As low-alloy structural steels of European standard grades, 42CrMo4 and 34CrNiMo6 are widely used in various industries and play an incomparably important role due to their excellent performance.

The equivalent grades of 42CrMo4 and 34CrNiMo6 are American Standard 4140 and 4340. We have introduced and compared 4140 and 4340 in the previous article ( please refer to: 4140 steel vs 4340 steel),so here we also discuss the differences between 42CrMo4 and 34CrNiMo6.

1.Chemical Composition

Whether it is the early German standard DIN17200 or the current European standards EN10083 and EN10250, we can see the two grades of 42CrMo4 and 34CrNiMo6. This shows that the use of these two grades is indeed very common.Then let’s take a look at their chemical composition details.

| Grade | C | Si | Mn | Cr | Ni | Mo | P | S |

| 42CrMo4 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | 0.9-1.2 | - | 0.15-0.3 | ≤ 0.025 | ≤ 0.035 |

| 34CrNiMo6 | 0.30-0.38 | ≤ 0.4 | 0.5-0.8 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 | ≤ 0.025 | ≤ 0.035 |

42CrMo4 and 34CrNiMo6, as European grades, follow the naming system rules under the EN10073 standard.Under this rule, let’s take a look, 42 in 42CrMo4 represents an average carbon content of 0.42%, and 4 represents an average Cr content of 4/4=1%. Similarly, 34 in 34CrNiMo6 represents an average carbon content of 0.34 %, 6 means that the average content of Cr and Ni is 6/4=1.5%. In addition, they all have a certain amount of Mo element.

For the above analysis, we can clearly make one-to-one correspondence from the above chemical composition table, and the differences can be said to be clear at a glance.

2.Manufacturing Cost

It can be clearly seen from the chemical composition in the above table that 42CrMo4 and 34CrNiMo6 are significantly different in the content of alloying elements Cr and Ni, which is also the main reason for the difference in their manufacturing costs.

Generally speaking, at the same level of electric arc furnace smelting,the manufacturing cost of 34CrNiMo6 steel is about 35% higher than that of 42CrMo4 steel.

3.Weldability

According to the carbon equivalent formula CE=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15, we can roughly estimate the equivalent values of 42CrMo4 and 34CrNiMo6. Considering that the chemical composition takes intermediate values, The CE value of 42CrMo4 is around 0.8, while that of 34CrNiMo6is around 0.89.

According to production experience, when the CE value is greater than 0.8, the weldability is very poor.Therefore, both 42CrMo4 and 34CrNiMo6 are materials that are difficult to weld.But relatively speaking, the weldability of 42CrMo4 is better than that of 34CrNiMo6.

4.Strength & Hardness

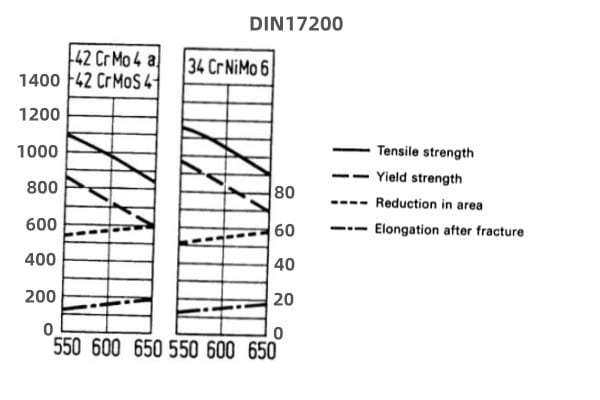

First of all, before talking about the strength difference, let’s look at the following data, which comes from the standards EN10083, EN10250 and DIN 17200.

| EN10083 | ||||||||||

| Grade | ≤16mm | 16-40mm | 40-100mm | 100-160mm | 160-250mm | |||||

| Rm,Mpa | Re,Mpa | Rm,Mpa | Re,Mpa | Rm,Mpa | Re,Mpa | Rm,Mpa | Re,Mpa | Rm,Mpa | Re,Mpa | |

| 42CrMo4 | 1100-1300 | ≥900 | 1000-1200 | ≥750 | 900-1100 | ≥650 | 800-950 | ≥550 | 750-900 | ≥500 |

| 34CrNiMo6 | 1200-1400 | ≥1000 | 1100-1300 | ≥900 | 1000-1200 | ≥800 | 900-1100 | ≥700 | 800-950 | ≥600 |

| EN10250 | ||||||

| Grade | ≤160mm | 160-330mm | 330-660mm | |||

| Rm,Mpa | Re,Mpa | Rm,Mpa | Re,Mpa | Rm,Mpa | Re,Mpa | |

| 42CrMo4 | ≥750 | ≥500 | ≥700 | ≥460 | ≥600 | ≥390 |

| 34CrNiMo6 | ≥800 | ≥600 | ≥750 | ≥540 | ≥700 | ≥490 |

Obviously, we can see that in the standard, in the quenched and tempered condition, the strength requirement of 34CrNiMo6 is higher than that of 42CrMo4, whether it is tensile strength or yield strength.This also shows that in practical applications, if higher strength is required, 34CrNiMo6 is more suitable than 42CrMo4.

Let’s talk about the difference in hardness between 42CrMo4 and 34CrNiMo6 after heat treatment.

| Grade | EN10083 | DIN17200 | |

| 42CrMo4 | +A | ≤241 HBW | ≤241 HBW |

| 34CrNiMo6 | +A | ≤248 HBW | ≤248 HBW |

As can be seen from the above table, under EN10083 and DIN17200 standards, the hardness values of 42CrMo4 and 34CrNiMo6 after softening annealing. This also means that they can be delivered in the annealed condition.

Another more common delivery state is pre-hardening, that is, quenching and tempering, which also involves the most important hardness after quenching and tempering.42CrMo4 and 34CrNiMo6 have a wide range of quenched and tempered hardness, but their most common hardness is usually 28-34HRC.

As a high-quality alloy steel manufacturer, we are confident that we have the ability to provide 42CrMo4 and 34CrNiMo6 products that meet European standards.If you have this demand, please feel free to contact us.