DIN 1.2510 steel is defined as low alloy (containing manganese, chromium, tungsten) high carbon Oil-hardened cold work tool steel.

DIN 1.2510 steel has good toughness and impact resistance while maintaining high hardness and strength.With excellent quenching performance, DIN 1.2510 steel will still maintain excellent shape and dimensional stability at high temperatures, and its thermal fatigue resistance is especially outstanding.In addition, it also has good wear resistance.

Generally,DIN 1.2510 steel is delivered in annealed condition with hardness below 229HBW.

DIN 1.2510 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | V | W |

| 1.2510 | 0.90-1.05 | 0.15-0.35 | 1.0-1.2 | ≤0.03 | ≤0.03 | 0.5-0.7 | 0.05-0.15 | 0.5-0.7 |

DIN 1.2510 STEEL RELATED STANDARD & EQUIVALENT GRADE

China:9CrWMn

USA:O1

Japan:SKS3

DIN 1.2510 STEEL FORGING

- Initial Forging Temperature:1000–1100℃

- Final Forging Temperature: above 850℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high carbon tool steel,DIN 1.2510 steel should be annealed after forging.

DIN 1.2510 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of DIN 1.2510 Steel

- Ac1:750℃

- Ac3:900℃

- Ar1:710℃

- Ms:230℃

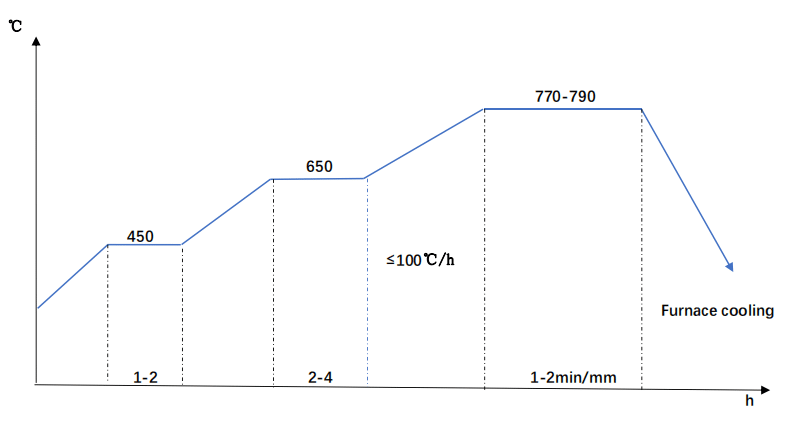

DIN 1.2510 steel Annealing

There are two annealing methods for DIN 1.2510 steel. The first method is to heat the temperature to 770-790, hold it for 3-6 hours, and finally cool the furnace to 500-600℃ with the rate 30℃/h max.The second method is to heat to 780-800°C, keep warm for 2-3 hours, and then control the temperature at 670-720°C with time for 3-4 hours.Finally cooling to below 500-600°C with the rate 30℃/h max in the furnace.These two annealing methods can make the hardness of 1.2510 steel generally lower than 229HBW.

DIN 1.2510 Steel Annealing Diagram

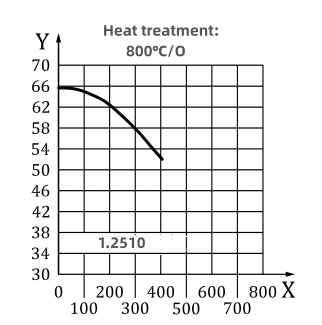

DIN 1.2510 steel Quenching & Tempering

Pre-heat Temperature:650℃

Quenching Temperature:800-840℃

Quenching Medium:oil

Quenching Hardness:64-66HRC

Tempering Temperature:150-200℃ Followed by Quenching

Hardness:Min 60HRC

DIN 1.2510 Steel Tempering vs Hardness Diagram

DIN 1.2510/100MnCrV4 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |