EN24 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.EN24/817M40, ‘1.5% Nickel-Chromium-Molybdenum’ alloy steel, has a good combination of strength, ductility, low temperature impact, wear resistance and good machinability.This steel is usually supplied in annealed condition after forged,and also suitable for hardened and tempered condition with tensile ranges of S(775-925Mpa),T(850-1000Mpa),U(925-1080Mpa),V(1000-1160Mpa),W(1080-1235Mpa),X(1160-1320Mpa),Y(1235-1390Mpa),and Z(1545Mpa). For further process,it can be surface-hardened typically to 58-60 HRC by induction or nitride processes, producing components with enhanced wear resistance.

1.Supply Form & Size & Tolerance

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ280mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN24 | 0.35-0.45 | 0.10-0.35 | 0.45-0.7 | ≤0.05 | ≤0.05 | 0.9-1.4 | 1.3-1.8 | 0.2-0.35 |

| 817M40 | 0.36-0.44 | 0.1-0.4 | 0.45-0.7 | ≤0.035 | ≤0.04 | 1.0-1.4 | 1.3-1.7 | 0.2-0.35 |

3. Equivalent Grade

ASTM:4340

EN/DIN:34CrNiMo6/DIN 1.6582

JIS:SNCM449

GB:40CrNiMo

4. Mechanical Property

Condition | Hardened & Tempered |

|||||||

| S | T | U | V | W | X | Y | Z | |

| Ruling Section,inch | 6 | 6 | 4 | 2 1/2 | 1 1/8 | 1 1/8 | 1 1/8 | 1 1/8 |

| Tensile Strength,Mpa,Min | 775 | 850 | 925 | 1000 | 1080 | 1160 | 1235 | 1545 |

| Yield Strength,Mpa,Min | 585 | 680 | 740 | 800 | 895 | 970 | 1050 | 1310 |

| Elongation,Min | 20 | 18 | 17 | 16 | 15 | 14 | 14 | 8 |

| ISO V Impact,J,Min | 54 | 54 | 48 | 48 | 40 | 34 | 30 | 11 |

| Hardness,HBW | 223-277 | 248-302 | 269-321 | 293-341 | 311-375 | 341-388 | 363-415 | ≥444 |

0.2% Proof Stress tests value with Quenched & Tempered condition

| Property | S | T | U | V | W | X | Y | Z |

| Proof Stress(0.2%) Mpa,Min | 555 | 635 | 710 | 775 | 850 | 910 | 990 | 1235 |

EN24 Round steel Lab Tesing Data with Quenched & Tempered condition

| Diameter,mm | Tensile Strength MPa | Yield Strength MPa | Elongation % | Reduction % | Impact,J | Hardness,HB |

| Φ420 | 960 | 790 | 15 | 42.5 | 76/52/50 | 291 |

| Φ430 | 960 | 795 | 14 | 48.5 | 86/68/68 | 299 |

| Φ450 | 940 | 750 | 18 | 50 | 95/90/110 | 302 |

5.Forging EN24/817M40 Steel

Recommended Forging temperature:850℃- 1150℃,and final forging temperature should not below 850℃.Cooling as slowly as possible in the furnace to prevent surface crack,and annealing immediately after forged is recommended.

6.Heat Treatment

- Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.Normalizing temperature for EN24 steel should be carried out between 850℃-880℃ with several steps,keep proper holding time depend on the steel size for the steel to be thoroughly heated to complete the ferrite to austenite transformation.Cool in still air.

- Annealing

Annealing is generally applied after forged and before machining to reduce surface harness,and get finer grain,get good machinability.

Soft Annealing:Heat the steel to the temperaure 650℃-680℃,Holding temperature for the steel heating, Cool slowly in the furnace.

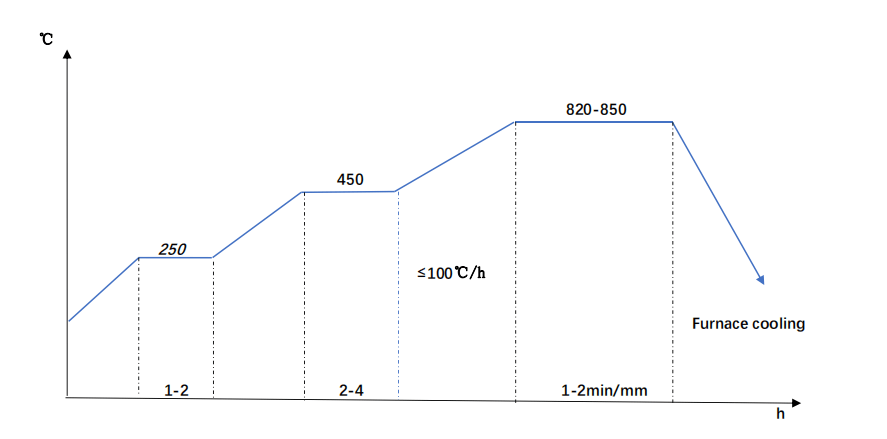

Full Annealing:Heat the steel to the temperaure 820-850℃ with three steps ,Holding temperature for the steel heating,Cool in furnace.Surface hardness after annealing will be below 248HB.

EN24/817M40 Annealing Diagram

- Hardening

Hardening temperature is carried out from an austenitizing temperature of 820-850ºC with several steps,keep suitable time for the steel to be thoroughly heated, oil quenching is recommended.

- Tempering

Tempering process should be followed after quenching immediately.Tempering at a suitable temperature not exceeding 660ºC .

7.Application

EN24/817M40 steel is widely used as engineering steel in Automobile Industry, Construction, Pharmaceutical / Chemical Industry, Oil & Gas Industry.It is often utilized where other alloy steels do not have the hardenability to give the strength required. For highly stressed parts it is also an excellent choice.

Typical Applications:

- Heavy-duty axles & Shafts

- Punches & Dies

- Studs & Bolts

- Gears & Rings

EN24/817M40 STEEL BUYING GUIDE

First of all, what we want to tell you is that the steel grade EN24 is one of the most commonly used Cr-Ni-Mo series low alloy steels in the UK, and its role is similar to 4340 in the United States and 34CrNiMo6 in Europe.

Secondly, on how to choose EN24 steel, this is what we will do next.

From our guide, we will sort out all the knowledge information related to EN24/817M40 steel,and obtain a good accumulation of knowledge, which will further help us choose high-quality EN24 steel.

WHAT IS EN24/817M40 STEEL?

After traceability, we know that EN24 comes from standard BS970-1955, and 817M40 comes from standard BS970-1991. It can be said that 817M40 is an upgraded version of EN24. So the question is, what is the meaning of the numbers and letters in their grades?

In the past, the British Standardization Institute (BSI) simply defined carbon steel, alloy steel, and stainless steel as ENXX,And XX just represents a number without giving it any specific meaning.In other words, EN24 is just a code name and does not describe its characteristics.

With the continuous emergence of new steel grades,this simple representation is unable to meet the needs.Considering these shortcomings, BSI has released a new numerical steel number system to replace the previous representation.Therefore, corresponding to EN24, 817M40 is the new steel grade code.

Next, we will briefly introduce the new digital steel grade system as below

OOO X OO

The first O represents a number, indicating the steel type.For specific meaning, see table 1

The second and third OO represent numbers, indicating the chemical composition of the characteristic or the serial number of the steel group.For specific meaning, see table 2

X stands for letter, indicating supply condition or material type

- A: The first letter of Analyse, indicating that the supply conditions are guaranteed chemical composition.

- M: The first letter of Mechanical, indicating that the supply conditions are guaranteed mechanical properties.

- H: The first letter of Hardenability, indicating that the supply condition is to ensure hardenability.

- S: The first letter of Stainless, which means stainless steel.

The last two OO, representing numbers, indicate the average carbon content.

| Table 1 | ||||

| 0 | 1 | 2 | 3 | 4 |

| Carbon steel | Stainless steel | |||

| Ordinary manganese steel | High manganese steel | Free cutting steel | Austenitic steel | Martensitic & Ferritic steel |

| Table 2 | |||

| 50 | Ni steel | 78 | MnNiMo steel |

| 52 | Cr steel,w(Cr)<1% | 80 | NiCrMo steel,w(Ni)<1% |

| 53 | Cr steel,w(Cr)≥1% | 81 | NiCrMo steel,w(Ni):1-1.5% |

| 60 | MnMo steel | 82 | NiCrMo steel,w(Ni):1.5-3% |

| 63 | NiCr steel,w(Ni)<1% | 83 | NiCrMo steel,w(Ni):3-4.5% |

| 64 | NiCr steel,w(Ni):1.1-2.5% | 87 | CrNiMo steel,w(Cr)>1% |

| 65 | NiCr steel,w(Ni):2.5-4.5% | 89 | CrMoV steel |

| 66 | NiMo steel | 90 | CrMoAl steel |

| 70 | CrMo steel,w(Cr)<1.1% | 92 | SiMnMo steel |

| 72 | CrMo steel,w(Cr)≥3% | 94 | MnNiCrMo steel |

| 73 | CrV steel | ||

From the above content, 817M40 is expressed as a NiCrMo alloy steel with a Ni content of about 1.0-1.5% and an average carbon content of 0.4%, and this steel guarantees the mechanical properties of the material.

IS EN24 STEEL SAME AS 4340 STEEL?

First of all, EN24 and 4340 steels belong to the Cr-Ni-Mo series of low-alloy high-strength steels. As international equivalent steel grades, EN24 steels come from the BS970 standard in the UK, while 4340 comes from the ASTM A29 standard in the United States.Although the standards are different, they have excellent comprehensive performance and are widely used in various industries.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN24 | 0.35-0.45 | 0.10-0.35 | 0.45-0.7 | ≤0.05 | ≤0.05 | 0.9-1.4 | 1.3-1.8 | 0.2-0.35 |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | ≤0.035 | ≤0.04 | 0.7-0.9 | 1.65-2.0 | 0.2-0.3 |

In terms of chemical composition, we can see from the above table that EN24 and 4340 have certain differences in Mn, Cr, and Ni elements, but this does not affect their high strength, high hardness and good hardenability.

Although 4340 steel is stricter than EN24 in terms of the control standards for P and S harmful elements, in actual production, all efforts are made to reduce the influence of harmful elements, which is higher than the standard.

There is little difference between EN24 and 4340 steel in terms of manufacturing, heat treatment, processing and application.Sometimes when the requirements are not strict, it can be used as an approximate substitute to meet the actual application requirements.

QUICK FAQS FOR EN24/817M40 STEEL

What is EN24T Steel?

In brief,EN24T means that the tensile strength of EN24 in the quenched and tempered state should reach 850-1000Mpa.

So, how did this T come from?

In the BS970 standard, the different tensile strengths in the quenched and tempered state are expressed as different letters, which are 11 groups from P to Z, and the tensile strength spans from 550-1500Mpa as shown in the following table.

| Symbol | Tensile,Mpa | Symbol | Tensile,Mpa |

| P | 550-700 | V | 1000-1150 |

| Q | 625-775 | W | 1075-1225 |

| R | 700-850 | X | 1150-1300 |

| S | 775-925 | Y | 1225-1375 |

| T | 850-1000 | Z | 1500 Min |

| U | 925-1075 |

What is the hardness of EN24 Steel?

EN24 steel without heat treatment has no specific mechanical or application values.

Generally speaking, the hardness obtained after EN24 annealing is lower than 217HBW,which is favorable for turning.

If EN24 needs to obtain good hardness, it can be achieved by quenching and tempering heat treatment.In fact, according to the standard of BS970, EN24 obtains satisfactory hardness value through tempering and tempering. The specific table is as follows

Condition | Hardened & Tempered |

|||||||

| S | T | U | V | W | X | Y | Z | |

| Tensile Strength,Mpa,Min | 775 | 850 | 925 | 1000 | 1080 | 1160 | 1235 | 1545 |

| Hardness,HBW | 223-277 | 248-302 | 269-321 | 293-341 | 311-375 | 341-388 | 363-415 | ≥444 |

In addition, EN24 steel can be nitrided to obtain high hardness.After nitriding, the surface hardness of EN24 steel can reach 600-800HV, and the nitration hardness depth is 0.1-0.6mm.

Is EN24 Steel hard to forge?

EN24 steel is characterized by high strength, good plasticity and toughness. Compared with medium and low carbon steel, it is a little difficult to forge EN24 steel,however, a reasonable forging process can ensure that the billet is heated evenly and fully, and the material is uniformly deformed, so that the properties of the material are consistent everywhere.

Due to the high sensitivity of EN24 steel to white spots and cracks, post-forging annealing treatment is particularly important, which can effectively prevent the occurrence of the above-mentioned defects.

Is EN24 steel easy to machine?

First of all, EN24 steel is annealed after forging, and its hardness is usually lower than 229HBW, which is still very easy to process.

If the quenched and tempered hardness is controlled at about 300HBW, EN24 steel is still slightly more difficult to process than EN19. If the required application hardness is extremely high, it needs to be processed by matching tools, such as CBN tools and PCD tools.

What is EN24 steel used for?

As a 1.5% Cr-Ni-Mo alloy structural steel, EN24 steel has high strength, good ductility and wear resistance, and good low temperature impact toughness after quenching and tempering.

Due to the above excellent characteristics, EN24 steel has been widely used in machinery manufacturing, automobile industry, aviation industry, and chemical industry.It is often used to manufacture gears, shafts, crankshafts, rollers, etc,and is also particularly suitable for making punches, dies and drilling bushings.

WHAT IS THE DIFFERENCE BETWEEN EN24 AND EN19 STEEL?

EN19 and EN24 belong to the EN series of alloy structural steels, both of which are heat-treated steels.Talking about their differences, they are a bit similar to American Standard’s 4340 and 4140 steels. Let’s take a brief look at them below.

- Different steel grade series

As alloy structural steel, EN19 belongs to Cr-Mo series, while EN24 belongs to Cr-Ni-Mo series.As an alloy structural steel, EN19 belongs to the Cr-Mo series, while EN24 belongs to the Cr-Ni-Mo series. Compared with EN19, which does not contain Ni, EN24 contains 1.5% of Ni.For details, please see the chemical composition comparison table below.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN24 | 0.35-0.45 | 0.10-0.35 | 0.45-0.7 | ≤0.05 | ≤0.05 | 0.9-1.4 | 1.3-1.8 | 0.2-0.35 |

| EN19 | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.5 | - | 0.2-0.4 |

- Dfferent production costs

Since EN24 steel has 1.5% Ni element, and the rest elements have little difference with EN19, the production cost of EN24 steel is significantly higher than that of EN19 steel. When they can meet the application requirements, we should give priority to the cost-effective EN19 steel.

- Hardenability difference

The hardenability of the material is mainly affected by carbon elements. In addition, it is also affected by alloying elements. The alloying elements that improve the hardenability are Cr, Ni, Mo, Mn, V, Ti, etc. It can be seen that EN24 The hardenability of steel is significantly better than that of EN19 steel.

- Difficulty of weldability

Both EN24 and EN19 steels are relatively difficult materials to weld, and EN19 is relatively easy to weld.

For the welding of these two materials, in order to ensure high welding quality, strict welding process control is necessary, such as preheating before welding, and stress relief heat treatment after welding.

In addition to the above points, EN19 and EN24 steels also have obvious differences in heat treatment, mechanical properties, industrial applications, etc. When we consider choosing them, we must comprehensively consider and make the best choice.

HOW TO QUENCHING AND TEMPERING EN24 STEEL?

As a heat-treated low-alloy steel, In the actual production process,EN24 steel is usually delivered in a heat-treated condition, the typical heat treatment of this steel involves two stages,that is quenching and tempering.

EN24 steel can obtain high strength and hardness after quenching to a full martensitic microstructure,while the ductility and toughness can be improved with tempering.More over,it exhibits very good toughness properties with a Charpy V-notch at a very low tem- perature.

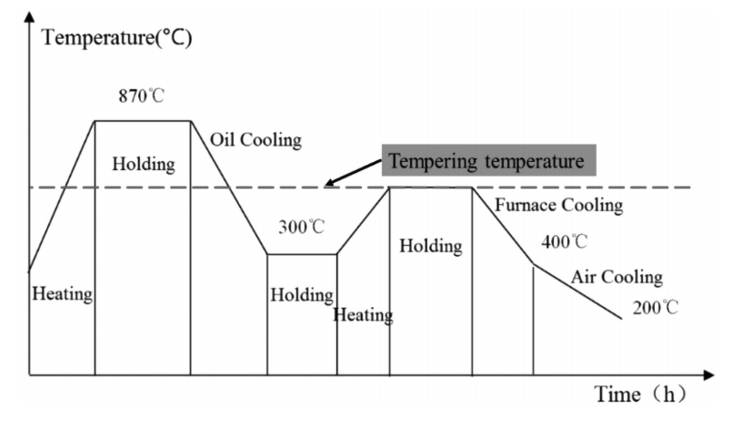

EN24 Steel Q&T Process Details

- Quenching Temperature:850-880ºC

- Quenching Medium: Oil

- TemperingTemperature:570-690ºC

- Cooling Medium:Furnace cooling to 400ºC,then air cooling to below 200ºC

The specific process is shown in the figure below

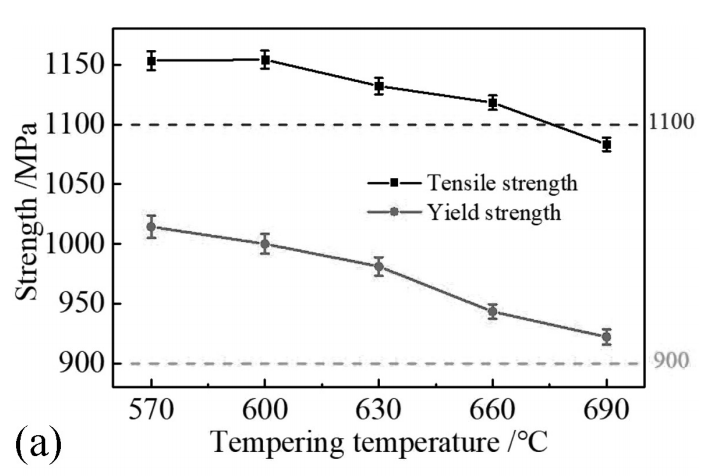

EN24 Steel Mechanical Properties Diagram in Quenched and Tempered condition

EN24 Steel Strength vs Tempering Temperature Diagram

EN24 Steel Elongation vs Tempering Temperature Diagram

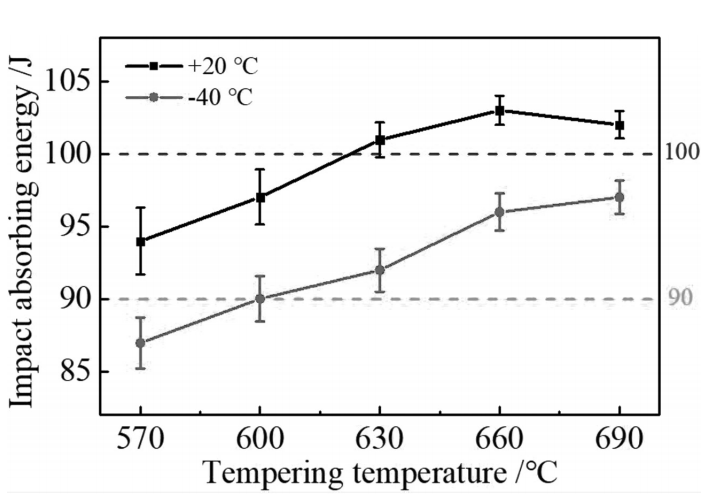

EN24 Steel Impact vs Tempering Temperature Diagram

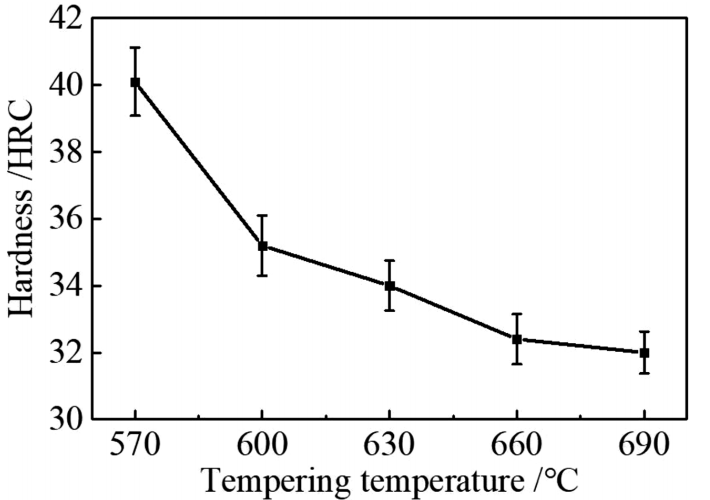

EN24 Steel Hardness vs Tempering Temperature Diagram

From the above diagrams, the following conclusions can be summarized.

- Both the tensile strength and yield strength decrease with the increasing tempering temperature.

- In contrast, the elongation after breakage increases with the increasing tempering temperature up to 660ºC, while remaining almost stable from 660ºC to 690ºC.

- The Rockwell hardness C decreases with the increasing tem- pering temperature up to 660 °C, while remaining almost stable from 660ºC to 690°C.

- The impact-absorbing energy increases with the increasing tempering temperature and then decreases between 660°C and 690°C when the testing temperature is 20°C. The impact-absorbing energy increases monotonously with the increasing tempering temperature when the testing temperature is -40°C.

BUYING EN24/817M40 STEEL: WHICH SUPPLIER SHOULD YOU WORK WITH?

For the manufacture of Cr-Ni-Mo series alloy steel such as EN24, it is still a test of the ability of a manufacturer.How to manufacture is only the first step, how to further manufacture high-quality EN24 steel stumped a large number of manufacturers.

With more than 15 years of rich manufacturing experience, we can not only manufacture high-quality special steel, but also provide complete one-stop processing and after-sales service,including heat treatment,machining and cutting.We strive to make ourselves excellent, always insist on growing together with our customers, and become a loyal strategic partner of our customers.

What We Supply For EN24/817M40 Steel

Hot Rolled Round bars

- Dia 14-350mm daily stock wih 2000+tons round bars

- Annealed/Q&T(pre hardened)condition for 5 days delivery available

- Bright steel with QT condition for 10 days delivery available

- Cut to length service available

Hot Forged bars

- Daily stock ingots to meet customer urgent order needs

- Dia 80-1000mm full size forging available

- Square/Flat/Blocks/Shafts customized production

- Conventional heat treatment service

- One-stop machining service