In the previous article, we compared the typical alloy steel representative steel grades in BS970 standard, EN19 vs EN24. Here, we continue to make a similar comparison between EN8 and EN9, the typical carbon steel grades in the BS970 standard.To be honest, this is meaningful and interesting work, so let’s get started.

1.Chemical Composition

Like EN19 and EN24, EN8 and EN9 also come from the BS970-1955 standard. Similarly, its naming is just a name and has no actual meaning at that time.

Later, the British Standardization Institute (BSI) updated the standard to BS970-1991. 080M40 and 070M55 are upgraded versions of EN8 and EN9 respectively, and their naming rules are well-documented. If you want to learn more, please refer to the previous article: “How to Buy EN19/709M40 Steel?” Or “How to Buy EN24/817M40 Steel?”

BS970-1955 Version

| Grade | C | Si | Mn | P | S |

| EN8 | 0.35-0.45 | 0.05-0.35 | 0.6-1.0 | ≤0.06 | ≤0.06 |

| EN9 | 0.5-0.6 | 0.05-0.35 | 0.5-0.8 | ≤0.06 | ≤0.06 |

BS970-1991 Version

| Grade | C | Si | Mn | P | S |

| 080M40 | 0.36-0.44 | 0.1-0.4 | 0.6-1.0 | ≤0.05 | ≤0.05 |

| 070M55 | 0.5-0.6 | 0.1-0.4 | 0.5-0.9 | ≤0.05 | ≤0.05 |

It can be seen from the above old and new versions that whether it is EN8 and EN9, or 080M40 and 070M55, the main elements Si and Mn are roughly the same, with almost no changes. As for the control of harmful elements P and S, the new version should be stricter.

The most obvious chemical element difference between EN8/080M40 and EN9/070M55 is the carbon content. The content of the former is about 0.15% lower than that of the latter, and there is no overlapping range.

2.Hardenability

To be honest, the hardenability of EN8 and EN9 is quite poor. The critical quenching diameter of EN8 in normal temperature water is about 18mm, while that of EN9 is about 20mm. Relatively speaking, the hardenability of EN9 is slightly better.

3.Wear resistance & Toughness

Due to its high carbon content, EN9 steel has higher surface hardness and strength than EN8 steel after heat treatment, so its wear resistance is also better than EN8 steel.However, EN9 steel is only hard and brittle, and its plasticity and toughness are even worse than EN8 steel.

4.Weldability

According to the carbon equivalent formula to measure the ease of welding, the CE value of EN8 steel is about 0.53, while that of EN9 steel is about 0.67.There is no doubt that the welding performance of EN8 steel is obviously better than that of EN9 steel.However, this is only theoretical, and actual operation must be based on correct welding process procedures.

5.Strength & Hardness

According to the BS970-55 standard, we can summarize the relationship between strength and hardness in normalized and hardened and tempered condition.

- EN8 VS EN9 Normalized Condition

| Grade | Tensile,Mpa | Corresponding Hardness,HBW |

| EN8 | ≥540 | 152-207 |

| EN9 | ≥695 | 201-255 |

- EN8 VS EN9 Hardened &Tempered Condition

| EN8 | EN9 | ||||

| Symbol | Tensile,Mpa | Corresponding Hardness,HBW | Symbol | Tensile,Mpa | Corresponding Hardness,HBW |

| Q | 625-775 | 179-229 | R | 700-850 | 201-255 |

| R | 700-850 | 201-255 | S | 775-925 | 223-277 |

| T | 850-1000 | 248-302 | |||

EN8 VS EN9 Hardness Comparison At Different Tempering Temperatures

| Grade | Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC | |

| EN8 | 840ºC | 54-55 | 55 | 53 | 48 | 42 | 34 | 29 | 23 | 20 |

| EN9 | 820ºC | 62-63 | 63 | 56 | 50 | 45 | 34 | 30 | 24 | 21 |

Based on the above analysis, we can see that the strength and hardness of EN9 steel is higher than that of EN8 steel, whether in normalizing or quenching and tempering conditions.

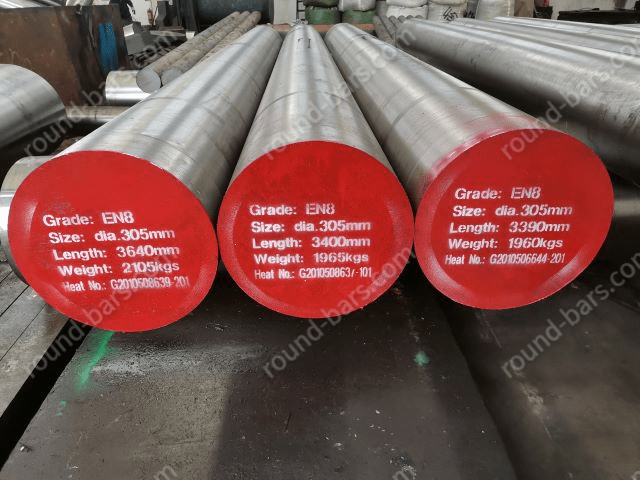

As a supplier of high-quality steel EN8 steel and EN8 steel, we are willing to provide customers with high-quality products and services. If you have this demand, please feel free to contact us.