42CrMo4/DIN 1.7225 STEEL BUYING GUIDE

When you are looking for 42CrMo4 material, what you need to know is that 42CrMo4, as a European grade, is one of the most commonly used steel grades. Faced with many 42CrMo4 steel suppliers with uneven quality levels.How to choose high-quality 42CrMo4 from them?Many people find it hard and challenging to understand, but in reality, it’s actually simple.

Through the guidance of this article, you can learn some necessary technical specifications about 42CrMo4 steel,so as to help you have the confidence and ability to choose high-quality 42CrMo4 materials.

Then, we will start to learn!

WHAT IS 42CrMo4 STEEL?

42CrMo4 Steel, refers to DIN 1.7225 steel.As one of the widely used Cr-Mo series of typical alloy steels, it has been adopted and included by major European standards, such as EN10083, EN10250 standard.

From the letters, we can guess that it contains Cr and Mo, so what do the other numbers represent? To understand this, let’s first understand the naming rules.

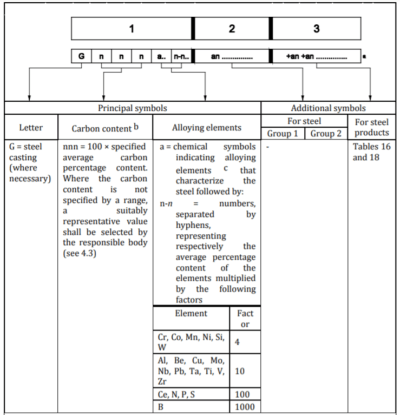

We can see the below Table 13 from EN10027 Standard:Designation systems for steels.

Key

1 = Principal symbols

2 = Additional symbols for steel

3 = Additional symbols for steel products

a n = numerical characters, a = alpha characters, an = alphanumeric characters.

b To distinguish between two similar steel grades, the number indicating carbon content may be increased by 1.

c The sequence of symbols shall be in decreasing order of the values of the average percentage content; where the values of contents are the same for two or more elements, the corresponding symbols shall be indicated in alphabetical order.

From the above information, we know that ’42’ in 42CrMo4 represents its average carbon content of 0.42%.This is the same as the last two ’40’ in the US grade 4140, which represents 0.4% of the carbon content.The last number 4 represents the average content of Cr is 4/4=1%,the Mo content is not mentioned.

IS 42CRMO4 STEEL SAME AS EN19 STEEL?

42CrMo4 is European grade mainly from EN10083 and EN10250 standard,while EN19 is British grade from BS970-1955 standard.Although they are very close in chemical composition, they are different grades and can be considered eqnivalent grades.Through technical adjustments, we can adjust their components to the corresponding effective range in the table below, so that they can be used instead.

| 42CrMo4 | EN19 | Adjustment for EN19 and 42CrMo4 |

| C:0.38-0.45% | C:0.35-0.45% | C:0.38-0.45% |

| Si:≤ 0.4% | Si:0.10-0.35% | Si:0.15-0.35% |

| Mn:0.6-0.9% | Mn:0.5-0.8% | Mn:0.6-0.8% |

| Cr:0.9-1.2% | Cr:0.9-1.5% | Cr:0.9-1.2% |

| Mo:0.15-0.30% | Mo:0.2-0.40% | Mo:0.2-0.3% |

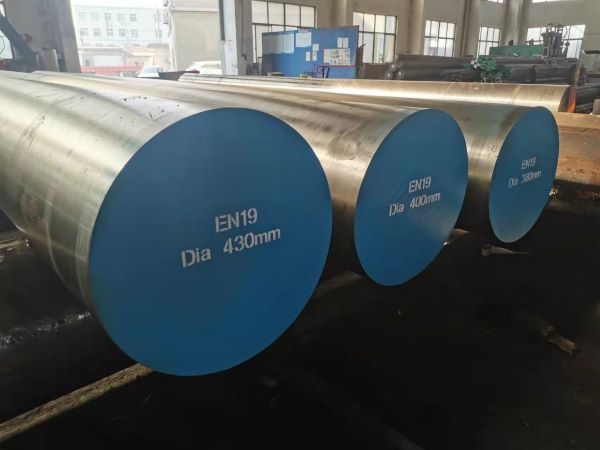

EN19 Forged round steel with Quenched and Tempered Condition

Other Equivalent Grade

China/GB 3077:42CrMoA

USA/ASTM A29:4140/4142

Japan/JIS G4105:SCM440

QUICK FAQS FOR 42CRMO4 STEEL

Is 42CrMo4 Steel Low-Carbon Alloy Steel?

From the above content,we know that 42CrMo4 has an average carbon content of 0.42%,the specific range is 0.38-0.45%.It does not belong to the low-carbon category(C≤0.25%), so 42CrMo4 steel belongs to medium-carbon low-alloy steel.

What is 42CrMoS4 Steel?

42CrMoS4, can be regarded as 42CrMo4 with sulfur control,we can see below table for 42CrMoS4 chemical elements.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 42CrMoS4/1.7227 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | ≤ 0.025 | 0.02-0.04 | 0.9-1.2 | 0.15-0.3 |

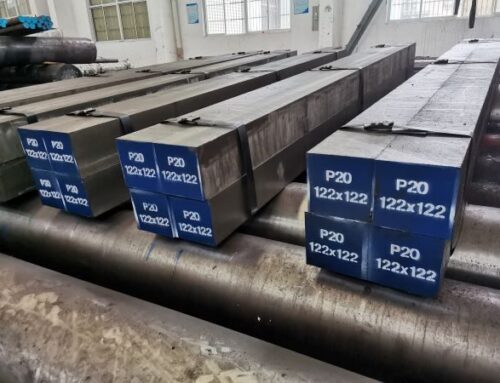

42CrMoS4 Forged Flat bars with QT condition

So the question is, why add sulfur? As a harmful element, isn’t it the lower the better?It is well known that sulfur will increase the hot brittleness of steel, reduce the strength and toughness of steel, and cause cracking.

However, steel with proper sulfur content can form more MnS with Mn element. In cutting, MnS can play a chip breaking effect and improve the machinability of steel. This is the beneficial side of sulfur, and free-cutting steel is a typical application.

How Hard is 42CrMo4 Steel?

42CrMo4 steel is generally supplied under hot-rolled or annealed conditions, and its hardness is usually lower than 241HB. It is difficult for such a hardness to have a good performance in the application of products.

If you want to take advantage of the characteristics of 42CrMo4 steel, it needs to be quenched and tempered to get satisfactory comprehensive performance. Its hardness is optional within 28-58HRC, but it is usually used between 28-34HRC.

The application of higher hardness of 42CrMo4 steel can be achieved by nitriding,it can get surface hardness 550-700HV3,with nitration hardness depth 0.1-0.6mm.

Is 42CrMo4 Steel Machinable?

Generally speaking, the higher the hardness, the more difficult it is to process.Therefore, for 42CrMo4 steel without heat treatment, the hardness is not high, and its processing is relatively easy. After soft anealing, 42CrMo4 steel is easier to process.

The hardness of 42CrMo4 steel after quenching and tempering is generally 300HB. Such a hardness is still very common for machining. As long as you choose a reasonable speed and tool, you can still process it with confidence.

Can 42CrMo4 Steel be Carburized?

42CrMo4 steel can be carburized, but it is not necessary to do so.With an average carbon content of 0.42%, 42CrMo4 is used as an alloy structural steel, suitable for quenching and tempering treatment, so as to obtain good comprehensive mechanical properties.

42CrMo4 Steel Vs 50CrMo4 Steel

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo4/1.7225 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | ≤ 0.025 | ≤ 0.035 | 0.9-1.2 | 0.15-0.3 |

| 50CrMo4/1.7228 | 0.46-0.54 | ≤ 0.4 | 0.5-0.8 | ≤ 0.025 | ≤ 0.035 | 0.9-1.2 | 0.15-0.3 |

From the above table,we can clearly see the difference in carbon content between 42CrMo4 and 50CrMo4, and there is no intersection at all.Due to the slight difference in carbon content,50CrMo4 steel is better than 42CrMo4 steel in strength and hardenability, but is relatively worse in terms of weldability and toughness.

In terms of application, 50CrMo4 steel can be used as forgings with higher strength or larger section than 42CrMo4 steel, such as large gears for locomotive traction, turbocharger transmission gears, rear axles, engine cylinders, 1200~2000m oil deep well drill pipe joints And fishing tools, etc.50CrMo4 can sometimes be used instead of quenched and tempered steel with higher nickel content.

HOW TO MANUFACTURE 42CRMO4/DIN1.7225 STEEL?

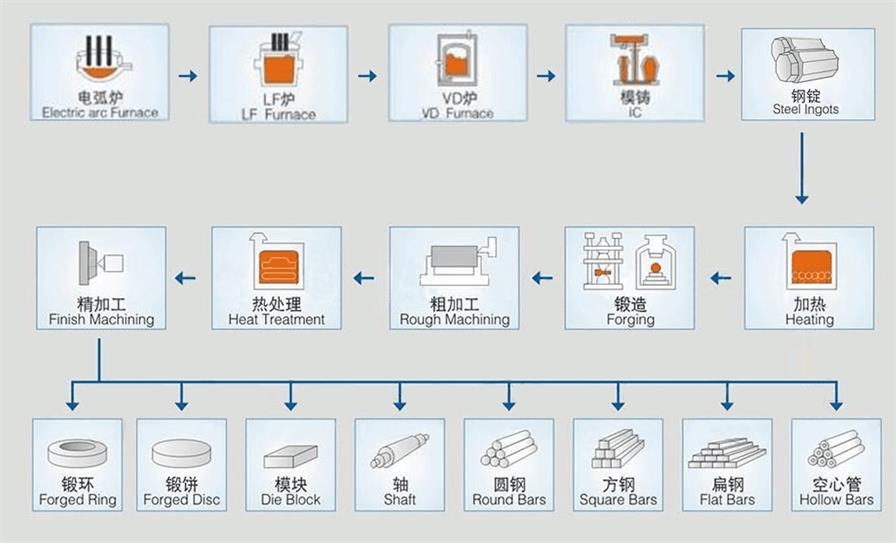

The process of manufacturing high-quality 42CrMo4 steel is a strict quality control process, and each step of the connection requires sufficient experience and strict quality control. From the figure below, we can roughly see a production flow chart.

Next, we will mainly talk about the following key points on the manufacture of 42CrMo4 steel.

- Smelting & Casting Technology

There are two mainstream methods for smelting and casting 42CrMo4, one is electric arc furnace smelting, secondary refining and vacuum degassing.The other is the converter steelmaking and continuous casting technology adopted by large steel mills.

The difference is that electric arc furnace steelmaking is suitable for small batch production, and the composition of molten steel is greatly affected by scrap steel.While converter steelmaking is suitable for mass production and has high purity of molten steel. Compared with electric arc furnace steelmaking, the smelting cycle is shorter and the power consumption is lower.

- Hot Processing Method

Corresponding to the smelting and casting technology, the 42CrMo4 steel ingots made by EAL+LF+VD are mainly used for hot forging processing, including free forging and die forging.

The 42CrMo4 billets made by converter + continuous casting technology are usually used as hot-rolled products, and the production efficiency is extremely high.

The last thing to note is that they can be applied to each other, but they must match the size of the billets to ensure a sufficient compression ratio.

- Preliminary Heat Treatment Process Selection

For 42CrMo4 steel, after hot rolling or hot forging, it can usually be delivered without heat treatment.However, sometimes considering the machinability of the material, 42CrMo4 steel is usually selected for soft annealing treatment.

The choice of 42CrMo4 normalizing is often to improve the processing performance, eliminate internal stress and prepare a good metallographic structure for the final heat treatment.

WHAT IS THE GAS CONTENT OF 42CRMO4 STEEL?

Gas in steel is the general name of oxygen, nitrogen, hydrogen and other gases in the medium absorbed by steel during smelting, welding or chemical and electrochemical reactions on the surface of steel. The gas in the steel has a harmful effect on the performance of the steel, and its content should be strictly controlled

- Oxygen in Steel

Steelmaking itself is an oxidation process. Although ferromanganese, ferrosilicon, aluminum and other deoxidizers are added in the later stage of steelmaking, some of the oxygen still dissolves in the solid steel.

Oxygen generally dissolves in ferrite, or forms oxides such as FeO, SiO2, MnO, Al2O3 (that is, non-metallic inclusions in steel), which reduces the tensile strength, plasticity and toughness of 42CrMo4 steel. Especially in the presence of inclusions, the fatigue strength of 42CrMo4 steel decreases and the hot and cold workability deteriorates.

Therefore, we must strictly adopt oxygen control technology, such as VD deoxidation, so that the oxygen content of 42CrMo4 steel is lower than 20ppm, or even lower.

- Nitrogen in Steel

When steelmaking, molten steel absorbs nitrogen in the air. One part is soluble in ferrite, and one part becomes non-metallic inclusions. When 42CrMo4 steel does not contain Al, Ti, Zr and other elements, most of the nitrogen and iron form a needle-like compound of Fe4 N. Although the presence of Fe4N increases the strength of 42CrMo4 steel, it drastically reduces its plasticity and toughness.

By preventing the LF nitrogen absorption technology and increasing the VD denitrification rate, the two methods can effectively reduce the nitrogen content, and can effectively control the nitrogen content below 90ppm.

- Hydrogen in Steel

The solubility of hydrogen in steel decreases significantly as the temperature drops. When hydrogen exists in an atomic state, it dissolves into the interstices of iron. When the dissolved hydrogen in steel exceeds 3 mL per 100 g, it will exist in a molecular state, and hair-like cracks appear on the internal cross section of the steel ingot or forging, which is called cracking. They look like oval silver-white spots, so they are also called white spots.

White spots make steel hydrogen embrittlement. It is not easy to form white spots in low-carbon steel, but medium-carbon alloy steel(such as AISI 1045 Steel,C55 Steel), especially medium-carbon Ni-Cr-Mo steel(Such as 34CrNiMo6 Steel,30CrNiMo8 Steel,AISI 4340 Steel), is most sensitive to hydrogen embrittlement.For 42CrMo4 steel,it is also easy to form white spots, causing the material to crack.

The VD vacuum degassing technology can effectively remove hydrogen. In order to avoid embrittlement, the 42CrMo4 steel can also be annealed at about 650℃ to allow hydrogen to diffuse out of the steel to eliminate the supersaturation state and achieve the purpose of hydrogen removal.Generally, the hydrogen content can be controlled below 2.0ppm

42CRMO4/DIN 1.7225 HEAT TREATMENT

42CrMo4/DIN 1.7225 Steel Normalizing & Annealing

When 42CrMo4 steel needs to improve its comprehensive performance, it is usually achieved through heat treatment.Before the final heat treatment, we first consider preliminary heat treatment,the conventional methods include normalizing and annealing.Next, let’s talk about the difference and characteristics of 42CrMo4 annealing and normalizing,and help us how to choose them when we face different requirements.

- Different Effect and Purpose

42CrMo4 normalizing is mainly to refine the grains, homogenize the structure, and prepare the structure for the final heat treatment.While the annealing timing of 42CrMo4 steel is generally placed after forging, hot rolling, and welding, mainly to reduce the internal stress of the material, soften the structure and improve the turning performance.

- Different Process comparison

| 42CrMo4 Normalizing | 42CrMo4 Annealing | |

| Temperature,℃ | 850-900 | 800-850 |

| Cooling | Air Cooling | Furnace Cooling |

| Cooling Speed Rate | Relatively fast | Slow |

| Grain size | Good | Normal |

| Machinability | Normal | Good |

| Deformation | Large | Relatively Small |

| Heat Treatment Cycle | Short time | Long time |

| Surface Hardness,HBW | 200-250 | ≤ 229 |

- Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness | |

| Normalizing | 1020Mpa | 655Mpa | 17.7% | 47% | 23 | 302HBW |

| Annealing | 655Mpa | 415Mpa | 25.7% | 57% | 55 | 197HBW |

42CrMo4/DIN 1.7225 Steel Quenching & Tempering(QT)

As the final heat treatment of 42CrMo4 steel, quenching and tempering is also the most commonly used heat treatment process. Let’s talk about the characteristics of this process.

- 42CrMo4/DIN 1.7225 Steel Quenching

For 42CrM04 steel, it is recommended to use quenching medium oil or water in accordance with the standard EN10083, but in actual production, the probability of using the two is roughly the same.In the following table we summarize and compare the differences between them

| Water Quench | Oil Quench | |

| Quench Medium | Water | Oil |

| Quench Temperature | 820~880℃ | 820~880℃ |

| Quench Time | Normal | Longer |

| Cooling ability | Better | Normal |

| Workpiece Shape | Simple | Relatively complex |

| Crack Resistance | Poor | Normal |

| Deformation | Bigger | Relatively small |

| Hardness | Higher | Relatively low |

| Hardenability | Better | Relatively Poor |

| Tempering Following | Immediately | Immediately |

- 42CrMo4/DIN 1.7225 Steel Tempering

The tempering of 42CrMo4 steel should be carried out immediately after quenching,especially after water quenching.The tempering holding time should be sufficient, otherwise it will cause too high hardness and insufficient quenching stress relief, which will easily cause cracking.

Tempering Temperature Vs Hardenss

| Tempering Temperature,°C | 200-250 | 400-450 | 450-500 | 500-550 | 560-600 | 600-640 |

| Hardness,HRC | 55 | 45 | 40 | 35 | 30 | 25 |

BUYING 42CRMO4/DIN1.7225 STEEL: WHICH MANUFACTURER SHOULD YOU WORK WITH?

The market is full of poor quality 42CrMo4 steel suppliers. Either the composition does not meet the standard or contains serious internal defects, which are shoddy, so please stay away from them.

However, the market still needs high-quality 42CrMo4 steel, so please cooperate with us,we are confident to provide world-class quality 42CrMo4 steels no matter what type of use you have for it!

What We Supply For 42CrMo4/DIN 1.7225 Steel

- Hot Rolled Round Bar:Φ20-Φ350mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ250mm,15 days Delivery

- Customized service:Special Size & Length,30 days Delivery

- Free Sample of 42CrMo4 Steel

DIN 1.7225 Hot Rolled steel with QT condition