16MnCr5/DIN 1.7131 steel is a typical low carbon alloy (chromium-manganese series) case hardening steel as per European standard EN10084.

As a surface-hardened engineering steel, 16MnCr5 steel has good hardenability and machinability. After heat treatment, it can obtain higher surface hardness, good wear resistance and low-temperature impact toughness.

16MnCr5 steel is mainly used to manufacture gears, worm gears, seal sleeves, bolts and other mechanical engineering parts after carburizing and quenching.

16MnCr5 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr |

| 16MnCr5/1.7131 | 0.14-0.19 | ≤ 0.4 | 1.0-1.3 | ≤ 0.025 | ≤ 0.035 | 0.8-1.1 |

16MnCr5 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA:15CrMn

USA:5120

France:16MC5

UK:590M17

16MnCr5 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.89 |

| Melting point,℃ | 1445 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 481 |

| Linear expansion coefficient,10^-6/k | 12.59 |

| Poisson’s ratio | 0.28 |

| Elastic Modulus,Mpa | 211000 |

| Shear modulus,Mpa | 82600 |

| Thermal conductivity,W/(m.K) | 41(101℃) |

16MnCr5 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:>800℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As low carbon alloy steel,16MnCr5 steel is generally treated by slow cooling in sands after forging.

16MnCr5 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 16MnCr5 Steel

- Ac1:750℃

- Ac3:845℃

- Ms:400℃

Temperature Selection for Different Types of Heat treatment for 16MnCr5 steel

- Normalizing: 880 – 900°C,Cooling in air

- Annealing:860 – 900°C,Cooling in furnace,hardness below 179HBW

- Carburizing:880-980°C

- Core-hardening:860-900°C

- Case-hardening:780-820°C

- Tempering:150-200°C

16MnCr5 Steel Hardenability Limits

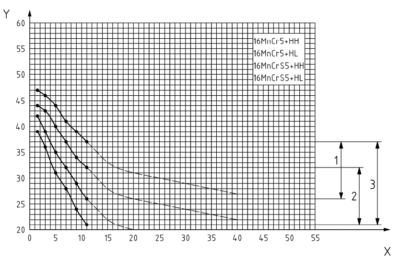

Jominy Quenching Test Curve For 16MnCr5 Steel

Quenching at 870°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

1: HH level

2: HL level

3: H level

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | |

16MnCr5+H | HRC Max | 47 | 46 | 44 | 41 | 39 | 37 | 35 | 33 | 31 | 30 | 29 | 28 | 27 |

| HRC Min | 39 | 36 | 31 | 28 | 24 | 21 | – | – | – | – | – | – | – | |

16MnCr5 Steel Mechanical Property with Quenched and Tempered Condition

| Quenching Temperature,ºC | Tempering Temperature,ºC | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| 880ºC, Oil Quench | 200ºC | ≥785 | ≥590 | ≥12 | ≥50 | ≥47 |

16MnCr5/DIN 1.7131 STEEL SUPPLY FORM & SIZE

Hot Forged Products

- Round : Dia.80 – 1,000mm

- Flat / Square : Thickness Max.800mm

- Rings,Tubes,Shafts, Rollers, Blocks: Customized or According to Drawing

Hot Rolled Products

- Round : Dia.14 – 280mm with Annealed Condition,UT quality assurance

- Other Shapes:Customized

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |