AISI 1045 MEDIUM CARBON STEEL – THE COMPREHENSIVE FAQ GUIDE

AISI 1045 steel, as a high-quality carbon structural steel, is mostly available in the market for hot rolled condition which is same as AISI 1020 low carbon steel.Due to its wide application in the field of industrial machinery manufacturing,every steel manufacturer can supply it, resulting in uneven material quality.For customers who want to buy AISI 1045 steel, how to select qualified materials is a difficult challenge.

From our FAQ guide, We can help you understand the important information and knowledge of 1045 steel, and help you choose and buy the right material for you need.

WHAT DOES 1045 STEEL MEAN?

1045 steel is used by both the American Iron and Steel Institute (A.I.S.I.) and the Society of Automotive Engineers (S.A.E.):AISI or SAE 1045.In order to replace or supplement the current standard product grade system, they jointly designed a simple numbering system: Unified Numbering System,referred to as UNS. In the UNS,we can find UNS G10450, it is the number for AISI 1045 steel.

For 1045, The first number ‘1’ indicates that the steel is Carbon steel,the second number ‘0′ means that the steel has no important alloy elements,the last two numner’45’ show that this steel has 0.45% carbon content.

From the ASTM A29 Standard,we can see many series,incluing carbon and alloy steel.As a member of the 104X series,1045 steel is the most commonly used,next commonly used is AISI 1040 steel.

104X Series Chemical Composition Comparison

| Grade | C | Mn | P | S |

| 1040 | 0.37-0.44 | 0.60-0.90 | ≤0.04 | ≤0.05 |

| 1042 | 0.40-0.47 | 0.60-0.90 | ≤0.04 | ≤0.05 |

| 1043 | 0.40-0.47 | 0.70-1.00 | ≤0.04 | ≤0.05 |

| 1044 | 0.43-0.50 | 0.30-0.60 | ≤0.04 | ≤0.05 |

| 1045 | 0.43-0.50 | 0.60-0.90 | ≤0.04 | ≤0.05 |

| 1046 | 0.43-0.50 | 0.70-1.00 | ≤0.04 | ≤0.05 |

| 1049 | 0.46-0.53 | 0.60-0.90 | ≤0.04 | ≤0.05 |

WHAT IS THE ALTERNATIVE TO AISI 1045 STEEL INTERNATIONALLY?

As we all know, AISI 1045 steel is a medium-carbon structural steel with good cold and hot workability, good mechanical properties.Because of its low price and wide supply sources, it is widely used in the industrial machinery manufacturing industry.

Generally speaking, a simple substitution of one material for another material will not produce a more optimal solution than the original one.Material substitution can provide opportunities to reduce costs or improve design, provided that the substitute material must fully meet the corresponding economic, physical and chemical requirements.

For AISI 1045 steel ,each country has its own alternative steel grade to meet the actual production needs of the domestic industry.

Here are some other distinctions and designations of this popular steel from main national countries.

| Standard | Grade | C | Si | Mn | P | S | Cr |

| GB 699 | 45# | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.25 |

EN 10083-2 | C45/1.0503 | 0.42-0.50 | ≤0.04 | 0.50-0.90 | ≤0.045 | ≤0.045 | ≤0.4 |

| C45E/1.1191 | 0.42-0.50 | ≤0.04 | 0.50-0.80 | ≤0.03 | ≤0.035 | ≤0.4 | |

| JIS G4051 | S45C | 0.42-0.48 | 0.15-0.35 | 0.60-0.90 | ≤0.03 | ≤0.035 | - |

BS 970 | EN8 | 0.35-0.45 | 0.05-0.35 | 0.60-1.0 | ≤0.06 | ≤0.06 | - |

| 080M40 | 0.36-0.44 | 0.1-0.4 | 0.60-1.0 | ≤0.05 | ≤0.05 | - |

IN WHICH FORMS AND CONDITIONS ARE AISI 1045 STEEL SUPPLIED IN THE MARKET?

AISI 1045 steel, as a widely used medium carbon steel, is generally supplied in a hot-rolled condition in the market, most of which are hot-rolled round steel and hot-rolled steel plate. The size for common hot-rolled round steel ranges from 20-350mm in diameter, and the thickness of hot-rolled steel plates ranges from 5-200mm.

AISI 1045 steel will also be supplied in a normalized condition.The advantage is that the structure and properties of the steel are uniform. Compared with the annealed steel, due to the fast cooling rate, the amount of pearlite in the steel structure increases, and the pearlite layers and the grains of the steel are refined. Therefore, it has higher comprehensive mechanical properties and can be further heat treatment for final product.

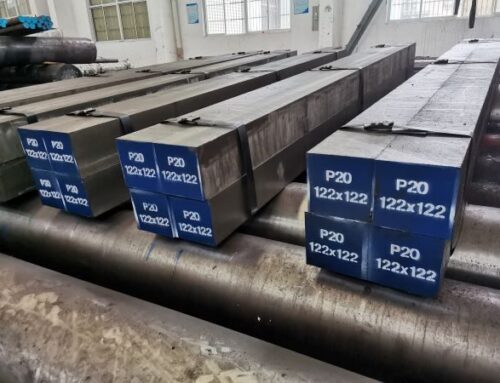

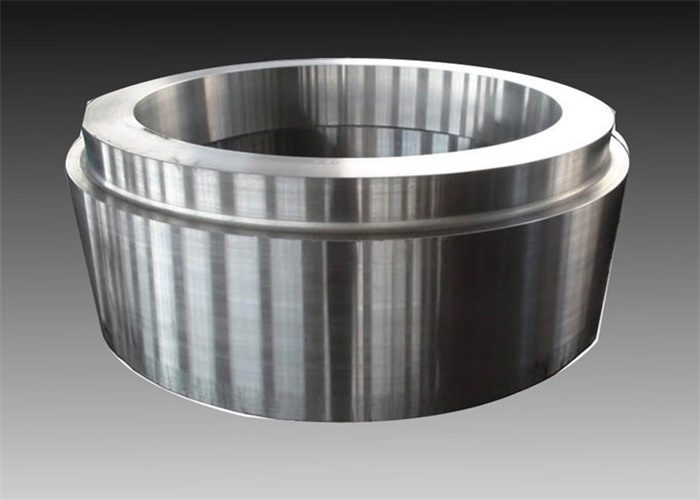

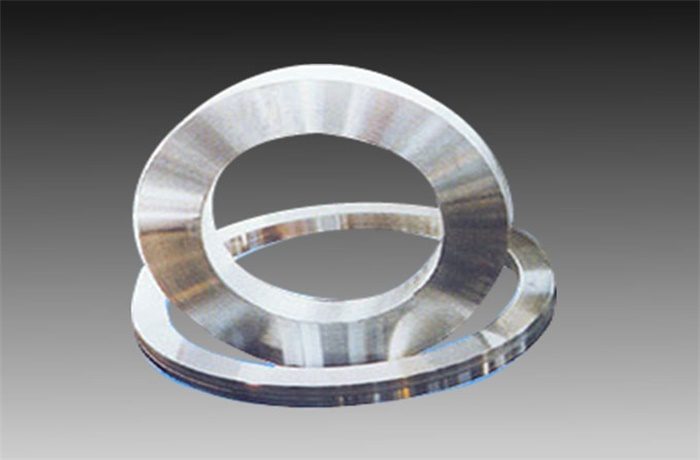

In addition to hot-rolled supply,AISI 1045 steel also can be cold drawn and hot forged to meet the various needs of customers.For AISI 1045 cold drawn steel,the conventional cold drawn size ranges from diameter 4-100mm, and the accuracy can reach h11 level.For hot forged product of this steel ,AISI 1045 can be supplied with rounds,squares,flats, rings,shafts,tubes,blocks,and other complex shapes.

AISI 1045 Steel Products

QUICK QUESTIONS FOR AISI 1045 STEEL

Is AISI 1045 Steel Mild Steel?

The term “Mild Steel” is very common in the iron and steel industry. It refers to a kind of low carbon steel with a carbon content of 0.15% to 0.30% and a Mn content of not more than 0.75%.Mild steel, you can guess by its name, it has low strength, low hardness and softness.

However,AISI 1045 steel steel has a carbon content of about 0.45%. It is a high-quality medium-carbon structural steel and is not a kind of mild steel.

Is AISI 1045 Steel Easily Machined?

AISI 1045 steel machinability can be done by following some considerations.It can be machined very nicely in the annealed or normalized condition using appropriate feeds, tool type, and speeds during operational activities like tapping, broaching, milling, drilling, turning, and sawing. Naturally since it’s a higher carbon steel its machineability (lb of chips per unit of power and time) is less than for mild steel,such as AISI 1020 steel.

Is AISI 1045 Steel Weldable?

Generally speaking, as a medium carbon steel, AISI 1045 steel has relatively poor welding performance, but it is a relatively good welding performance in medium carbon steel.It is suitable for hydrogen welding, argon arc welding, not suitable for gas welding.

Due to the medium carbon content, welding is easy to cause cracks. To avoid this, preheat to a certain temperature before welding (usually 150-250°C, if the material thickness or rigidity is large, it can be increased to 250-400°C) , Components with large thickness or rigidity, or workpieces used under harsh working conditions, it should be subjected to stress relief heat treatment immediately after welding, and the temperature should be controlled at 600-650°C

What is the Rockwell hardness of AISI 1045 Steel?

AISI 1045 Steel is medium carbon steel containing approximately 0.45% carbon that can be hardened by heat treatment to a maximum surface hardness of approximately Rockwell C 54-60 after flame or induction hardening.

Can AISI 1045 steel be Quenched and Tempered?

The weakness of 1045 steel is its low hardenability. For workpieces with large cross-sectional dimensions and high requirements, 1045 steel should not be used.

AISI 1045 steel generally uses water with higher thermal conductivity as the quenching medium.The quenching temperature of 1045 steel is A3+(30~50)℃,the hardness of 1045 steel after quenching should reach HRC56~59. Materials with large cross-sections may be lower, but not lower than HRC48.

1045 steel is tempered at high temperature after quenching, the heating temperature is usually 560~600℃, and the hardness requirement is generally HRC22~34, so as to obtain good comprehensive mechanical properties.

Is AISI 1045 Steel Suitable For Knives?

Although there is not enough carbon to harden 1045 to knife requirements for edge retention and durability, it is generally used in knife making since it can forge welds to other steels more quickly than AISI 1018 (mild) steel.

HOW TO SMELT AISI 1045 STEEL?

AISI 1045 steel, as a popular representative carbon steel grade, is of high quality and low price, with a wide range of sources, and its smelting method can also be said to be representative.

AISI 1045 steel mainly has two methods: Electric Arc Furnace smelting process and converter steelmaking process.

Electric arc furnace, refers to EAF,the process for AISI 1045 Steel as below

Electric Arc Furnace→Secondary Refining→ Continuous Casting/Ingot Casting→Hot Rolling/Forging

While converter steelmaking(LD),is also called Basic Oxygen Furnace(BOF).The BOF method is an abbreviation of the oxygen top-blown converter steelmaking method in North America.The process as below

Blast Furnace → Converter → Secondary Refining → Continuous Casting/Ingot Casting → Hot Rolling/Forging

There are significant differences between electric arc furnace and converter steelmaking in terms of raw materials, furnace temperature, smelting cycle, and single furnace scale.

The electric arc furnace uses scrap steel as the main raw material, and can precisely control the temperature of molten steel by adjusting the current. It is suitable for smelting small batches/variety of special steels. However, the quality of molten steel is greatly affected by scrap, the smelting cycle is relatively long, and the power consumption is relatively large.

While The converter uses the molten iron produced by the blast furnace as the main raw material, so the converter steelmaking molten steel has higher purity and less impurity alloy elements.The purity of molten iron can be controlled: [S] ≤0.005%, [P] ≤0.01%,also the gas content of the converter molten steel is low, N≤20ppm, H≤3ppm.

Compared with electric arc furnace steelmaking, the smelting cycle is shorter, the power consumption is lower, and the production rhythm is faster.It is suitable for steel grades with low carbon/ultra-low carbon and low residual elements, especially steel grades with large batches and low alloy content.

WHAT IS CARBURIZING PROCESS?

Carburizing,refers to a chemical heat treatment process of infiltrating carbon atoms into the surface layer of steel. The carburizing material is generally low-carbon steel or low-carbon alloy steel (with a carbon content of less than 0.25%).

After carburizing, the chemical composition of the surface of the steel can be close to that of high-carbon steel,and to maintain the strength and toughness of low-carbon steel in the core after quenching, so that the workpiece can withstand the impact load.

The carburizing process is widely used for mechanical parts such as gears, shafts, and camshafts of airplanes, automobiles, and tractors.

Can AISI 1045 Steel Be Carburized?

Yes,AISI 1045 Steel can be carburized,but not applicable.After carburized,it can increase the surface carbon content of the material,but hard and brittle martensite will appear in the core after quenching,core impact performance will be worse,so the advantages of carburizing will be lost.

WHAT IS NITRIDING PROCESS?

Nitriding is a chemical heat treatment process in which nitrogen atoms infiltrate the surface of the material in a certain medium at a certain temperature.

All alloy structural steel, tool steel, stainless steel which contains Cr, Mo, V, Ti, Al and other elements can be nitrided.The carbon content of nitriding steel includes the range from low carbon to high carbon.Commonly used nitride steel:EN41B/41CrAlMo7/SACM645.

The purpose of nitriding is to improve the hardness, wear resistance and fatigue life of the material, and to improve the corrosion resistance of the material in the corrosive medium environment.

Can AISI 1045 Steel Be Nitrided?

AISI 1045 steel can be nitrided,but not applicable.As a medium carbon steel without alloying elements,the Fe 4N and Fe 2N nitrides formed after nitriding are relatively unstable, especially if the temperature is slightly higher, it is easy to aggregate and coarsen, so it is impossible to obtain high hardness on the surface.and its core cannot have higher strength and toughness,only a surface permeated layer with certain wear resistance and corrosion resistance can be obtained.

AISI 1045 STEEL VS AISI 5140 STEEL

AISI 1045 and AISI 5140 steel are American standard grades which are widely used in the machinery manufacturing industry.How to choose them correctly to meet our specific requirements is a challenge work we must face. So next we will understand and evaluate their differences from all aspects.

Numbering Designation System

From the AISI/SAE steel designation system,we know that AISI 1045 belongs to 1xxx Group, one of the Carbon steel family,while AISI 5140 belongs to 5xxx Group,one of the Chromium steel family.

Manufacturing Cost

AISI 1045 Vs AISI 5140 Chemical composition comparison

| Grade | C | Si | Mn | P | S | Cr |

| 1045 | 0.43-0.5 | 0.15-0.35 | 0.6-0.9 | ≤ 0.04 | ≤ 0.045 | - |

| 5140 | 0.38-0.43 | 0.15-0.35 | 0.7-0.9 | ≤ 0.035 | ≤ 0.04 | 0.7-0.9 |

From the above table,we can see that the difference in chemical composition is mainly in the content of C and Cr.

In production, Cr in 1045 steel is controlled below 0.3% as a residual element, and Cr in 5140 steel is used as the main alloying element, and the content is between 0.7% and 0.9%.This makes 5140 steel more expensive than 1045 steel in terms of manufacturing costs.When they all meet the demand for use, we will of course give priority to AISI 1045 steel with low economic cost.

Cutting Performance

Generally speaking, although the toughness of materials containing Cr/ Mn increases, the temperature is high during cutting, which is easy to burn the cutter, and the hardening caused by processing is serious.

Although 5140 steel has better toughness, it is worse than 1045 steel in terms of cutting, but the overall performance after quenching and tempering is better than 1045 steel.

Hardenability

The main role of Cr in heat treatment is to improve the hardenability of steel. Due to the increase in hardenability, after quenching and tempering, the mechanical properties of 5140 steel in strength, hardness and impact toughness are also significantly higher than those of 1045 steel.

However,it is also because of the strong hardenability that the internal stress of 5140 steel during quenching is greater than that of 1045 steel. Under the same conditions, the cracking tendency of 5140 steel material is greater than that of 1045 steel material.

Mechanical Properties

Although 5140 steel contains about 1% Cr content, the mechanical properties of 5140 steel and 1045 steel are not much different if they are supplied with hot rolled condition.

However, if after quenching and tempering heat treatment,as we can see from the table below, they have significant differences in strength, toughness,abrasion resistance and impact properties.

| 1045 | 5140 | |

| Tensile Strength | ≥600Mpa | ≥980Mpa |

| Yield Strength | ≥355Mpa | ≥785Mpa |

| Elongation | ≥16% | ≥9% |

| Reduction of Area | ≥40% | ≥45% |

| Impact Charpy-V | ≥39 J | ≥47 J |

| Annealed Hardness | ≤197 HBW | ≤207 HBW |

WHERE TO BUY AISI 1045 STEEL IN CHINA?

While there are a lot of other AISI 1045 steel suppliers in the market, working with us will be the best choice you’ll ever find!

No matter what material it is, you can come to us, and we will do our best to meet your needs

What We Supply For AISI 1045 Steel

| Form of Supply | Size(mm) |

| Round | Φ80-Φ1000 |

| Square | 100 x 100-600x600 |

Flat/Blcoks | Thickness :120-800 |

| Width:120-1500 |

AISI 1045 Hot Forged Flat Steel Bar With Black Surface

What Condition We Supply For AISI 1045 Steel

Heat Treatment

- Normalized(+N)

- Annealed(+A)

- Quenched & Tempered(+QT)

Machining

Turning/Milling/Drilling/Peeling/Polishing

What Size We stock For AISI 1045 Steel

- Hot Rolled Round Bar:Φ20-Φ350mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ250mm,15 days Delivery

- Customized service:Special Size & Length,30 days Delivery

- Free Sample of AISI 1045 Steel

What Advantages We Have

We are Professional Steel Metal Specialist in the steel manufacturing industry. You are most likely in good hands if you deal with a highly reliable manufacturer especially having over 20 years of experience in their craft. It is a huge bonus that we can offer value-added services such as heat treatment, chemical milling, surface machining, and precision grinding.

You can never go wrong with us who has stable quality control of its production processes,remarkable after-sale service,and laudable lead-time & shipment control.

We prefer sustainable relationships with clients rather than short-term profits. In addition, the competence to deliver and promote two-way opportunities for improvement makes us stand out among competitors.