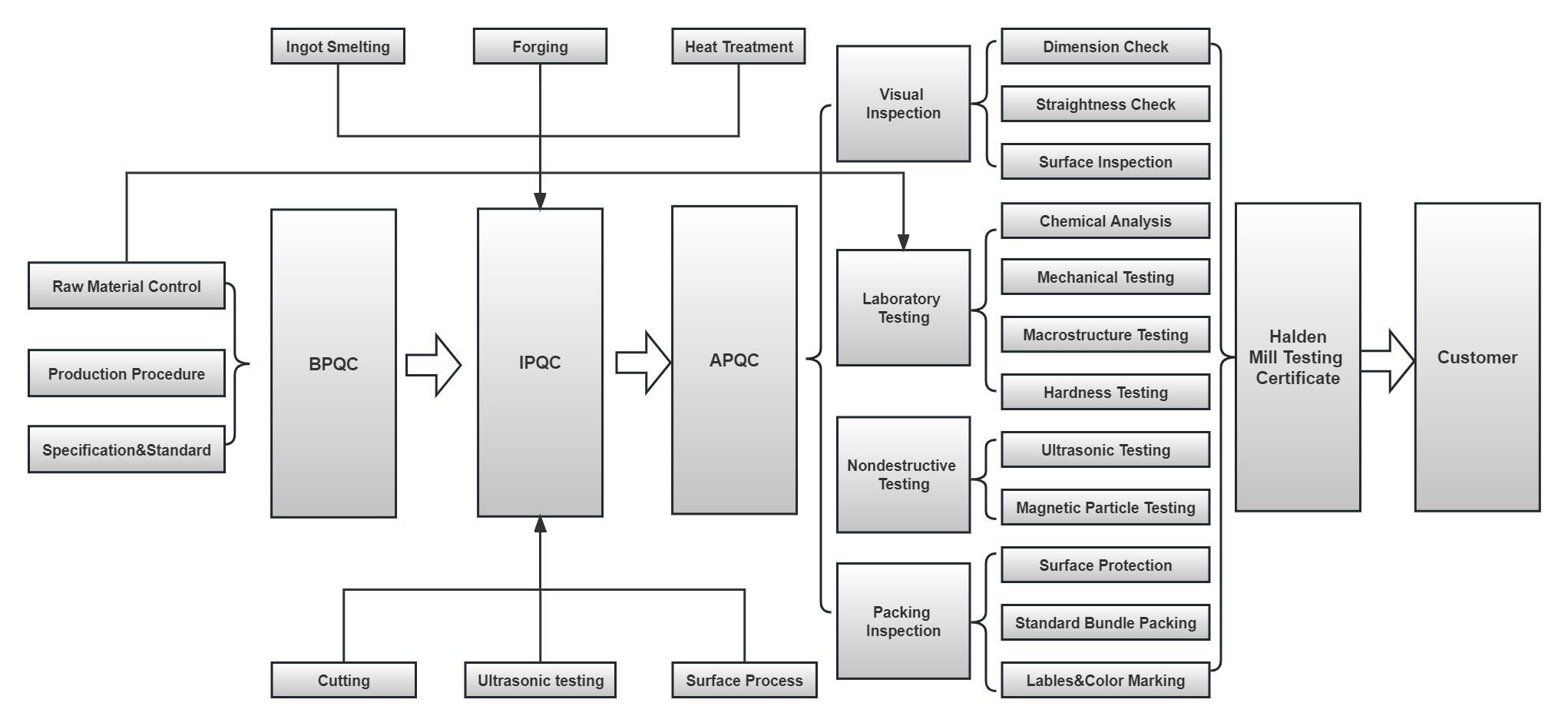

Quality Control System

Approved and certified by ISO 9001-2015,Fuhong has established a set of stable and high-efficiency quality management system which involves the whole production process from incoming raw material to final products, management, marketing and after-sales service.

Our quality department is an independent department which firmly believe that “quality is produced, not inspected”.Quality control is required in each step in quality management system. Quality consciousness is full integrated in Fuhong, not an individual. Product quality can be guaranteed only by enhancing the quality consciousness of all Fuhong employees. Fuhong quality management system support us to improve efficiency reduce costs and provide better quality products and service to enhance customer satisfaction.

In order to better control product quality,we generally carry out three procedures on quality control as below

Before Production Quality Control(BPQC)

- Raw Material Control

Raw materials for steel production inspection are carried out to make first important step of quality control

- Production Procedure

Check the production schedule provided by product department,and confirm the feasibility by our techniques

- Specification & Standard

Make research and study on the specification,ensure that every procedure will lead to the proper quality

In Production Quality Control(IPQC)

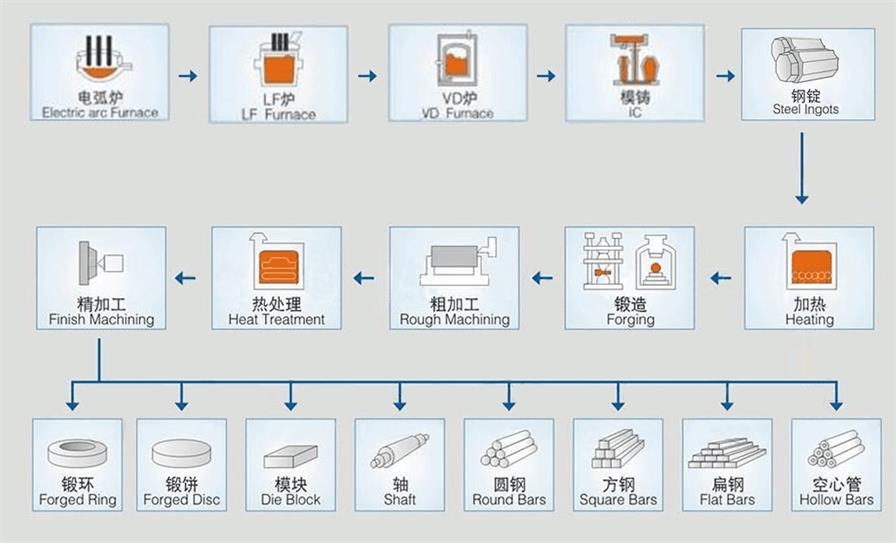

According to production procedure,IPQC are carried out to ensure production can meet the designated technical requirements.Do necessary tests during the production. Inspection hold point will be carried out during Smelting,Foring,Heat Treatment and Machining process to check whether the procedure is under control properly.

After Production Quality Control(APQC)

After the production of products,we will carry out quality inspection for final products.Testing results for each testing will be recorded to ensure that all products meet customer requirements.

Visual Inspection

- Dimension Checking

- Straightness Checking

- Surface Inspection

- Ends/Edges Inspection

Material Quality Testing

- Elements Analysis

- Mechanical Testing

- Hardness Tesing

- Grain Size Tesing

- Non-metallic Inclusion Testing

- Ultrasonic Testing

Delivery Packing Inspection

- Surface Protection

- Standard Bundles Packing

- Lable & Color Marking

Quality Control Procedure