As two low-alloy structural steel grades under BS970 British Standard, EN19 and EN24 are widely used in various industries due to their excellent comprehensive properties.

In the previous article, we compared 4140 vs 4340 under the American standard, and 42CrMo4 vs 34CrNiMo6 under the European standard.Then, as an equivalent grade,what is the difference between EN19 and EN24?Next, we will discuss it in detail.

1.Chemical Composition

EN19 and EN24 steel are both derived from the British standard BS970-1955.At that time, the British Standardization Institute (BSI) simply defined special steel as ENXX, where XX only represented numbers without rules. Therefore, the EN19 and EN24 here have no practical meaning literally.Then look at the actual chemical composition in detail.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN24 | 0.35-0.45 | 0.10-0.35 | 0.45-0.7 | ≤0.05 | ≤0.05 | 0.9-1.4 | 1.3-1.8 | 0.2-0.35 |

| EN19 | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.5 | - | 0.2-0.4 |

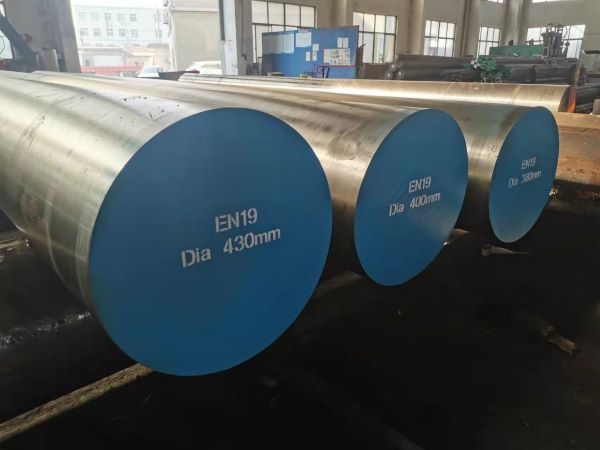

As can be seen from the table above, the main composition difference between EN19 and EN24 is that EN24 contains 1.5% nickel, while EN19 does not.In addition, due to the difference in 1.5% Ni element, the manufacturing cost of EN24 steel is significantly higher than that of EN19 steel.

2.Hardenability

The hardenability of steel mainly depends on its chemical composition, of which carbon plays a decisive role, while alloy elements such as Cr, Ni, Mo, Mn, V, Ti, etc. can also further improve its hardenability.Here we can clearly conclude that the hardenability of EN24 steel is better than that of EN19 steel.

3.Weldability

Considering the same content of other elements, EN24 contains an excess of 1.5% Ni element. According to the carbon equivalent calculation formula CE=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 recommended by the International Institute of Welding (IIW),based on comprehensive calculation, the CE value of EN24 must be about 0.1 more than that of EN19.This means that the weldability of EN24 is relatively worse than that of EN19 steel.

However, we also have to know that EN19 and EN24 steel are difficult to weld materials, and their CE values are greater than 0.5, which means that the weldability is poor.

4.Strength & Hardness

For hardened and tempered materials,the varying tensile ranges for the different specifications have been designated with the letters P to Z so that the same letters always represent the same tensile range and corresponding hardness range. The symbols are as follows:

| Symbol | Tensile,Mpa | Corresponding Hardness,HBW |

| P | 550-700 | 152-207 |

| Q | 625-775 | 179-229 |

| R | 700-850 | 201-255 |

| S | 775-925 | 223-277 |

| T | 850-1000 | 248-302 |

| U | 925-1075 | 269-321 |

| V | 1000-1150 | 293-341 |

| W | 1075-1225 | 311-375 |

| X | 1150-1300 | 341-388 |

| Y | 1225-1375 | 363-415 |

| Z | ≥1500 | ≥444 |

For EN19 steel, it is suitable for condition R, S, T, U, V, W, Y. Among them, T is the most commonly used, which is EN19T.For EN24 steel, it is suitable for condition S, T, U, V, W, X, Y, Z. Among them, T and U are the most commonly used ones, namely EN24T and EN24U.

But generally speaking, under the same conditionT, compared with EN19 steel, EN24 steel is more suitable for heavy machinery parts or under extreme conditions that require higher strength and toughness

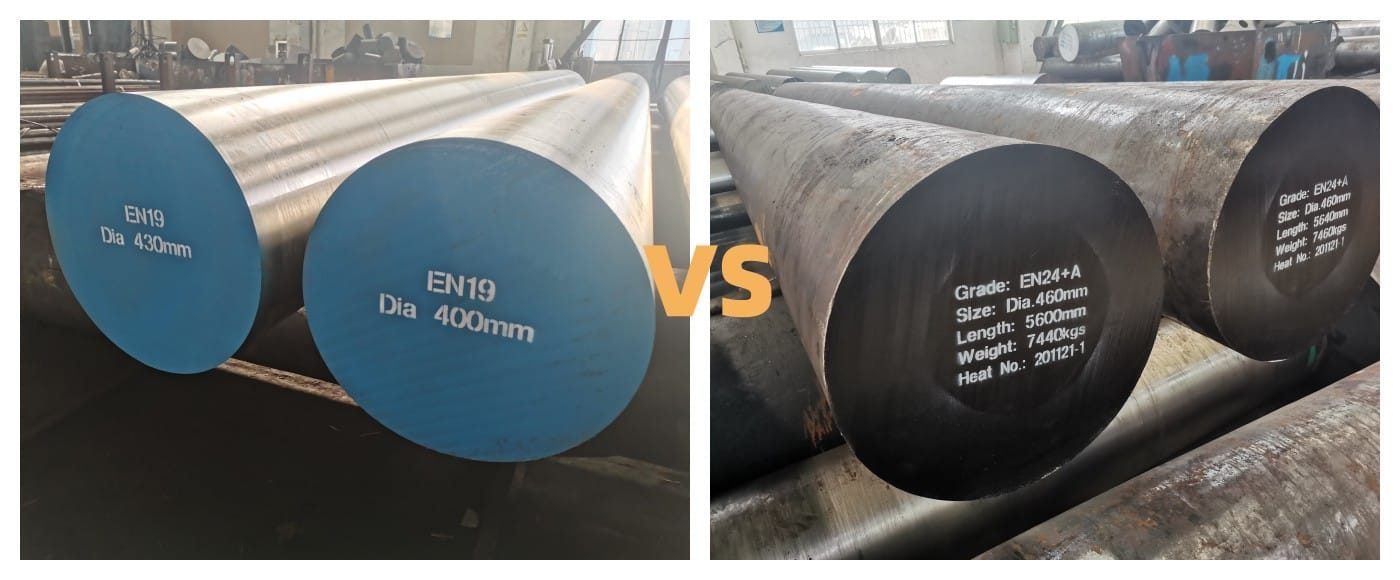

As a stockist of high-quality steel EN19 steel and EN24 steel, we are willing to provide customers with high-quality products and services. If you have this demand, please feel free to contact us.