AISI 410 steel is defined as stainless steel containing at least 11.5% Cr element as per USA standard ASTM A959.

As one of the commonly used martensitic stainless steels, unlike austenitic grades such as AISI 304 and AISI 316,AISI 410 steel is magnetic,and has moderate corrosion resistance, good machinability and good mechanical properties such as tensile strength, creep and fatigue strength.Typically, these properties can be further enhanced by heat treatment,such as hardening,tempering.

AISI 410 steel is usually delivered in the annealed condition.It is not suitable for use in harsh corrosive environments, usually used for general knife blades, mechanical parts, class 1 tableware (spoons, forks, knives, etc.).

WHAT DOES AISI 410 MEAN?

To understand this problem, we must first understand the naming rules of stainless steel grades in the United States.

There are many ways to express steel grades in the United States, while AISI grades are generally used to express stainless steel. At present, ASTM stainless steel standards mainly use UNS (Unifid Numbering System for Metals and Alloys) and AISI two grade representation methods, which are listed in the standard, and will gradually transition to the UNS grade series in the future.

Next, we briefly introduce these two methods.

AISI:represented by three Arabic numerals in the below. The first digit indicates the category, and the second and third digits indicate the sequence number.

X X X

First Digit Category

2XX—-Cr-Mn-Ni series austenitic stainless steel

3XX—Cr-Ni series austenitic stainless steel

4XX—High chromium ferritic and martensitic stainless steel

5XX—Low chromium martensitic stainless steel

6XX—Precipitation hardened stainless steel

UNS:Represented by a combination of a prefix letter and 5 Arabic numerals in the below. The prefix letter of stainless steel is S, the first digit represents the category, and the last four digits represent the sequence number.

S X X X X X

In the first digit category, except for the number 1,the remaining first three digits basically use the AISI grade representation method.

First Digit Category

S1XXXX—Precipitation hardened stainless steel

S2XXXX—Cr-Mn-Ni series austenitic stainless steel

S3XXXX—Cr-Ni series austenitic stainless steel

S4XXXX—High chromium ferritic and martensitic stainless steel

S5XXXX—Low chromium martensitic stainless steel

The last two digits are generally “00”, “03” means ultra-low carbon.Other numbers are used to indicate that the main chemical composition is the same and the individual composition is slightly different, or that it contains other special alloying elements.

Here, we should clearly understand the meaning of AISI 410, 4 means it is a high Cr martensitic stainless steel in AISI system, and 10 means its sequence number.We can look at its specific chemical composition as below.

AISI 410 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr |

| 410/S41000 | 0.08-0.15 | ≤1.0 | ≤1.0 | ≤ 0.04 | ≤ 0.03 | 11.5-13.5 |

AISI 410 STEEL EQUIVALENT GRADE

China:12Cr13/1Cr13

Europe:X12Cr13/1.4006

Japan:SUS410

AISI 410/S41000 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.7 | |

| Melting point,℃ | 1480-1530 | |

| Specific heat capacity,(0~100℃),kj/(kg.k) | 0.46 | |

Thermal conductivity W/(m.K) | 100℃ | 500℃ |

| 24.2 | 28.9 | |

Linear expansion coefficient,10^-6/k | 0~100℃ | 0~500℃ |

| 11.0 | 11.7 | |

| Resistivity(20℃),Ω.mm2/m | 0.57 | |

| Longitudinal modulus of elasticity (20℃),kN/mm2 | 200 | |

| Magnetic | Magnetic | |

AISI 410 STEEL HEAT TREATMENT CRITICAL TEMPERATURE

- Ac1:730℃

- Ac3:850℃

- Ar1:700℃

- Ar3:820℃

- Ms:350℃

AISI 410 STEEL FORGING

- Forging temperature selection

As a martensitic stainless steel, the heating temperature of AISI 410 steel should not be too high. If the structure is too high, δ type ferrite will appear, which will reduce the plasticity of the steel and easily cause cracks at the two-phase interface. Therefore, the initial forging temperature of AISI 410 stainless steel is generally 1100~1150℃.

The terminal temperature should not be too low. If the temperature is too low, the plasticity of the steel will decrease greatly, and forging cracks will easily occur.Therefore, the final forging temperature of AISI410 steel should not be lower than 900℃.

- Heating requirements

AISI 410 martensitic stainless steel has poor thermal conductivity. In order to prevent the billet from cracking, in actual production, the temperature of the billet into the furnace should be lower than 400 °C. At the same time, it should be heated slowly before 850 ℃, and then it can be quickly heated to the initial forging temperature.

The residence time of AISI 410 steel in the high temperature area should not be too long, otherwise it will easily cause severe overoxidation, element depletion and grain coarsening.

- Post-Forging Treatment

AISI 410 martensitic stainless steel is particularly sensitive to the cooling rate. The martensitic structure can be obtained by air cooling, so that there are large thermal stress, structural stress and residual stress in the forging, which is easy to cause surface cracks, so it should be cooled slowly after forging.

Generally, AISI 410 steel is cooled in a furnace or an asbestos incubator with a temperature of about 200℃.The recommended practice is to transfer the material into an annealing furnace, hold it and then cool it down in the furnace.

AISI 410/S41000 STEEL HEAT TREATMENT

- Interprocess(subcritical temperature) Annealing:650-670℃,Hardness:86-92HRB

- Recrystallization(complete) Annealing:830-885℃,Hardness:75-85HRB

- Isothermal Annealing:Heating to 830-850℃,Holding 6 hours at temperature 705℃.Hardness<85HRB.

- Hardening:1000-1050℃,water/oil quench,Hardness:380-400HBS

- Tempering:700-750℃,fast cooling,Hardness:223-300HB

AISI 410 Tempering Temperature Vs Hardness

- Tempered at 580-650℃, water-cooled, Hardness:254-302HBS

- Tempered at 560-620℃, water-cooled, Hardness:285-341HBS

- Tempered at 550-580℃, water-cooled,Hardness:254-362HBS

- Tempered at 520-560℃, water-cooled, Hardness:341-388HBS

- Tempering at <300℃, air cooling,Hardness:>388HBS

AISI 410/S41000 Steel Mechanical Property with Quenched and Tempered Condition

Quenching Temperature:1000-1050℃

Quenching Medium:Water/oil

Tempering Temperature:700-790℃

Cooling Medium:oil/water/air

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction of Area,% | Impact Charpy-V,J | Hardness,HBW |

| ≥600 | ≥420 | ≥20 | ≥60 | ≥90 | ≥187 |

AISI 410/S41000 STEEL APPLICATION

As a semi-martensitic stainless steel, AISI 410 steel has high strength, toughness, good corrosion resistance and machinability after being quenched and tempered.

AISI 410 Steel is mainly used for parts that are not easy to rust, have high toughness requirements, and are resistant to impact loads, such as cutting tools, blades, fasteners, hydraulic press valves, thermal cracking and sulfur-resistant corrosion-resistant equipment, etc.It can also be used to make equipment and components that are resistant to weak corrosive media at room temperature.

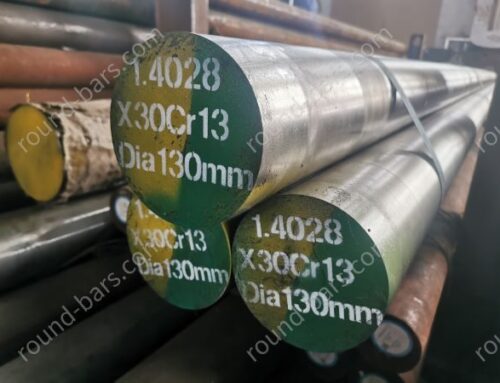

AISI 410/S41000 STEEL SUPPLY FORM & SIZE & TOLERANCE

Round bar: Dia 16-200mm As rolled

Round bar: Dia 80-400mm As forged

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Other shapes for AISI 410 Steel,such as plate,flat,shaft,ring,tube can be customized.