When it comes to hot work tool steel, American Standard H13 steel is what flashes through our minds, which is indeed too popular.Similarly, SKD61 steel, a hot work tool steel belonging to the Japanese standard, is also quite practical in the Southeast Asian market.

Therefore, as a typical representative of hot work tool steel, where are their similarities and differences? Next, we will discuss in detail.

1.Chemical Composition

To see the essence through the phenomenon, first of all, we analyze from the most basic chemical composition.

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo | V |

| ASTM A681 | H13 | 0.32-0.45 | 0.8-1.2 | 0.20-0.50 | ≤0.03 | ≤0.03 | 4.75-5.50 | 1.1-1.75 | 0.8-1.2 |

| JIS G4404 | SKD61 | 0.35-0.42 | 0.8-1.2 | 0.25-0.5 | ≤0.03 | ≤0.02 | 4.8-5.5 | 1.0-1.5 | 0.8-1.15 |

From the above table, we can clearly feel that there is basically no obvious difference in chemical composition between H13 and SKD61, only minor adjustments of individual elements. Considering that in actual production, the chemical composition is smelted and controlled much higher than the lower limit, these slight differences can be ignored.Therefore, in similar applications, we can consider equivalent substitutions.

2.Delivery Status

Whether H13 steel and SKD61 steel are forged or hot-rolled, they are generally delivered in an annealed condition.

| Grade | Annealing | |

| Temperature | Hardness | |

| H13 | 845-900°C | ≤235HBW |

| SKD61 | 820-870°C | ≤229HBW |

According to our experience, after actual annealing, their hardness is usually lower than 200HBW, which meet the supply requirements.

3.Heat Treatment

As hot work tool steels, H13 and SKD61 need to work under high temperature and high pressure, which requires them to have excellent performance.As the most important process in heat treatment, quenching and tempering can greatly increase the hardness and strength of H13 and SKD61, and improve the useful life of the material.

| Grade | Quenching | Tempering |

| H13 | 1000-1050°C | 550°C |

| SKD61 | 990-1040°C | 590°C |

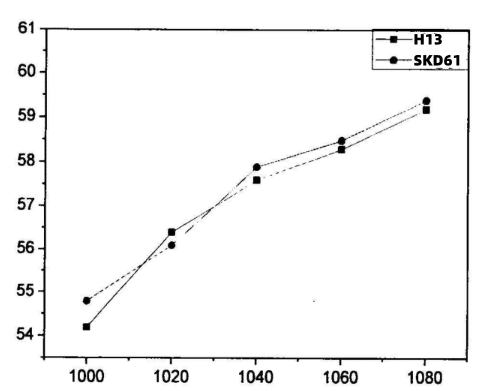

Quenching Temperature vs Hardness For H13 and SKD61

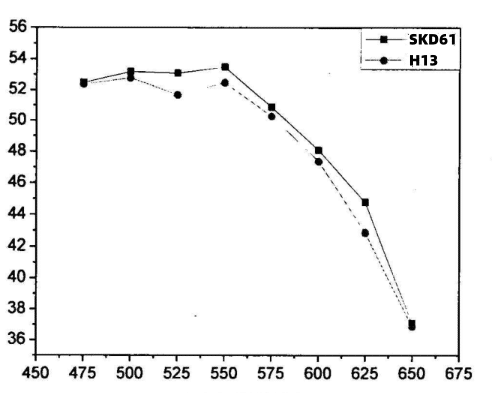

Tempering Temperature vs Hardness For H13 and SKD61

From the above relationship diagram, we can see that the hardness of H13 steel and SKD61 steel increases with the increase of quenching temperature, and decreases with the increase of tempering temperature.When the tempering temperature is higher than 600°C, its hardness will drop sharply, which is why the service temperature of H13 and SKD61 steel is usually below 550°C.

At the same time, we can also find that the tempering stability of SKD61 steel is better than that of H13 steel, and its hardness is higher than that of H13 steel at each tempering temperature.

Although H13 steel and SKD61 steel have different differences, this does not affect their wide application in the field of hot work steel.As an excellent tool steel supplier, we are willing to provide you with high-quality SKD61 and H13 steel.If you have any needs in this area, please do not hesitate to contact us.