≤1 | ≤0.6 |

- 4340 Steel Cutting Service

Cut -Off Standard For 4340 Steel

Length Management:Fully automatic import cutting equipment is adopted to ensure tolerance and verticality.

Weight Management:Weighing according to customer requirements, and unified management according to requirements.

- Cutting Tolerance:+/-0.05-0.07mm

- Vertical Tolerance:+/-0.05-0.07mm

- Surface Finish Roughness:Ra≤3.2μm

- Roundness:+/-0.1 – +/-0.2mm

- Straighteness: +/-5mm( in 6m length)

- 4340 Steel Dimensional inspection

- 4340 Steel Hardness check

- 4340 Steel Mechanical property testing

4340 Steel Mechanical property

| Size(mm) | Rm(Mpa) | Rel(Mpa) | A5(%) | Z(%) | Aku(J) |

| Φ60 | 1200 | 1020 | 19 | 58 | 120 |

| Φ260 | 967 | 859 | 22.5 | 59 | 110 |

| Φ304.8 | 1075 | 985 | 18.5 | 50 | 80 |

| Φ430 | 825 | 650 | 17 | 55 | 86 |

| 300*400 | 915 | 794 | 20 | 56 | 92 |

Remark:The above data is the real test data of the laboratory, for your reference only

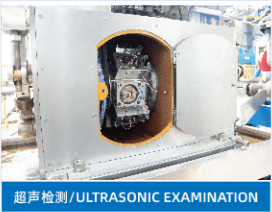

- Automatic Flaw Detection System

14-Channels Ultrasonic Testing

- Four probes in 4 Channels:Detecting longitudinal cracks inside and outside the bar in two directions

- Six probes in 6 Channels:Detecting transverse cracks inside and outside the bars

- Four probes in 4 Channels:Detecting internal defects in the bars

3-Channels Eddy Current Testing

Detection method of probe rotation,Detecting surface and near surface defects.

Detection diameter:Ф17mm~Ф80mm

Detection length:3-9m

Straightness:≤1.5mm/m

Detect applicable materials:High strength steel,Carbon tool steel,Carbon structural steel,Alloy structural steel,Tool steel,Spring steel,Bearing steel,High-speed steel,Stainless steel

Defect detection capability

The following comparative defects can be detected in the online state.

Center cross hole:Ф0.8x15mm

2mm horizontal hole under the skin:Ф0.5×12.7mm

Surface groove:depth x width x length 0.1×0.1x10mm

- 4340 Steel Packing for delivery

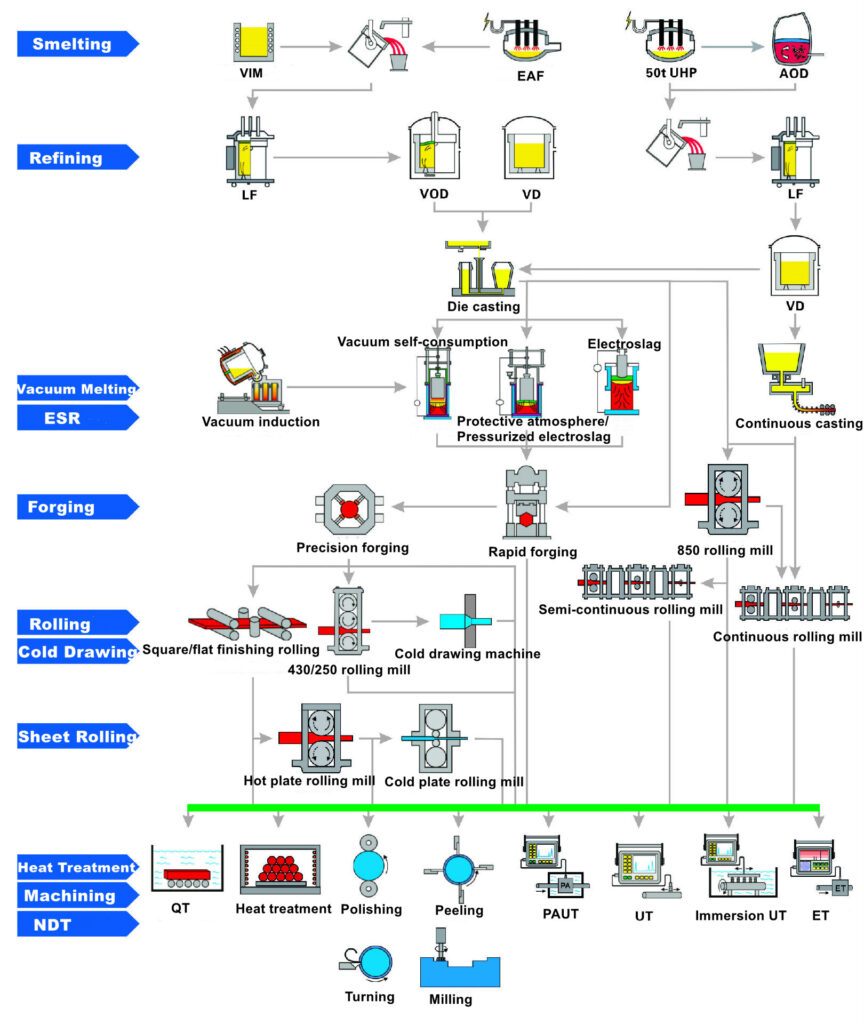

- 4340 Steel Production Process Flow Chart

BECOME YOUR STRATEGIC PARTNER IN YOUR SUPPLY CHAIN

- Strategic Partners with Halden

- What We Supply For 4340 Steel

- Dia 16-200mm daily stock wih 1000+tons round bars

- Annealed/Q&T(pre hardened)condition for 5 days delivery available

- Bright steel with QT condition for 10 days delivery available

- Cut to length service available

- Daily stock ingots to meet customer urgent order needs

- Dia 80-1000mm full size forging available

- Square/Flat/Blocks/Shafts customized production

- One-stop machining service

- Guaranteed inspection and testing