COMMON APPLICATIONS FOR 4140 STEEL

4140 steel is a high-quality alloy with molybdenum and chromium as alloying elements. It has very good mechanical properties, including high tensile strength over 43 ksi (310 MPa) and yield strength over 35 ksi (240 MPa). Furthermore, it can be quickly mach ined to close tolerances. This steel is often used in the manufacture of machinery parts, such as shafts, crankshafts, bolts, gears, milling spindles, and nuts.

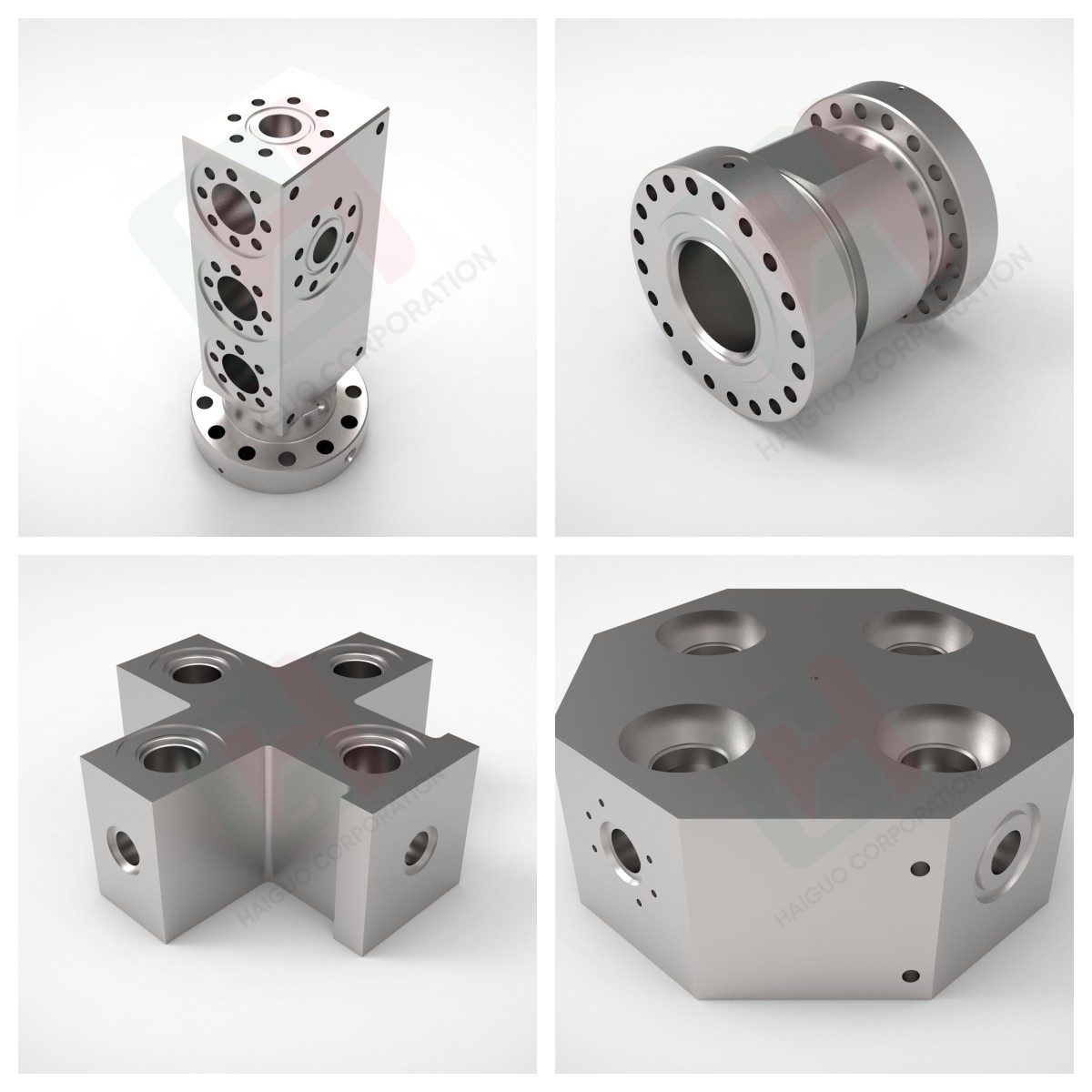

4140 STEEL APPLICATIONS IN OIL &GAS INDUSTRY

4140 steel forgings are mainly used in oil and gas equipment, which are divided into forgings for wellhead devices and Christmas tree equipment and forgings for deep sea oil and gas equipment.

Wellhead devices and Christmas tree equipment are important equipment for oil and gas production, consisting of three parts: casing head, tubing head, and oil (gas) tree. It can control the pressure of the production wellhead and adjust the flow rate of the oil (gas) wellhead, and can also be used for acidizing Special operations such as fracturing, water injection, and testing.

The structure of deep sea oil and gas equipment is similar to that of onshore and shallow sea oil and gas equipment, including Christmas trees, manifolds, valve bodies and other components, but deep sea oil and gas equipment has higher requirements on the performance indicators of forgings such as bearing pressure and corrosion resistance.4140 Steel can be applied to tubing heads, casing heads and various valve bodies for deep-sea oil and gas equipment of various pressure levels.

4140 STEEL FOR COLLETS

One common use for 4140 steel is in collets. Collets are used to secure workpieces in a lathe. A lathe is a machine that is used to create round products out of raw material, in this case steel. Since collets are exposed to high levels of pressure and force, they need to be constructed of durable materials. 4140 Steel is an ideal material because it can hold its form, even under extreme heat or pressure, which makes the product more efficient and consistent.

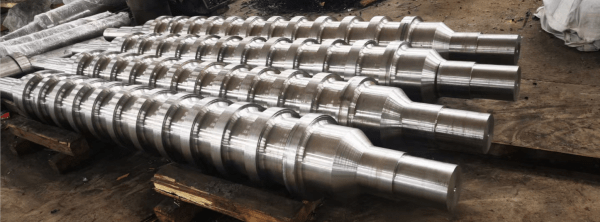

4140 STEEL FOR CONVEYORS

Another example of steel in action is on a conveyor and roll. Conveyors are very common pieces of material handling equipment. The conveyor transports materials as well as people from one place to another, such as on an assembly line or shipping dock. One part of the conveyor that is critical for proper use is the roll. The roll is a metal cylinder that the belt or chain travels around. It is important that the roll be made of a durable material, such as 4140 steel, so that it can withstand the constant wear and tear from the belt or chain.

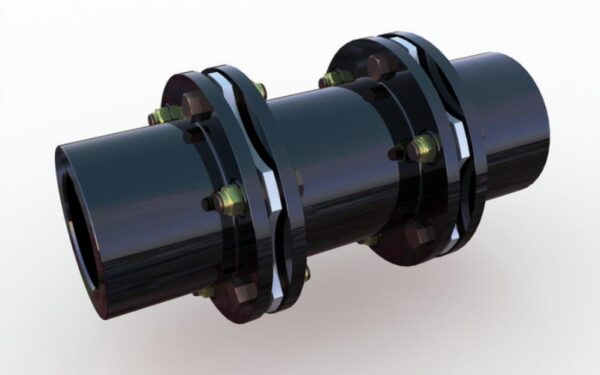

4140 STEEL FOR COUPLINGS

A third example of steel in use is in a coupling. Couplings are devices that are used to connect two shafts together. This is often done in order to transfer power or motion between the two shafts. There are many different types of couplings, but all of them need to be made from a strong material so that they can withstand the forces that are applied to them. 4140 Steel is an ideal choice for this purpose because it is durable and reliable in most situations.

4140 STEEL FOR DRILL COLLARS

Another component that is commonly fabricated from steel is a drill collar. Drill collars are used in many different drilling operations, such as the oil and gas industry or in water wells. Often times, drill collars can be up to 20 feet long and weight several tons due to the extreme pressure that is applied to them. A drill collar needs to be made from a strong material, such as 4140 steel, because it experiences extreme heat and pressure that can cause many different materials to warp or break.

4140 STEEL FOR EJECTORS

Another common use for steel is in an ejector. Ejectors are used in many different applications where fluids need to be forced out of a product. For example, ejectors are used in engines and pumps. Since they experience high heat and pressure, it is important that an ejector is made from a strong material like steel. Not only will the ejector be stronger and more reliable if it is made from steel, but it will also last longer than other materials due to its durability.

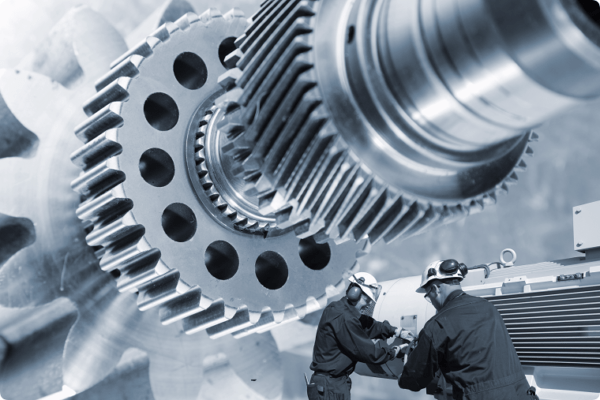

4140 STEEL FOR GEARS

Gears are used in many different applications, whether it be to transfer power or motion from one shaft to another. Large gears are often made from steel because it can withstand the high levels of friction and heat that is produced by an application such as this. Not only will steel stand up to the heat and friction, but it will also last much longer than other materials, making it a more cost-effective option in the long run.

4140 STEEL FOR SHAFT

The shaft is a rotating element that transmits power from one component to another. It may be made from a variety of materials, including steel, aluminum, and titanium. Steel shafts are often used in heavy machinery because they have high tensile strength and can withstand high levels of stress. Additionally, they can be machined to close tolerances for a precise fit.

4140 STEEL FOR CRANKSHAFT

The crankshaft is an important component of the internal combustion engine. It converts the linear motion of the pistons into rotational motion, which then powers the vehicle. The crankshaft is made from a strong material like steel so that it can withstand the high levels of stress it experiences. Additionally, it is machined to close tolerances for a precise fit.

4140 STEEL FOR BOLT

A bolt is a type of fastener, often made from steel, that secures one object to another. The bolt has a threaded stud at one end so that it can be screwed into the receiving component. Though bolts are simple in concept, they have several important features. For instance, they must withstand high forces while being inserted or removed during assembly/disassembly. Additionally, they must be tightened to a precise specification to ensure a secure fit.

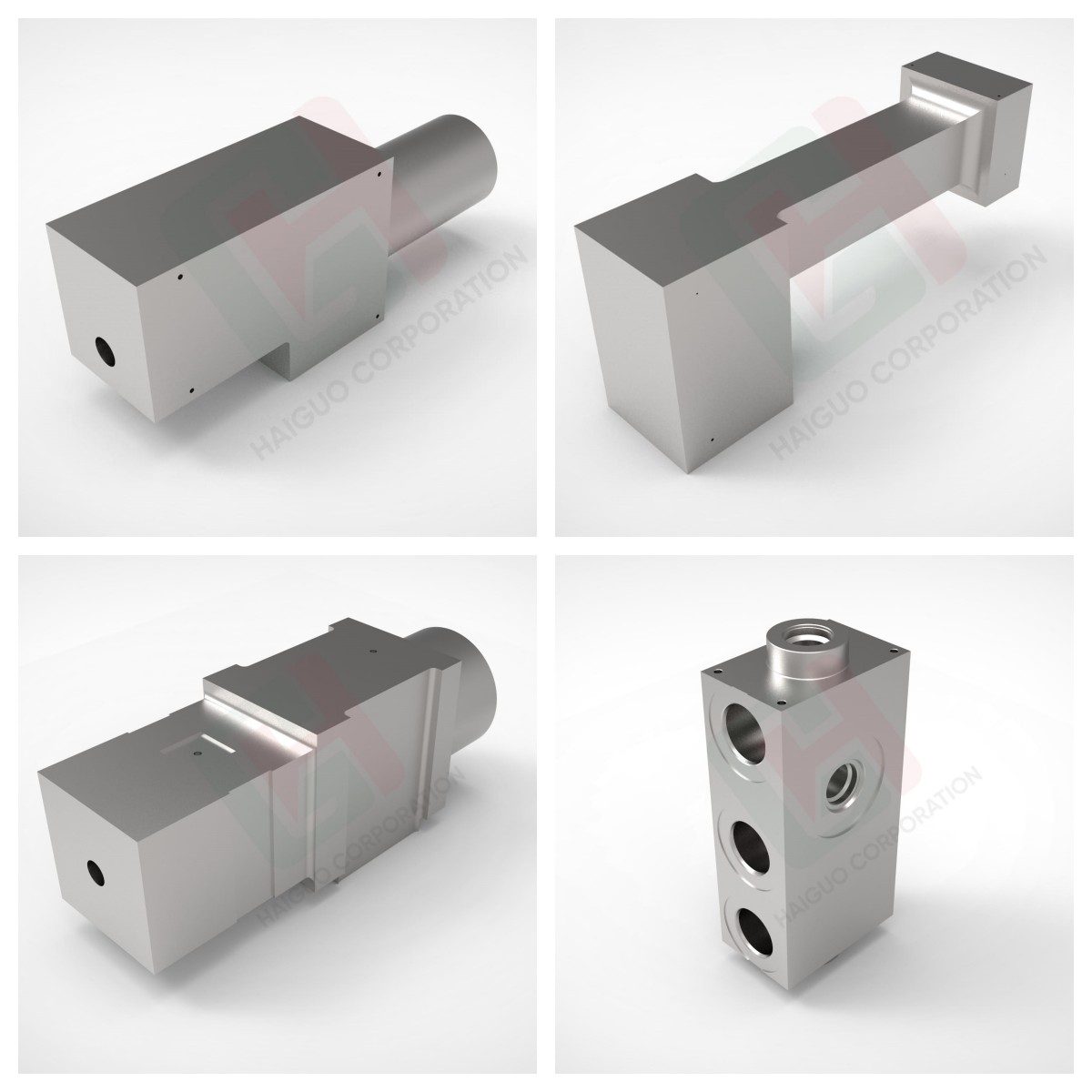

4140 STEEL FOR MACHINERY PARTS

Machine parts are components that make up the machinery used in factories and other industrial settings. They can be made from a variety of materials, including steel, aluminum, and titanium. Steel parts are often chosen because they have high tensile strength and can withstand high levels of stress. Additionally, they can be machined to close tolerances for a precise fit.

4140 STEEL FOR MILLING SPINDLE

A milling spindle is a rotating cutting tool used in machine tools. One of its main features is the fact that it can be mounted onto the machine’s table and shafted so that it rotates as various other components move along the X, Y, and Z axes. The milling spindle is made from strong steel so that it can withstand the high levels of stress it is subjected to.

4140 STEEL FOR NUT

The nut is a threaded fastener with one or more threads on its outer surface that allow it to be tightened in place once inserted into another component. For instance, when tightening an external fastener, the nut is threaded onto the external stud before it is tightened in place with a wrench. Nuts are often made from steel because it has high tensile strength and can withstand high levels of stress. Furthermore, it can be machined to close tolerances for a precise fit.

4140 STEEL FOR SLIDE

A slide is an assembly that allows two components to move parallel to one another. It is often made from steel because it has high tensile strength and can withstand high levels of stress. Additionally, slides can be machined to close tolerances for a precise fit.

In conclusion, 4140 steel is a high-quality alloy that has many desirable properties, including high tensile strength and resistance to wear and tear. It is commonly used in the manufacture of machinery parts, such as shafts, crankshafts, bolts, gears, milling spindles, and nuts. These parts are essential for transmitting power and ensuring the smooth operation of industrial machinery. Thanks for reading!