H13 Steel is defined as Cr-Mo-Si-V tool Steel as per American standard ASTM A681.

As the most widely used and most representative hot-work die steel, H13 steel has high toughness, cold and hot fatigue resistance and high thermal strength when the temperature is less than 600℃.

As a hot working die steel with both strength and toughness, H13 steel is not easy to produce thermal fatigue cracks and has a relatively high service life when used as a hot extrusion die. It is also commonly used to manufacture forging dies with large impact load, copper aluminum alloy die-casting dies, high-speed precision forging dies and forging press dies.

H13 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

H13 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | V |

| H13 | 0.32-0.45 | 0.8-1.25 | 0.20-0.60 | ≤ 0.03 | ≤ 0.03 | 4.75-5.50 | 1.1-1.75 | 0.8-1.2 |

H13 STEEL RELATED STANDARD & EQUIVALENT GRADE

China/GB 1299: 4Cr5MoSiV1

Germany/DIN 17350: 1.2344

Japan/JIS G4404: SKD61

H13 STEEL FORGING

The forging process performance of H13 steel is very poor. Because it is hard and brittle, if the forging process is not arranged properly, it is easy to produce cracks during forging and lead to scrap.

The forging temperature range of H13 steel is very narrow, only 150~200℃, so we must strictly control its forging temperature.

- Initial Forging Temperature:1065-1175℃

- Final Forging Temperature:850-900℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:H13 steel needs to be annealed after forging.After heating to 860 ℃ for heat preservation,cool slowly, the cooling rate is about 30 ℃/h,and after cooling to 400~500°C in the furnace, air cooling.

H13 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of H13 Steel

- Ac1:875℃

- Ac3:935℃

- Ar1:760℃

- Ms:305℃

H13 Steel Annealing

H13 steel belongs to hypereutectoid steel, and the commonly used annealing processes are complete annealing, isothermal spheroidizing annealing and stress relief annealing.

- H13 Steel Complete Annealing

The full annealing temperature of H13 steel is 845-900℃,and the holding time is 3-4 hours,and then furnace cooled to 500℃ with the rate 22℃/h max.Annealed hardness is usually 192-229HBW

- H13 Steel Isothermal Spheroidizing Annealing

The isothermal spheroidizing annealing temperature of H13 steel is 845-900 ℃, which is kept for 2-4 hours and then cooled to 700-740 ℃ with the furnace, and kept for 3-4 hours.Finally cooling to below 500°C in the furnace and then air-cooling.

- H13 Steel Stress Relief Annealing.

For parts with complex shape and structure, H13 steel needs to undergo stress relief annealing.The temperature is controlled at 730-760 ° C, and it is cooled in the furnace after holding for 2 hours.

H13 Steel Quenching & Tempering

H13 Steel Quenching Details:

- Pre-heat temperature:800-850℃

- Quenching temperature:1020-1050℃

- Quenching medium: air or oil

- Quenching hardness:55-58HRC

H13 Steel Tempering Details:

- Tempering temperature:560-580℃

- More than twice of tempering is necessary

- Hardness:47-49HRC

H13/DIN 1.2344 STEEL BUYING GUIDE

As the most representative steel grade in the field of hot work tool steels,H13 and DIN 1.2344 steel have an extremely wide range of industrial application requirements.As demanders, they often have no way to start with materials with different quality levels on the market.This is a challenging job that tests experience and ability.

As experienced people, here, we will help and guide those in need to complete this challenge. If you have this need, then start learning from here.

WHAT IS H13/DIN 1.2344 STEEL?

We often hear customers talking about the excellent performance of H13 steel, but do we really know what H13 steel represents?In fact, H13 belongs to the hot work tool steel in the three major tool steel classifications in the United States, and is classified as a medium carbon high chromium series hot work tool steel.

Comparison of medium carbon and high chromium series hot work tool steel

| Grade | C | Si | Mn | P | S | Cr | Mo | V | W | Co |

| H10 | 0.35-0.45 | 0.80-1.25 | 0.2-0.7 | ≤0.03 | ≤0.03 | 3.0-3.75 | 2.0-3.0 | 0.25-0.75 | - | - |

| H11 | 0.33-0.43 | 0.80-1.25 | 0.2-0.6 | ≤0.03 | ≤0.03 | 4.75-5.5 | 1.1-1.6 | 0.3-0.6 | - | - |

| H12 | 0.30-0.40 | 0.80-1.25 | 0.2-0.6 | ≤0.03 | ≤0.03 | 4.75-5.5 | 1.25-1.75 | 0.2-0.5 | 1.0-1.7 | - |

| H13 | 0.32-0.45 | 0.80-1.25 | 0.2-0.6 | ≤0.03 | ≤0.03 | 4.75-5.5 | 1.1-1.75 | 0.8-1.2 | - | - |

| H14 | 0.35-0.45 | 0.80-1.25 | 0.2-0.6 | ≤0.03 | ≤0.03 | 4.75-5.5 | - | - | 4.0-5.25 | - |

| H19 | 0.32-0.45 | 0.15-0.50 | 0.2-0.5 | ≤0.03 | ≤0.03 | 4.0-4.75 | 0.3-0.55 | 1.75-2.2 | 3.75-4.5 | 4.0-4.5 |

For DIN 1.2344 steel,it belongs to the German standard DIN 17350.As a steel grade against H13, it must belong to the hot work tool steel series. It is named 1.2344 according to the German DIN 17007 numerical steel number system,which is expressed as hot work tool steel. In addition, 1.2344 corresponds to X40CrMoV5-1 under the DIN 17006 naming system.

The Main Characteristics of H13 Steel

- High Hardenability & Toughness

- Excellent thermal cracking resistance, suitable for water-cooled workplaces

- Medium wear resistance, suitable for carburizing or nitriding process to increase its surface hardness, but slightly reduce thermal cracking resistance

- Good high temperature resistance to softening, but the hardness drops rapidly when the temperature is higher than 540°C (1000°F) (that is, the working temperature of the ability is 540°C)

- Small heat treatment deformation

- Moderate resistance to decarburization

- Good cutting performance and polishing performance

Classification of Hot Work Tool Steel

Common American hot work tool steel codes

| Steel Series | Hot Work Tool Steel Categories |

| H1X | Medium carbon high chromium Series |

| H2X | Tungsten Series |

| H4X | Molybdenum series |

Chromium Hot Work Tool Steels

This group of steel products H10 to H19 contains chromium, with tungsten, molybdenum, vanadium and cobalt additions in some cases.

The carbon of this group is considered to be rather low, about 0.35-0.40 percent, thus promoting toughness at a normal working strength between 400 and 600 HV, along with the relatively low total alloy content.

The large chromium in these units, combined with low carbon, guarantees a depth of hardening and therefore the air can be hardened in parts of up to 30 cm to fully work hard.

The higher tungsten and molybdenum levels of steels H10 and H14 increase the hardness of the red and heat, but reduce toughness possibly a bit.

Applications

The following are the application of the chromium hot-work steels:

- Forging dies, mandrels, hot shears, punching blades, and for extrusion of aluminum and magnesium

- Hot-work and structural applications

- Highly stressed structural parts used in aerospace technology

- Die casting, forging, piercing, heading, extrusion, trimming purposes.

Molybdenum Hot Work Tool Steels

Molybdenum, chromium and vanadium, along with tungsten and different percentages of Carbon are the main alloying elements in this group.

Like high-speed steels the grades of molybdenum in hot working steels have nearly the same characteristics and use as tungsten. Compared to the former group, the main benefit of these steels is excellent resistance to heat

More care is needed in thermal treatment in order to prevent decarburization along with all high molybdenum steels.

Applications

The following are the application of the hot molybdenum steels

- The purpose to cast, forge, pierce, heading, extrusion and trim.

- Hot-shear and punching blades.

Tungsten Hot Work Tool Steels

Carbon, tungsten, chromium and sometimes vanadium are the primary alloying elements of these steels.

Compared with straight chromium steels, the high alloy content increases resistance to high temperatures softening, but the steels in this category are volatile. The normal toughness of work is between 450 and 600HV.

The large content of tungsten makes the group in contrast to the steels in the hot work chromium unit unsuitable for water cooling.

If we look at this group of steels, the composition of the steels resembles high speed steels, and Type H26 is in fact a high speed steel low carbon version of T1.

Applications

The following are the application of the Tungsten hot work steels:

- Manufacturing mandrels and extrusion dies for high temperature applications, such as extrusion of brass, nickel alloys, and steel

- Hot-forging dies of rugged design

QUICK FAQS FOR H13/DIN 1.2344 STEEL

Is H13 an alloy steel?

First of all, H13 steel is definitely alloy steel, and the total alloy content is between 5% and 10%. Therefore, strictly speaking, we can define H13 steel as a medium alloy hot work tool steel.

How hard is H13 steel?

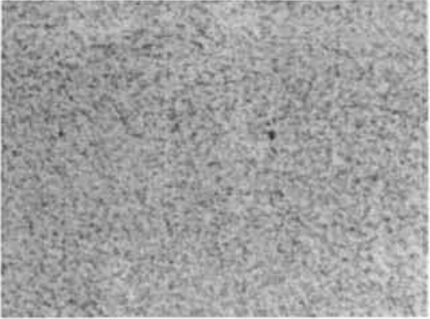

When H13 steel is delivered in annealed condition,the ideal structure is composed of spherical pearlite and a small amount of granular carbide,its hardness is usually less than 235HBW.

Metallographic structure of H13 annealed steel

After quenching and tempering, the performance of H13 steel will be greatly improved, and its hardness can usually be maintained above 52HRC.

What is the strength of H13 steel?

As a hot work tool steel, under the harsh working conditions of high temperature and high pressure for a long time, it is easy to cause material failure. Therefore, the performance of H13 steel is a very severe test.

In practical production, H13 steel must be able to serve safely for a long time under such working conditions, therefore, it must have extremely excellent strength.

According to experience, the tensile strength of H13 steel should be greater than 1500MPa at room temperature.

At the same time, at high temperature (below 600°C), H13 steel should have the ability to resist mechanical load, that is, the yield strength to maintain the shape and the strength and toughness to avoid breaking. Production experience shows that at working temperature, the yield strength of H13 steel should not be lower than 1000MPa.

Can H13 steel be nitrided?

In order to ensure the service life of the H13 steel mold, surface nitriding treatment is the most commonly used strengthening method.After two nitriding treatments, the thickness of the nitriding layer of H13 steel can reach more than 200um, and its surface hardness can reach 1100HV.

Why H13 steel usually needs to be tempered more than 2 times?

The H13 steel after quenching has high hardness (55-58HRC), but its toughness is not ideal.According to experience, H13 steel will form a lot of internal stress after quenching. If it is not eliminated in time, the stress will be released during use and the material will eventually crack.

Therefore, H13 steel must be tempered after quenching, and in order to achieve the best performance, the number of tempering should be 2-3 times.

It should be pointed out that secondary hardening will occur when H13 steel is tempered at 425°C~520°C, accompanied by the second type of temper brittleness, which will significantly reduce the impact toughness.

If the second tempering is adopted, the second tempering temperature should be about 10°C lower than the first tempering temperature, and the holding time should be shortened by 20%~25%, which can be used to reduce temper brittleness.

Why H13 steel can only be used at temperatures below 600°C?

The final heat treatment structure of H13 steel after tempering is tempered sorbite + a small amount of granular carbide.

When the tempering temperature is lower than 600℃, its structure still maintains martensitic lath. However, once the tempering temperature is higher than 650°C, the martensite form will gradually disappear and transform into tempered martensite, which will cause serious deterioration of the thermal strength of H13 steel.

Therefore, H13 steel is a medium temperature (<600°C) hot work tool steel with excellent performance.

H13 Steel VS H11 Steel

After the previous introduction, we clearly know that both H13 steel and H11 steel belong to medium carbon high chromium hot work tool steel.It can be clearly seen from the table below that the main difference in their chemical composition lies in the V element content, that is, the V in H11 steel is 0.5% lower than that in H13 steel.

| Grade | C | Si | Mn | P | S | Cr | Mo | V |

| H11 | 0.33-0.43 | 0.80-1.25 | 0.2-0.6 | ≤0.03 | ≤0.03 | 4.75-5.5 | 1.1-1.6 | 0.3-0.6 |

| H13 | 0.32-0.45 | 0.80-1.25 | 0.2-0.6 | ≤0.03 | ≤0.03 | 4.75-5.5 | 1.1-1.75 | 0.8-1.2 |

We can consider H13 steel as an improved version of H11 steel. The increase of V content in H13 steel can significantly improve the hardness, wear resistance and tempering stability.

In addition, from the analysis of the chemical composition and the use status of the mold factory, generally speaking, the service life of H13 steel is longer than that of H11 steel for the same product.

HOW TO MANUFACTURE HIGH QUALITY H13 STEEL?

H13 steel is the most widely used and most representative air-cooled hardening hot work die steel, which has both strong and tough mechanical properties and good cold and thermal fatigue properties.

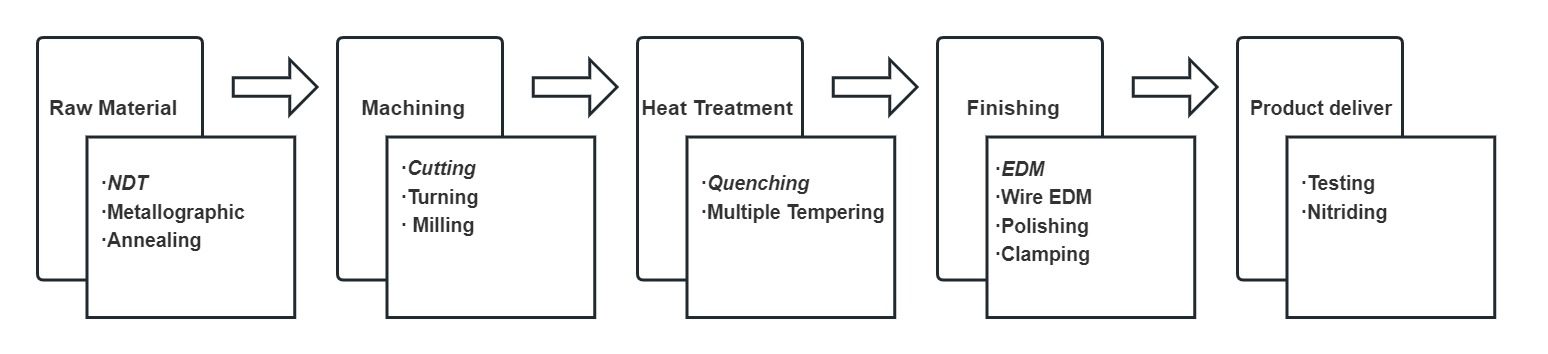

H13 steel is mainly used in hot extrusion dies with a working temperature below 600°C, and the material must go through a series of manufacturing processes to achieve its application purpose, so that it can work stably for a long time in the harsh environment of hot extrusion.The figure below shows the general production process of H13 tool steel.Next, we will briefly talk about the process points that we think need to be focused on.

Ingot Melting

At present, there are two commonly used smelting methods for H13 steel, namely electric furnace smelting + electroslag remelting (EF+ESR) and electric furnace smelting + vacuum refining outside the furnace (EF+LF+VD).

Due to different smelting methods, compared with electroslag steel, H13 electric furnace steel has poor compactness and low purity. Especially in the annealed condition, H13 electric furnace steel has serious band segregation and uneven structure.

Relatively speaking, the cost of H13 electric furnace smelting is low, but a large number of production practices have proved that the H13 steel produced by electric furnace smelting has low transverse toughness and cannot meet the application standards.

Based on the smelting of electric furnace steel, H13 electroslag steel is subjected to secondary smelting in vacuum, which further improves the purity of the steel, further reduces the gas content, and further improves the physical and chemical properties.Therefore, electroslag smelting plays an important role in controlling the cleanliness and uniformity of H13 steel, and it can be used as an important process link in the production of high-quality H13 steel.

Heat Treatment

H13 steel must undergo a heat treatment process to strengthen its performance, so that it can work stably for a long time in the harsh environment of high temperature and high pressure. Generally speaking, the heat treatment process of H13 tool steel includes: Annealing, Quenching, and Tempering.

- Annealing

H13 steel can be considered as hypereutectoid steel, and conventional annealing process can be used, that is, complete annealing or isothermal spheroidizing annealing.

1.H13 steel complete annealing process: 850°C ~900°C x3h~4h heat preservation, cooling to below 500°C with the furnace, and then finally air cooling after being out of the furnace.

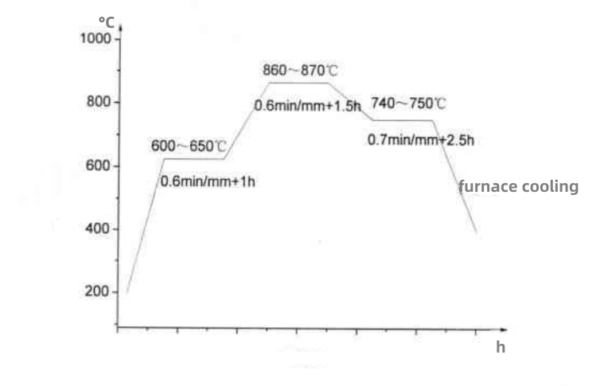

2.H13 steel isothermal spheroidizing annealing process: 845°C ~900°C x2h~4h/furnace cooling +700°C ~740°C x3h~4h/furnace cooling, <40°C /h cooling rate, ≤500°C out of the furnace and finally air cooling.

H13 steel Isothermal Spheroidizing Annealing Diagram

3.For H13 steel molds with high quality requirements, in order to prevent white spots, dehydrogenation annealing should be arranged

4.For H13 molds with complex shapes,stress relief annealing should be performed after rough machining: 600°C~650°Cx2h/furnace cooling.

5.After the heat treatment of the H13 steel mold, if the mold cavity is formed by grinding, EDM and wire cutting, a layer of quenched martensite white layer with a thickness of about 10m~30um will be formed on the surface of the mold.

Due to the large internal stress in the white layer and the brittleness of the quenched martensite itself, it is easy to produce microcracks and grinding cracks on the surface during grinding.Therefore, after grinding, it is best to perform stress relief annealing at a temperature lower than 50°C below the tempering temperature to eliminate grinding stress.

- Quenching

Quenching is the most important heat treatment process for H13 steel. During the quenching process, the austenite at high temperature is quenched into martensite, which greatly improves the hardness and strength of the mold and ensures the service life of the mold.

There are two main types of quenching equipment, vacuum heating and quenching, and atmosphere protection electric furnace heating and quenching. The commonly used media for quenching mainly include oil, water, salt bath furnace and vacuum air quenching.

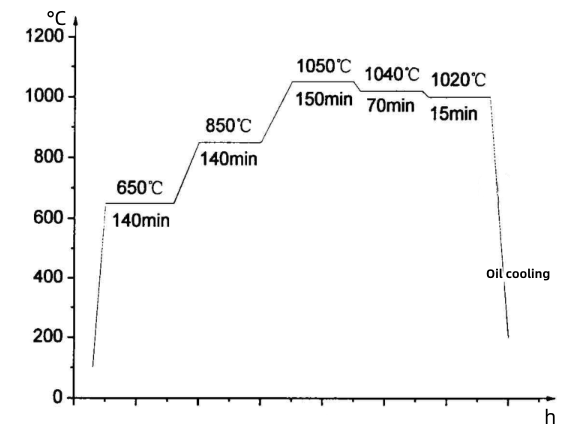

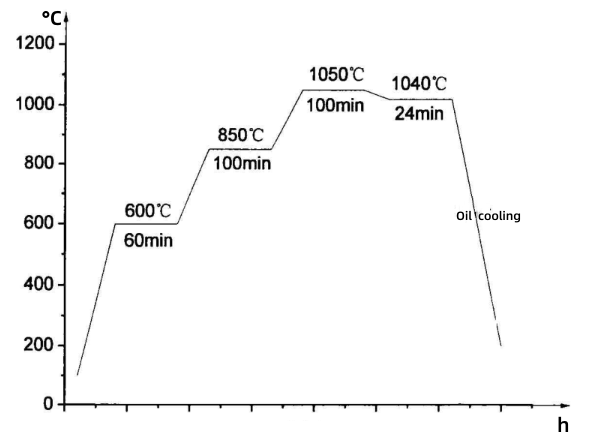

H13 steel is generally preheated in two stages when heating and austenitizing. Usually, the first stage preheating temperature is selected at about 650°C, and the second stage is selected at about 850°C. The purpose of segmental preheating of H13 steel is to make the internal and external temperature of the material fully uniform, to avoid the stress caused by the temperature gradient formed in the mold cavity by too fast heating, which will cause the distortion of the mold, and to effectively promote the homogenization of austenite.

The austenitization temperature of H13 steel is 1010°C to 1050°C. In this process, the core and surface of the mold should be kept as consistent as possible. The actual quenching temperature needs to be determined according to the working conditions and structural shape of the mold. , manufacturing process and performance requirements.

Therefore, in order to obtain the highest red hardness, the upper limit of austenitization temperature can be used for molds that have high requirements for fracture toughness, thermal fatigue resistance and thermal wear resistance, and that require electrical machining after quenching. For molds that require small distortion, fine grains, and high impact toughness, in order to obtain the best toughness and prevent cracking, the lower limit of austenitization temperature should be used.

The optimization of the holding time for quenching heating should ensure the completion of the transformation of the structure and obtain the required degree of solid solution of the alloying elements. If the holding time is too short, the red hardness and tempering resistance of H13 steel will be reduced.

H13 Steel Quenching Diagram in Atmosphere Protection Electric Furnace

H13 Steel Quenching Diagram in Vacuum Oil Quenching Furnace

H13 steel can be quenched by air quenching, gas quenching, oil quenching or stepwise quenching at 500C~540°C. For molds requiring high strength and toughness, a high quenching rate should be used to suppress the intergranular precipitation of carbides and the appearance of upper bainite, and improve its strength, toughness and tempering resistance. However, the cooling rate must be controlled within the allowable range without quenching cracking and distortion.

The structure of H13 steel after oil quenching is shown in the figure below as lath martensite + undissolved carbide + retained austenite.

- Tempering

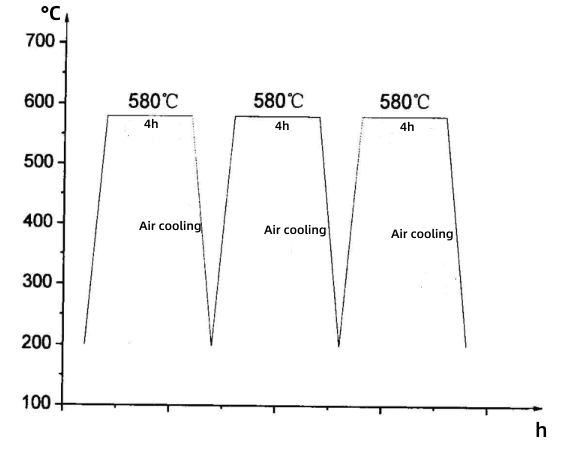

The H13 steel after quenching has high hardness, but its toughness is not ideal. Since quenching produces a lot of internal stress, if it is not eliminated in time, the stress will be released during use and cause mold cracking. Therefore, the H13 steel mold must be tempered after quenching, and in order to achieve the best performance, the number of tempering is 2-3 times.

The tempering process of H13 steel should determine its tempering temperature according to the working conditions and performance requirements of the mold.Generally, high-quality H13 steel is tempered at a high temperature of 540°C-650°Cx3h to improve the toughness of the mold and reduce the brittleness caused by the transformation of retained austenite in the mold.

Special attention should be paid to the fact that H13 steel has high temperature temper brittleness, that is, the second type of temper brittleness, which significantly reduces the impact toughness of H13 steel.This phenomenon is caused by the precipitation of large carbides between martensite laths during tempering of H13 steel, and the transformation of retained austenite into martensite during rapid cooling after tempering.

H13 Steel Tempering Diagram

Metallographic structure of H13 steel after quenching and tempering

WHERE CAN YOU BUY HIGH QUALITY H13/DIN1.2344 STEEL?

Whether you need round bar, flat bar or square bar of H13 steel, we can help you, we always supply high quality H13 steel.

Over the years, we have received the support and trust of countless customers all over the world!Like them, cooperate with us, I believe you can also get world-class quality H13 steel! Never settle for less! Work with us to get plentiful supply of H13 Steel at best and most competitive price.

What We Supply For H13/DIN 1.2344 Steel

- Rolled Round Bar:Φ8-Φ130mm

- Forged Round Bar:Φ80-Φ600mm

- Flat Bar:Thickness :16-500mm ,Width:200-800mm

- Customized service:Special Size & Length

- Delivery Condition: Annealed

- Free Sample of H13/DIN 1.2344 Steel