As oil & gas steel, 4130, 4140 and 4340 steel are widely used in the oil and gas industry, such as wellhead devices, Christmas tree equipment, and natural gas pipelines.

In the previous article, we introduced in detail the difference between 4140 steel and 4340 steel.Here, we will continue to compare steel types with closer properties, namely 4130 steel and 4140 steel.We hope it can help you decide which one is best for your needs. Let’s break down the similarities and differences between these two steels.

If you are interested, please refer to the article: 4140 steel vs 4340 steel

1.Steel Grade & Chemical Composition

Whether it is SAE 4140, SAE 4130, or AISI 4140, AISI 4130, they all apply to the American Standard’s unique naming system rules, which are simple and clear.Since we are talking about the difference between 4140 and 4130 here, let’s talk about this aspect first.

| 4140 | Classification rule | 41 | 40 | |||||

| Cr 0.50/0.8/0.95%, Mo 0.12/0.20/0.30% | C 0.4% average | |||||||

| Standard | Cr | Mo | C | Mn | Si | P | S | |

| 0.8-1.1 | 0.15-0.25 | 0.38-0.43 | 0.75-1.00 | 0.15-0.35 | ≤0.035 | ≤0.04 | ||

| 4130 | Classification rule | 41 | 30 | |||||

| Cr 0.50/0.8/0.95%, Mo 0.12/0.20/0.30% | C 0.3% average | |||||||

| Standard | Cr | Mo | C | Mn | Si | P | S | |

| 0.8-1.1 | 0.15-0.25 | 0.28-0.33 | 0.4-0.6 | 0.15-0.35 | ≤0.035 | ≤0.04 | ||

From the above table,we can clearly understand the naming rules of 4140 and 4130, and clearly see the inherent connection and difference between the numerical codes and chemical element compositions.

There is a significant difference in carbon content between 4140 and 4130, with an average difference of 0.1%. In addition, for the Mn element, although both are less than 1%, there is no coverage interval between them.

2.Manufacturing Cost

For 4130 steel and 4140 steel, which have basically the same alloying elements, the alloy cost is the same, so it can be said that the difference is only in the carbon content.In terms of actual manufacturing cost, 4130 steel with lower carbon content is slightly more expensive than 4140 steel, but the difference is not very big, usually within 5%.

3.Weldability

4130 and 4140 are both alloy steels, and their weldability will be affected by many factors, such as carbon content, alloying element content, heat treatment status, etc.

Considering that the alloying elements are the same, all element contents are selected as average values. So in this case, According to the carbon equivalent calculation formula CE=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 recommended by the International Institute of Welding (IIW),the CE value of 4130 is approximately 0.61,while the 4140 is about 0.78.Obviously, the weldability of 4130 steel is better than that of 4140 steel.

As for weldability, since 4130 steel has good plasticity and toughness, its weldability is better. 4140 steel has a higher carbon content, which may cause some problems during welding, such as hardenability and crack sensitivity. In the specific welding process, various factors such as welding process, welding materials, and joint design also need to be considered. It is recommended to conduct welding process qualification before performing welding operations to ensure welding quality and safety.

4.Hardenability

Hardenability refers to the minimum quenching hardness that the core and surface of steel materials can achieve during the quenching process, as well as the ability to harden the depth of the layer. Therefore, different steel materials have different hardenability, and the comparison of hardenability also requires specific analysis.

Generally speaking, the carbon content of 4130 steel is low, nominally 0.30%C, which results in its cooling speed not being fast enough during quenching, thus affecting its hardenability. It is usually water quenched to reach a maximum quenching hardness of about 48 HRC.

The hardenability of 4140 steel is relatively good. Its higher carbon content allows it to cool faster when quenched, thereby improving its hardenability. Quenching is usually performed to achieve a quench hardness of approximately 54-59 HRC, depending on the precise carbon content.

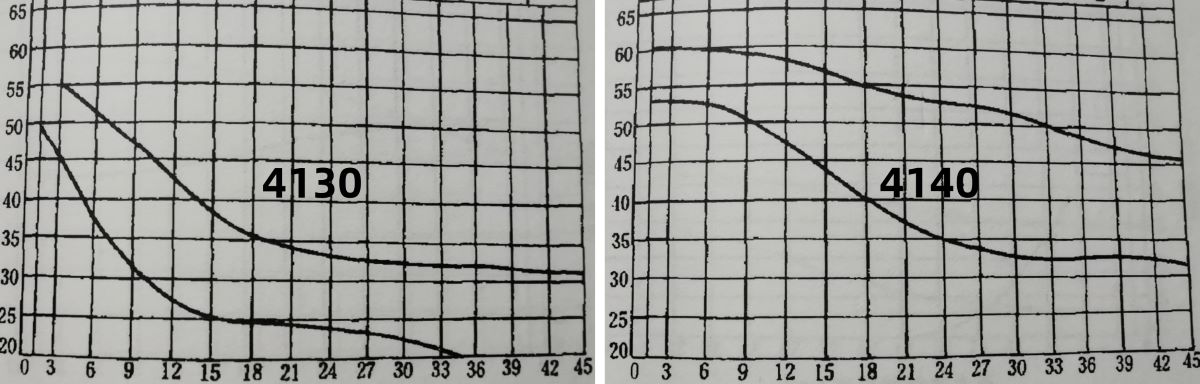

Hardenability curve comparison chart: 4130 vs 4140

Therefore, from the perspective of hardenability, 4140 steel has better hardenability than 4130 steel.

5.Machinability

4130 steel and 4140 steel are both steel types with good machining properties, but they behave differently during the machining process.

In the annealed condition, both 4130 steel and 4140 steel can be said to be easy to process due to their low hardness.However, in the quenched and tempered state, due to the higher strength and hardness of 4140 steel, it may be more difficult to machine than 4130 steel.

Compared with other materials, we believe that 4140 steel and 4130 steel are still easy to machine.

6.Mechanical Property

For 4130 steel and 4140 steel, when it comes to mechanical properties, it usually refers to the performance data in its quenched and tempered state.

| Grade | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 4130 | ≥655Mpa | ≥517Mpa | ≥17% | ≥35% | ≥27J | 197-237 HBW |

| 4140 | ≥931Mpa | ≥838Mpa | ≥16% | ≥50% | ≥54J | 268-302 HBW |

Generally speaking, the strength and hardness of 4140 steel are usually higher than those of 4130 steel. Therefore, in terms of mechanical properties, the mechanical performance data of 4140 steel is higher than that of 4130 steel.

4130 steel and 4140 steel are often used in petroleum equipment. The commonly used performance requirements of 4130 are 60K and 75K, while 4140 has a wider range, including 60K, 75K, 80K, and even 110K.Therefore, when it comes to specific applications, the choice of which steel to use needs to be comprehensively considered based on the actual application.

7.Application

As chromium-molybdenum low-alloy steels, 4140 steel and 4130 steel can obtain good mechanical properties through appropriate heat treatment, so they are widely used in various industries.

4130 steel is mainly used to manufacture quenched and tempered parts with large cross-sections and working under high stress conditions. Specific application examples are as follows:

- Aerospace field: used to manufacture aero engines, aircraft structural parts, etc.

- Petrochemical industry: used to manufacture oil and natural gas drilling equipment, pipelines, etc.

- Machinery manufacturing field: used to manufacture bearings, gears and other parts.

In addition, 4130 steel can also be used to manufacture automobile parts, cutting tools, drilling machinery, etc.

4140 steel has higher strength, hardness and toughness than 4130 steel after heat treatment. Therefore, 4140 steel has a wider range of applications than 4130 steel.The following are specific application examples of 4140 steel:

- Automobile manufacturing industry: used to manufacture key components such as crankshafts, connecting rods, and piston pins.

- Aerospace industry: used to manufacture key components such as aircraft landing gear and fuselage.

- Medical device industry: used to manufacture high-strength structural components.

- Tool manufacturing industry: Suitable for manufacturing various tools, such as drill bits, cutting tools, etc.

- Construction industry: used to manufacture structural components such as bridges and high-rise buildings.

In addition, 4140 steel, like 4130 steel, is also widely used in the oil and gas industry.

As a stockist of high-quality steel 4140 steel and 4130 steel, we are willing to provide customers with high-quality products and services. If you have this demand, please feel free to contact us.