DIN 1.2316/X36CrMo17 steel is defined as plastic mould tool steel as per DIN 17350 standard,and it can also be considered a martensitic stainless steel due to its high chromium content of 15-17%.DIN 1.2316 steel is usually supplied in the pre hardened(33-38HRC) condition.

The Main Characteristics of DIN 1.2316/X36CrMo17 steel

- Excellent corrosion resistance

- Excellent wear resistance & toughness

- Uniform hardness

- Good thermal fatigue resistance

- Superior polishing performance

- High surface precision

- Low impurity content with high purity

DIN 1.2316/X36CrMo17 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 1.2316 | 0.33-0.43 | ≤1.0 | ≤1.0 | ≤0.03 | ≤0.03 | 15.0-17.0 | ≤1.0 | 1.0-1.3 |

DIN 1.2316/X36CrMo17 RELATED STANDARD & EQUIVALENT GRADE

Europe/EN/ISO4957:X38CrMo16

GB:3Cr17NiMo

DIN 1.2316/X36CrMo17 STEEL FORGING

- Initial Forging Temperature:1100-1150℃

- Final Forging Temperature: >850℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high alloy tool steel,DIN 1.2316 steel should be annealed after forging.

DIN 1.2316/X36CrMo17 STEEL HEAT TREATMENT

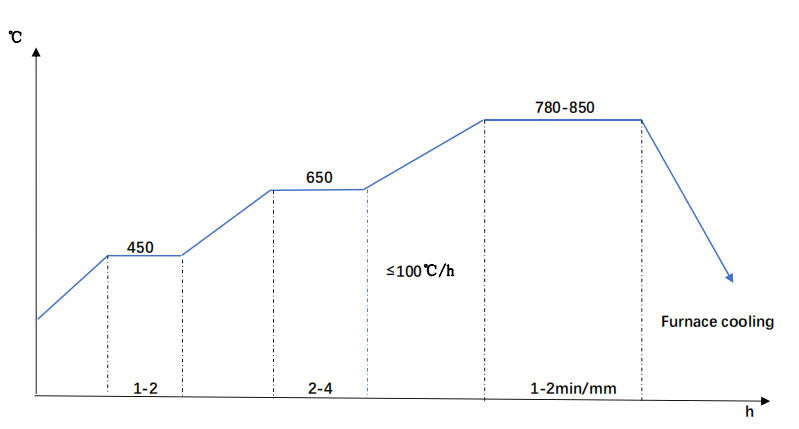

- DIN 1.2316 Steel Soft Annealing

The soft annealing temperature for DIN 1.2316steel is 780-850℃ with holding time 3-6h.With cooling ratw below 30℃/h, cooled to 550-600℃,then air-cooling.The hardness will be below 285HBW.

DIN 1.2316 Steel Soft Annealing Diagram

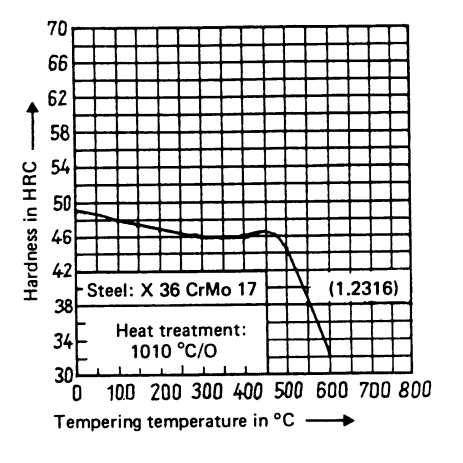

- DIN 1.2316 Steel Quenching & Tempering

Quenching Temperature:1000-1040℃

Quenching Medium:oil

Tempering Temperature:160-180℃ Followed by Quenching

Hardness:46-48HRC

Structure:tempered martensite

DIN 1.2316 Steel Tempering vs Hardness Diagram

DIN 1.2316/X36CrMo17 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |