AISI 1018 low carbon steel offers a good balance of toughness, strength and ductility which is the most commonly available grade around the world.Although its mechanical properties are not very unique, it still can be easily formed, machined, welded and fabricated.AISI 1018 steel has excellent weldability and produces a uniform and harder case,and it is considered as the best steel for carburized parts.It may be hardened by carburizing and by other surface-hardening methods.It can attain typical surface hardness to HRC 58 by carburise.

1.AISI 1018 steel Supply Form & Size &Tolerance

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1000 | 3000-10000 |

| Square bar | 100 x 100-600x600 | 3000-6000 |

Flat bar/Blcoks | Thickness :120-800 | 2000-6000 |

| Width:120-1500 |

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition & Related Specifications

| Grade | C | Si | Mn | P | S |

| 1018 | 0.15-0.20 | 0.2-0.4 | 0.60-0.90 | ≤ 0.04 | ≤ 0.05 |

| Germany | UK | China | Japan |

| C15/1.0401 | 080A15 | 15# | S15C |

3. Mechanical Property

| Surface Finish | Tensile Strength Mpa | Yield Strength Mpa | Elongation, % | Hardness,HB |

| Bright Drawn | 430 - 750 | 340 - 600 | ≥ 12 | 120 - 220 |

| Smooth Turned | 410 - 560 | 230 – 330 | ≥22 | 120 - 170 |

4.Forging of AISI 1018 steel

Heat to 1150°C – 1280°C

Hold until uniform

Minimum forging temperature 900°C

Air cooling after forged

5.Heat Treatment

- Normalising: 890–940°C°C,air cooling

- Annealing:870–910°C°C,furnace cooling

- Stress Relieving: 500–700°C,air cooling

- Carburising:880 –920°C

- Core Refining:780–820°C,Quench in water

- Case Hardening:780–820°C,Quench in water

- Carbonitriding:800°C – 875°C,Quench and Temper as required

6.Machinability

The machinability of AISI 1018 is rated at 62% of AISI 1112 carbon steel. Machining provides this material with a fine finish, with continuous and hard chips. It is possible to machine this steel in all conditions

7.Welding

AISI 1018 steel can be instantly welded by all the conventional welding processes,such as gas, oxyacetylene, resistance, and submerged melt welding.But welding is not recommended for this steel when it is carbonitrided and carburized.Low carbon welding electrodes are recommended in the welding procedure, and post-heating and pre-heating are not necessary. Pre-heating can be performed for sections over 50 mm. Post-weld stress relieving also has its own beneficial aspects like the pre-heating process.

8.Application

AISI 1018 is used in bending, crimping and swaging processes,and it is suitably used in applications that do not need high strength of alloy steels and high carbon.AISI 1018 is used to improve drilling, machining, threading and punching processes,and also can be used to prevent cracking in severe bends.

TYPICAL APPLICATIONS:

- Shafts

- Spindles

- Pins

- Rods

- Sprocket assemblies

- Axles,bolts

- Fixtures, mounting plates ,spacers

- Machinery parts

AISI 1018 LOW CARBON STEEL BUYING GUIDE

Different from AISI 1020 and AISI 1045 steel, as a representative of American grades of low-carbon mild steel, there is relatively little basic information about it, and also the products are not common in the market.

This guide will help you sort out and summarize the relevant knowledge of AISI 1018 steel, including manufacturing, heat treatment, and related performance and other aspects.

Reading this guide, in addition to deepening your further understanding of the relevant knowledge in the steel industry, it will also be beneficial to the challenge of how to choose high-quality AISI 1018 steel.

WHAT DOES AISI 1018 MEAN?

We introduced earlier that there are two major institutions in the United States,the American Iron and Steel Institute (A.I.S.I.) and the Society of Automotive Engineers (S.A.E.).They jointly developed and shared a set of steel grade numbering system:Unified Numbering System,referred to as UNS.

When people say AISI 1018 or SAE 1018, they are actually both 1018 steel,and In the UNS,we can find UNS G10180, it is the number for 1018 steel.

For 1018, The first number ‘1’ indicates that the steel is Carbon steel,the second number ‘0’ means that the steel has no main alloy elements,the last two numner’18’ show that this steel has 0.18% carbon.

We can see the main used 101X series carbon grade from ASTM A29 standard as below.

| Grade | C | Mn | P | S |

| 1010 | 0.08-0.13 | 0.30-0.60 | ≤0.04 | ≤0.05 |

| 1015 | 0.13-0.18 | 0.30-0.60 | ≤0.04 | ≤0.05 |

| 1018 | 0.15-0.20 | 0.60-0.90 | ≤0.04 | ≤0.05 |

WHAT IS LOW CARBON STEEL?

Low-carbon steel is carbon steel with a carbon content of less than 0.25%.Because of its low strength, low hardness and softness, it is also called mild steel.

The annealed structure of low carbon steel is ferrite and a small amount of pearlite, which is characterized by low strength and hardness, and good plasticity and toughness.It has good cold formability and can be cold-formed by methods such as crimping, bending, and stamping.

Low-carbon steel includes most ordinary carbon structural steel and some high-quality carbon structural steel. Most of them are used for engineering structural parts without heat treatment, and some are carburized and other heat treated for mechanical parts that require wear resistance, and are often used to make chains. , Rivets, bolts, shafts, etc.

Application of various low carbon steel bolts

AISI 1018 STEEL MAIN CHARACTERISTICS

As a representative of low carbon steel, AISI 1018 and AISI 1020 have similar characteristics in terms of organization, performance, and application. Let’s talk about the main features of AISI 1018 below.

Various Shapes of Supply

AISI 1018 can be manufactured into various shapes such as angle steel, channel steel, I-beam, steel pipe, steel strip or steel plate, round steel, square steel, etc.Customers can find AISI 1018 steel in imperial and metric sizes that meet different requirements for production in various industries.

Good Hot Working Performance

AISI 1018 steel has good hot forming characteristics.On the one hand, it can be deformed by hot rolling and hot forging process through pressure to eliminate casting defects, improve the structure and improve the mechanical properties of materials. On the other hand, it can also be processed as required into various sizes of rings, tubes, shafts, plates and other complex shapes.

Excellent Cold Forming Performance

AISI 1018 annealed structure is ferrite and a small amount of pearlite, its strength and hardness are low, and its plasticity and toughness are better. Therefore, its cold formability is good, and it can be cold-formed by crimping, bending, stamping, cold drawing, etc.

The Future of AISI 1018-Innovation

The use of AISI 1018 low carbon steel is greatly restricted due to its inherent characteristics such as low strength. With the application of some domestic new technologies in the steel industry, many emerging uses of low-carbon steel have been well developed and utilized.

Appropriately increasing the manganese content in carbon steel, and adding trace amounts of alloying elements such as vanadium, titanium, niobium, etc., can greatly increase the strength of the steel.

If the carbon content in the steel is reduced and a small amount of aluminum,boron and carbide forming elements are added, an ultra-low carbon bainite group can be obtained that has high strength and maintains better plasticity and toughness.

IS IT NECESSARY TO CONTROL THE SULFUR AND PHOSPHORUS CONTENT OF AISI 1018 STEEL?

First of all, phosphorus is a harmful element in AISI 1018 steel. It can be completely dissolved in ferrite, which increases the strength of ferrite at room temperature, reduces toughness, produces cold brittleness, and deteriorates cold workability and welding performance of steel. So for phosphorus In general, the lower the better.

For sulfur in AISI 1018 steel, it exists in steel in the form of FeS. FeS and Fe can form a eutectic with a low melting point (985°C). When the processing temperature of thermal processing is higher than this temperature, the eutectic distributed on the grain boundary will melt and cause processing cracks. This is the so-called hot brittleness. Sulfur. The higher the amount, the more severe the hot brittleness.There is a situation that needs to be explained that an appropriate sulfur content can improve the cutting performance of steel grades. This is how free-cutting steel comes from.

Hot cracks in steel

For AISI 1018 steel,from the requirements of ASTM A29 standard, the phosphorus content is controlled below 0.04%, and the sulfur content is controlled below 0.05%. In fact, we should do better to control the P,S content for AISI 1018 steel.

Quality Steel:P≤0.03%,S≤0.03%

High Quality Steel:P≤0.02%,S≤0.02%

Super High Quality Steel:P≤0.02%,S≤0.01%

QUICK FAQS FOR AISI 1018 STEEL

Is AISI 1018 Free-cutting Steel?

Free-cutting steel refers to steel containing a small amount of free-cutting elements, such as sulfur, phosphorus, lead, calcium, selenium, tellurium, etc., which are usually used to improve the cutting performance of materials.

Obviously, AISI 1018 is not free-cutting steel,but it is undeniable that it has advantages in processing, welding, and cold-drawn forming.

AISI 1018 Steel Alternative Grade

As a representative of mild steel, AISI 1018 steel certainly has similar grades internationally.The following table lists the equivalent grades in some countries.It should be noted that they are only the same in elements and similar in composition, and the specific use must comply with the standards of each country.

| Germany | UK | China | Japan |

| C15/1.0401 | 080A15 | 15# | S15C |

Can AISI 1018 Steel be Cold Drawn?

Yes,although the strength of AISI 1018 steel is slightly lower than that of AISI 1020 steel, it has good plasticity and toughness, and good cold drawing properties,so it is very suitable for cold-drawn products.

In actual production, AISI 1018 steel can be cold-drawn out of various high-precision, smooth-surface shapes, such as round steel, square steel, flat steel, hexagonal steel, and irregular shaped steels.

Can AISI 1018 Steel Be Quenched?

AISI 1018 steel is generally used in a normalized condition which is used to manufacture various mechanical parts that are not stressed but require high toughness.

AISI 1018 steel is low-carbon steel without alloys, only 0.18% carbon content. It is difficult to quench, and it is not common to use it directly after quenching.

Can AISI 1018 Steel Be Carburized?

AISI 1018 steel is low carbon steel, which is very suitable for carburizing process.

AISI 1018 steel is generally quenching and low temperature tempering after carburizing.The carburized AISI 1018 steel has high surface hardness, good wear resistance, and good core toughness. It is suitable for manufacturing wear-resistant parts subject to small impact loads, such as small shafts, pinions, piston pins, etc.

What is Hardness of AISI 1018 Steel?

AISI 1018 steel is supplied with normalized condition or without heat treatment,and its hardness is generally between 120-150HB.

If higher hardness is required, AISI 1018 steel needs to be carburized. After carburizing and quenching, the surface hardness can reach 56HRC or more, and the core hardness is less than 30HRC.

DIFFERENCE:AISI 1018 STEEL Vs S355J2G3 STEEL

First of all, AISI 1018 is an American grade, a kind of low-carbon steel, derived from ASTM A29 standard, while S355J2G3 is a European grade, belonging to low-carbon structural steel, derived from EN10250-2 standard.Next, let’s take a look at the main differences between them.

- Chemical Composition

| Grade | C | Si | Mn | P | S |

| AISI 1018 | 0.15-0.20 | 0.10-0.35 | 0.60-0.90 | ≤0.04 | ≤0.05 |

| S355J2G3 | ≤ 0.22 | ≤0.55 | ≤1.6 | ≤ 0.035 | ≤ 0.035 |

| For S355J2G3 | Cr≤0.3,Mo≤0.08,Ni≤0.3,Cr+Mo+Ni≤0.48,Al≥0.02 | ||||

From the above table, it can be seen that there is not much difference between the two materials. The composition adjustment of S355J2G3 is more flexible, but the control of residual metal elements is stricter.

- Supply Condition

AISI 1018 and S355J2G3 are generally supplied under normalizing conditions. The difference is that S355J2G3 must be normalized, while AISI 1018 does not have this requirement.

- Mechanical Property

The tensile strength of the two materials under normalizing conditions is not much different, generally between 400-600Mpa.The average yield strength of S355J2G3 is around 355Mpa, which is the origin of S355.

The biggest difference is that S355J2G3 has strict requirements for low-temperature impact, that is, it must meet the requirement that the impact of minus 20 degrees is not less than 27J.However, AISI 1018 does not have this requirement.

HOW TO NORMALIZING AISI 1018 STEEL?

For low carbon steel, the first consideration is not how to improve its strength, but should consider how to improve its toughness.

For AISI 1018 steel, normalizing is quite applicable,it can be used as a final heat treatment or as a preliminary heat treatment to prepare for the further treatment of the material, such as the carburizing process.Next we will talk about the normalizing heat treatment of AISI 1018 steel.

AISI 1018 Plates Normalizing

Temperature & Holding Time

Generally, the normalizing temperature of low carbon steel is generally heated to Ac3+ (30-50℃),for AISI 1018,it should be 900-940℃.In the heating stage, if the size of AISI 1018 workpiece is small, it can be uniformly heated to the normalizing temperature at one time for heat preservation.

However, if the size of the workpiece is large in cross section, it is necessary to consider heating in stages, such as heating to 450°C for 1 hour, then heat again to 650°C with keeping for 1 hour again, finally heat to normalizing temperature,then hold temperature. The purpose of this is to ensure that the workpiece is completely heated and heated evenly.

It should be noted that too high temperature and too long holding time are not beneficial to AISI 1018 steel. It will coarsen austenite and cause a significant decrease in mechanical properties.

Cooling Method

Normalizing does not need to be cooled with the furnace like annealing, so the furnace takes up a short time and the production efficiency is high.The cooling rate of normalizing is faster than annealing. Due to the high degree of undercooling, the pearlite grains obtained are thinner, the carbides are distributed evenly, and the material structure is more balanced.

Considering the cooling rate, water spray cooling> water mist cooling> air blowing cooling.The hardness of AISI 1018 steel after spraying water will be relatively higher, and the toughness is also better, which is convenient for cutting and processing.

AISI 1018 STEEL APPLICATIONS

AISI 1018 steel is a low-carbon steel. In actual use, there are two completely different application methods according to its own characteristics.

In the first case, according to the inherent characteristics of AISI 1018 steel: low strength but good toughness and plasticity.

Under hot-rolled or normalized conditions,AISI 1018 steel can be used to manufacture various mechanical parts that are not stressed but require high toughness,unimportant structural parts, connecting parts and stamping parts.

In the second case, according to the low-carbon composition characteristics of AISI 1018 steel, carburizing process can be selected to obtain a high-strength surface and a core with good toughness.It is suitable for manufacturing small and medium-sized parts in automobiles and tractors,And small and medium-sized parts that are not important for construction in general machinery manufacturing,such as handbrake shoes, lever shafts, gearbox speed forks, transmission passive gears and camshafts on tractors, suspension equalizer shafts, equalizer inner and outer bushings on automobiles, etc.

Auto Parts-Crankshaft

HOW DO WE MANUFACTURE HIGH-QUALITY AISI 1018 STEEL?

As a special steel manufacturer and supplier with more than ten years of manufacturing experience, no one knows AISI 1018 steel better than us.Here, we can confidently tell you everything you want to know about AISI 1018.Next, we will probably talk about how we produce high-quality AISI1018 steel.

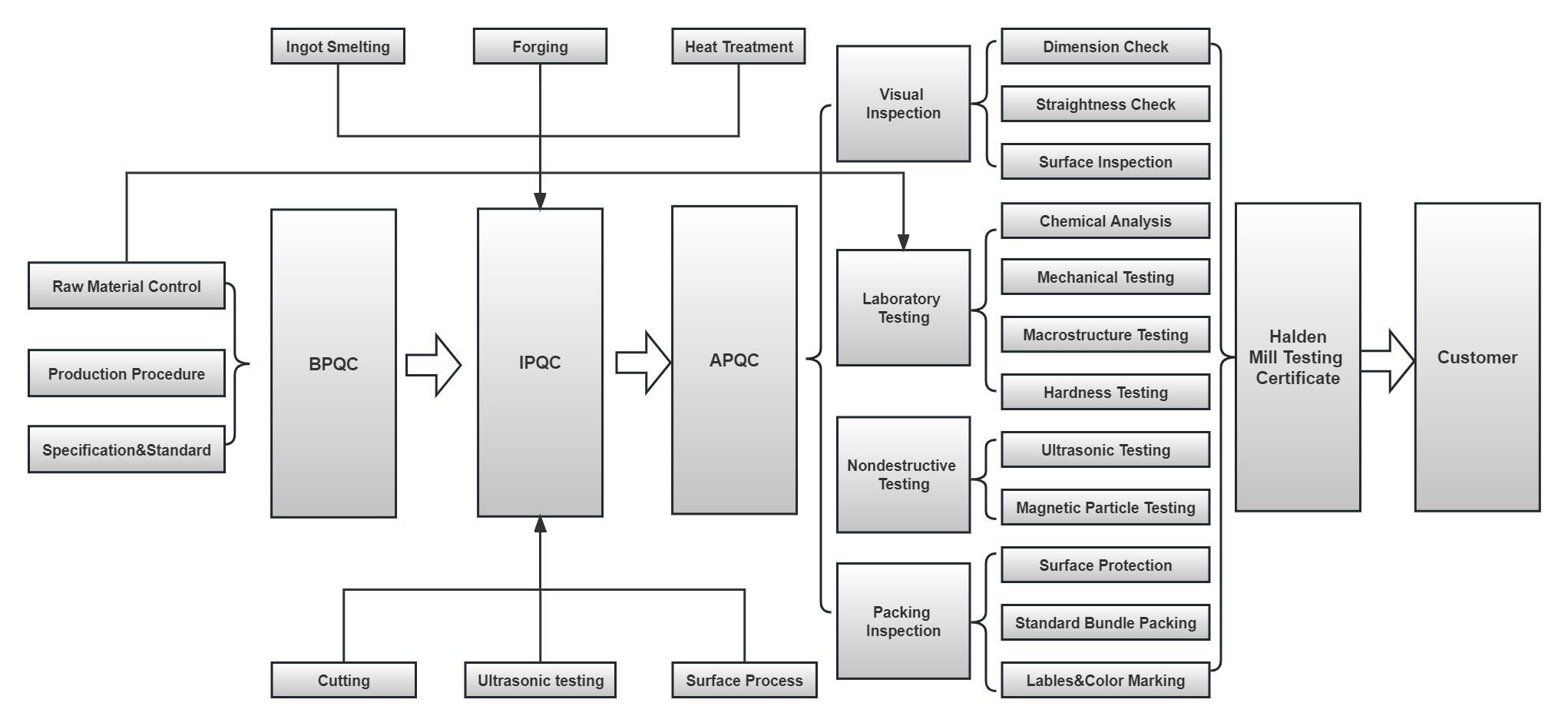

From the beginning of the raw materials to the final product, we strictly control each step of the process in accordance with the requirements of the quality system,and we generally carry out three procedures on quality control as below

- Before Production Quality Control(BPQC)

Before production, we have done a lot of preparatory work, including raw material control, technical standard research and production process optimization.

- In Production Quality Control(IPQC)

According to production procedure,IPQC are carried out to ensure production can meet the designated technical requirements.Do necessary tests during the production. Inspection hold point will be carried out during Smelting,Foring,Heat Treatment and Machining process to check whether the procedure is under control properly.

- After Production Quality Control(APQC)

After the production of products,we will carry out quality inspection for final products.Testing results for each testing will be recorded to ensure that all products meet customer requirements.

Quality Control Procedure

WHAT WE SUPPLY FOR AISI 1018 STEEL?

| Form of Supply | Size(mm) |

| Round | Φ80-Φ1000 |

| Square | 100 x 100-600x600 |

Flat/Blcoks | Thickness :120-800 |

| Width:120-1500 |

Supply Condition:Normalized(+N),Annealed(+A), Hot Forged.