As a German grade of cold work die steel, DIN 1.2767/X45NiCrMo4 steel is a medium carbon bainitic steel containing nickel, chromium and molybdenum,of which the nickel content reaches 4%.1.2767 steel is usually supplied in the annealed condition.

The Main Characteristics of DIN 1.2767/X45NiCrMo4 steel

- High toughness & hardness

- Good wear resistance

- High compressive strength

- Excellent dimensional stability

- Excellent corrosion resistance

- Good polishing and cutting performance, easy to achieve mirror effect

- Excellent hardenability, can be hardened by air cooling

- Excellent machinability

DIN 1.2767/X45NiCrMo4 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

DIN 1.2767/X45NiCrMo4 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 1.2767 | 0.4-0.5 | 0.1-0.4 | 0.15-0.45 | ≤ 0.03 | ≤ 0.03 | 1.2-1.5 | 3.8-4.3 | 0.15-0.35 |

DIN 1.2767/X45NiCrMo4 RELATED STANDARD & EQUIVALENT GRADE

Europe/EN:45NiCrMo16

France/AFNOR:45NCD16

USA: 6F7

DIN 1.2767/X45NiCrMo4 STEEL FORGING

- Initial Forging Temperature:1100-1200℃

- Final Forging Temperature:800-900℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high nickel tool steel,DIN 1.2767 steel should be annealed after forging.

DIN 1.2767/X45NiCrMo4 STEEL HEAT TREATMENT

- DIN 1.2767/X45NiCrMo4 Isothermal Annealing

Firstly, DIN1.2767 steel is heated to the austenitization temperature of 860°C and held for 1 hour, then cooled to 640°C at 30°C/h, held for the corresponding time, and finally cooled to room temperature with the furnace.

Generally speaking, as the isothermal time prolongs, the hardness will gradually decrease.The annealed hardness of DIN 1.2767 steel is usually below 262HB.

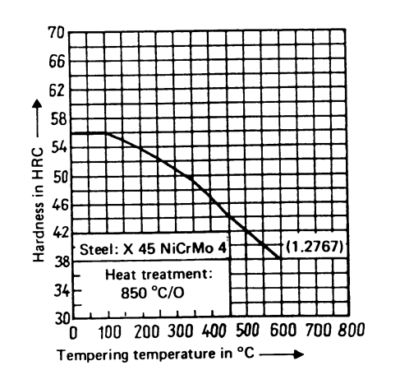

- DIN 1.2767/X45NiCrMo4 Quenching & Tempering

Quenching Temperature:840-870℃

Quenching Medium:oil

Tempering should be followed after quenched.Tempering twice is recommended.

DIN 1.2767 Steel Tempering vs Hardness Diagram

TYPICAL APPLICATIONS FOR DIN 1.2767/X45NiCrMo4 STEEL

Highly stressed coining tools with maximum toughness, tools for heavy cold-forming, highly stressed blanking dies, dies for jewellery, hobbing tools, shear blades for the thickest cutting material.