DIN 15CrNi6/1.5919 steel is a low carbon case hardened steel containing Cr-Ni alloying elements as per Germany standard DIN 17210.

As a Cr-Ni series low alloy steel, after carburizing, quenching and low temperature tempering, the surface of DIN 15CrNi6 steel exhibits high fatigue strength, high hardness and wear resistance, and at the same time the core maintains high toughness.

Due to its excellent comprehensive mechanical properties,15CrNi6 steel is mostly used in gear components,and it is also used in the wind power industry.

DIN 15CrNi6 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni |

| 15CrNi6/1.5919 | 0.14-0.19 | ≤ 0.4 | 0.4-0.6 | ≤0.035 | ≤0.035 | 1.4-1.7 | 1.4-1.7 |

DIN 15CrNi6 STEEL RELATED STANDARD & EQUIVALENT GRADE

EN:17CrNi6-6/14CrNi6

ASTM:3115

DIN 15CrNi6 STEEL FORGING

- Initial Forging Temperature:1200℃

- Final Forging Temperature:800℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:As an alloy steel with 1.5% Cr and 1.5% Ni, 15CrNi6 steel has high white point sensitivity.Our experience is that annealing heat treatment after forging. It not only eliminates the sensitivity of white spots, but also improves the surface condition and facilitates subsequent processing.

DIN 15CrNi6 STEEL HEAT TREATMENT

Hardness of Different Types of treatment for 15CrNi6

- Treated for shearability:≤255HBW

- Treated for softened:≤217HBW

- Treated for strength: 170-217HBW

- Treated for ferrite/pearlite structure:152-201HBW

Temperature Selection for Different Types of Heat treatment for 15CrNi6

- Soft Annealing:650 – 700°C,Cooling in furnace

- Carburizing:880-980°C

- Core-hardening:830-870°C

- Case-hardening:780-820°C

- Tempering:150-200°C

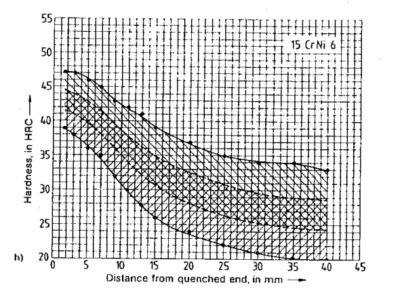

Jominy Quenching Test Curve For 15CrNi6 Steel

Quenching at 860°C

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | |

15CrNi6 | HRC Max | 47 | 47 | 46 | 45 | 43 | 42 | 41 | 39 | 37 | 35 | 34 | 34 | 33 |

| HRC Min | 39 | 38 | 36 | 35 | 32 | 30 | 28 | 26 | 24 | 22 | 21 | 20 | 20 | |

DIN 15CrNi6 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |