EN8/080M40 steel,as ’40’ carbon steel, is a common unalloyed medium carbon steel as per British standard BS 970.It has medium carbon content with 0.36-0.44% which gives it medium tensile strength.EN8 steel is generally supplied in untreated condition or normalized condition,and also suitable in the hardened and tempered condition for tensile ranges of 625-775 Mpa(Q),and 700-850Mpa(R). For further process,it can be flame or induction hardened to produce a good surface hardness(50-55HRC) and moderate wear resistance.With good homogenous metallurgical structures which gives stable machining properties, EN8 material can be easily machined in any condition.

1.Supply Form & Size & Tolerance

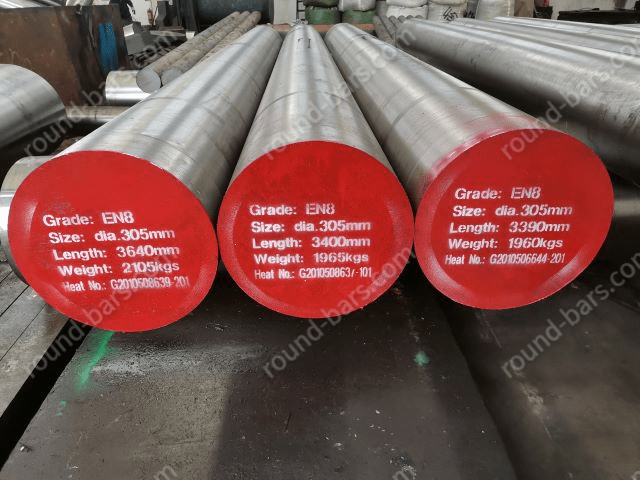

Hot Forged Round bar:Φ80-Φ1000mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Si | Mn | P | S |

| EN8 | 0.35-0.45 | 0.05-0.35 | 0.60-1.0 | ≤ 0.06 | ≤ 0.06 |

| 080M40 | 0.36-0.44 | 0.1-0.4 | 0.60-1.0 | ≤ 0.05 | ≤ 0.05 |

EN8 Series For Speical Applications:EN8A,EN8B,EN8C,EN8D,EN8E,EN8K

| Grade | C | Si | Mn | P | S |

| EN 8A | 0.33-0.38 | 0.05-0.35 | 0.70-0.9 | ≤0.06 | ≤0.06 |

| EN 8B | 0.35-0.40 | 0.05-0.35 | 0.70-0.9 | ≤0.06 | ≤0.06 |

| EN 8C | 0.38-0.43 | 0.05-0.35 | 0.70-0.9 | ≤0.06 | ≤0.06 |

| EN 8D | 0.40-0.45 | 0.05-0.35 | 0.70-0.9 | ≤0.06 | ≤0.06 |

| EN 8E | 0.35-0.40 | 0.05-0.35 | 0.9-1.1 | ≤0.06 | ≤0.06 |

| EN 8K | 0.35-0.45 | 0.05-0.35 | 0.6-1.0 | ≤0.05 | ≤0.05 |

EN8 Series For Free Cutting:EN8M,EN8AM,EN8BM,EN8CM,EN8DM

| Grade | C | Si | Mn | P | S |

| EN 8M | 0.35-0.45 | ≤0.25 | 1.0-1.3 | ≤0.06 | 0.12-0.20 |

| EN 8AM | 0.33-0.38 | ≤0.25 | 0.9-1.3 | ≤0.06 | 0.12-0.20 |

| EN 8BM | 0.35-0.40 | ≤0.25 | 0.9-1.3 | ≤0.06 | 0.12-0.20 |

| EN 8CM | 0.38-0.43 | ≤0.25 | 0.9-1.3 | ≤0.06 | 0.12-0.20 |

| EN 8DM | 0.40-0.45 | ≤0.25 | 0.9-1.3 | ≤0.06 | 0.12-0.20 |

3.Relevant Standards

| USA | EN/DIN | Japan |

| 1040/1045 | C40/CK40/C45/CK45/1.0511/1.1186/1.1189 | S40C/S45C |

4. Mechanical Property

Condition | Normalized | Hardened & Tempered | |||

| N | Q | R | |||

| Tensile Strength,Mpa | ≥540 | ≥540 | ≥620 | ≥700 | ≥700 |

| Yield Strength,Mpa | ≥ 280 | ≥540 | ≥435 | ≥495 | ≥495 |

| Elongation | ≥20% | ≥20% | ≥22% | ≥20% | ≥20% |

| ISO V Impact,J | ≥28 | ≥20 | ≥34 | ≥54 | ≥34 |

| Hardness,HBW | 152-207 | 152-207 | 179-229 | 201-255 | 201-255 |

EN8 Round steel Lab Tesing Data with Normalizing condition

| Diameter,mm | Tensile Strength MPa | Yield Strength MPa | Elongation % | Hardness,HB |

| Φ460 | 675 | 375 | 25 | 179-187 |

| Φ510 | 620 | 360 | 28 | 135-167 |

| Φ600 | 615 | 355 | 27 | 124-156 |

5.Forging EN8/080M40 steel

Forging temperature around 1200℃,but don’t forge below 800℃,EN8 steel should be cooled as slowly as possible in still air(may get fine grain) or in sand after forged.

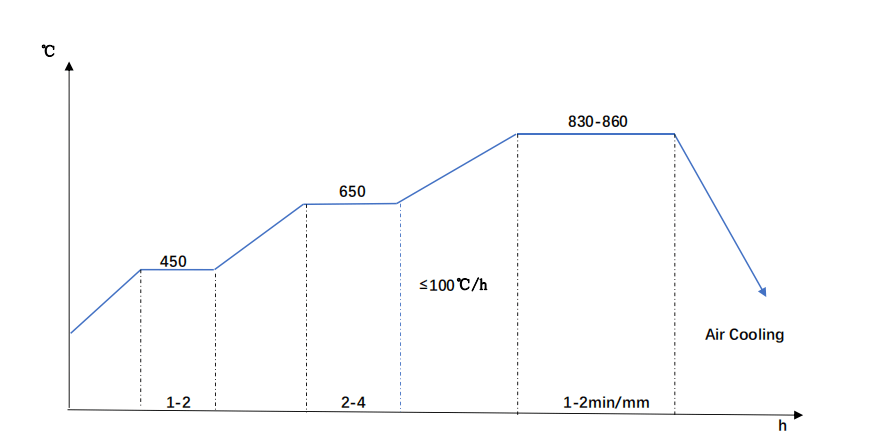

6.Heat Treatment

- Normalizing

Heat the steel to the temperature 830-860ºC ,keep the temperature depend on the steel size, then followed by cooling in still air.

EN8/080M40 Normalizing Diagram

- Annealing

Heat EN8 steel slowly to 680-710°C, keep the temperature stable . Cool slowly in the furnace.

- Hardening

Hardening of this grade is carried out from an austenitizing temperature of 820-860ºC followed by oil or water quenching.

- Tempering

Carbon steel EN8 or 080m40 can be tempered at a heat of between 550°C to 660°C,heating for about 1 hour for every inch of thickness, then cool in oil or water.

7.Application

EN8 steel is widely used in industries which is used in applications where better properties than mild steel are required.

Typical Applications:

- Automotive parts

- Connecting rods

- Studs, bolts

- Axles, spindles

- General engineering components