INTRODUCTION

As the global demand for renewable energy continues to grow,wind power,as a clean and efficient form of energy, has been widely used. In the field of wind power generation, the selection and use of materials are of great significance to improving the efficiency of wind turbines and reducing costs.Therefore, this article will briefly introduce the application of several special steel forging materials in the transmission system of wind turbines.

Wind Power Spindle-Main Shaft

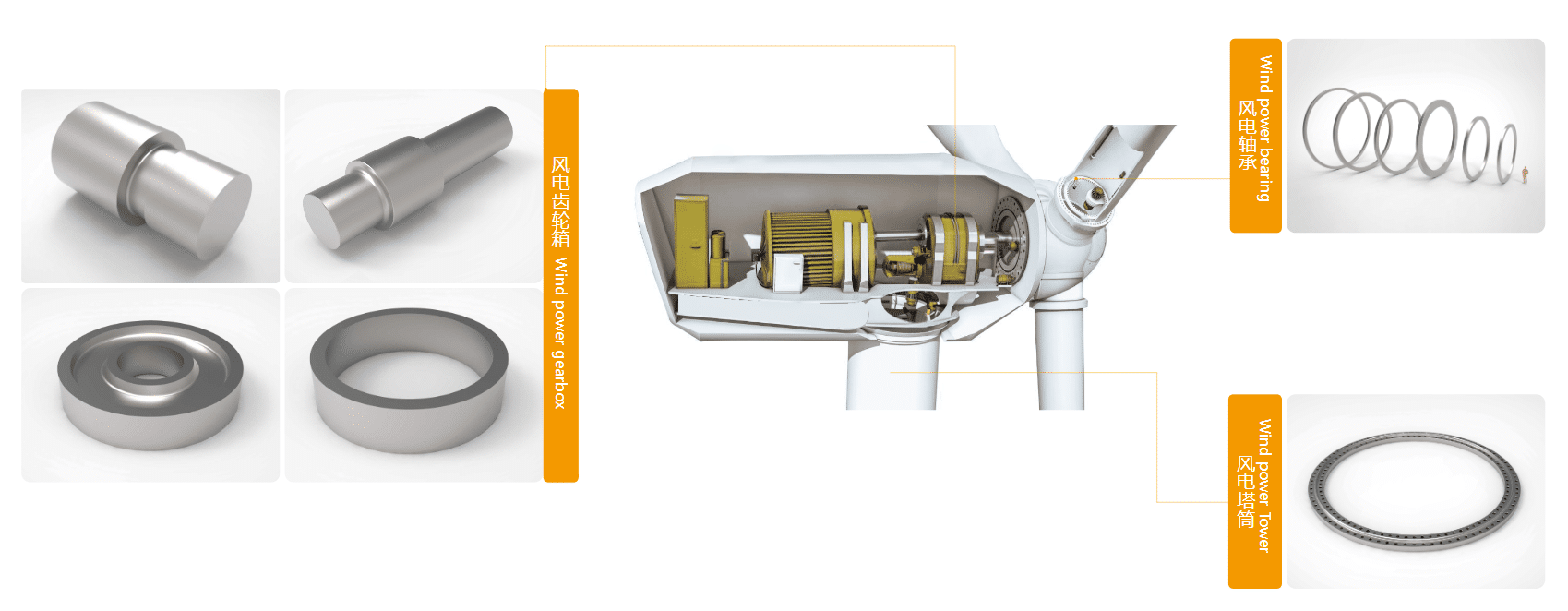

The wind power spindle is the core component of the wind turbine transmission system. The structure of the wind turbine is relatively complex, consisting of the wind wheel (blade, hub), main bearing, wind power main shaft, gearbox, generator and other parts. The hub, main shaft, gearbox, generator, etc. constitute the wind turbine generator transmission system. The wind power main shaft serves to connect the blade hub and gear box in the wind turbine, and undertakes the transmission and force-bearing functions.

As the main force-bearing component of wind turbines, wind power spindles are prone to breakage in harsh environments after long-term service.Since the wind turbines has a long service life of up to 20 years, it is difficult and costly to replace the main shaft.Therefore, customers have very strict requirements on spindle quality and performance, and need to choose special steel grades with better fatigue resistance.

Wind power spindles generally use steel 34CrNiMo6 or 42CrMo4 as the main material. Since the spindle has been used in a low-temperature environment for a long time, it often needs to go through several major processes such as forging, rough machining, inspection, heat treatment, finishing and painting to obtain the best comprehensive performance of the wind power spindle.

In wind power spindle manufacturing, 34CrNiMo6 steel has the following advantages:

- High strength

Through appropriate heat treatment process, 34CrNiMo6 steel can obtain high strength and hardness, which can meet the requirements of high load, high speed and high fatigue life of wind power spindle.

- High toughness

Compared with other alloy steels, 34CrNiMo6 steel has better low-temperature toughness and fracture toughness, and can maintain stable performance under harsh environmental conditions.

- Corrosion resistance

34CrNiMo6 steel contains 1.5% chromium, 1.5% nickel and a certain amount of molybdenum,so it has strong resistance to a variety of corrosive media,which can extend the service life of wind power spindles.

- Fatigue resistance

Through reasonable manufacturing technology and heat treatment technology, 34CrNiMo6 steel has good fatigue resistance under repeated loads, which can significantly improve the fatigue life of wind power spindles.

As an economical steel, 42CrMo4 steel is more reasonably priced than 34CrNiMo6 steel. Its good processing performance makes it easy to perform turning, milling, drilling and other processing, which reduces production costs.In short, 42CrMo4 steel has the advantages of high strength, hardness, corrosion resistance, good processing performance, heat treatment performance and economy, making it an excellent wind turbine spindle manufacturing material.

Recommended Related Articles

1.Steel Comparison:34CrNiMo6 Steel VS 42CrMo4 Steel

2.Steel Buying guide: How to Buy 34CrNiMo6 Steel?

3.Steel Buying guide: How to Buy 42CrMo4 Steel?

Wind Power Gearbox

The wind power gearbox is the core component of the wind turbine. Its main function is to convert the kinetic energy generated by the wind wheel under the action of wind into mechanical energy, and finally transfer it to the generator.

As a key component for converting large torque and low speed to small torque and high speed, wind power gearboxes are subjected to great impact when operating in various harsh environments such as low temperature and high altitude, resulting in frequent failures and inconvenient installation and maintenance.Therefore, the design life of wind power gearboxes must be more than 20 years, and the requirements for the fatigue resistance of materials are extremely strict.

There are many grades of materials for wind power gearboxes at home and abroad, such as 18CrNiMo7-6 and 8620, which are the steel types mainly used by European and American customers. In China, 20CrMnTi, 20CrNiMo, 20Cr2Ni4, etc. are often used as gear materials.

In wind power gearbox manufacturing, 18CrNiMo7-6 steel has the following advantages:

- High strength and hardness

- High core hardness and good toughness

- Good wear resistance

- Good fatigue resistance

- Good high temperature stability

- High cost performance

As a high-strength alloy steel, 18CrNiMo7-6 steel has broad application prospects in the wind power field. Its excellent comprehensive properties make it one of the ideal material choices in the wind power field. In the future, with the continuous growth of technological innovation and market demand, the application and development of 18CrNiMo7-6 steel in the wind power field will be broader.

Wind Power Bearing

Known as the “joint” of mechanical equipment, as a basic component of modern industry, the main function of bearings is to support rotating shafts or other moving bodies, guide rotation or movement, and bear the load transmitted by the shaft or parts on the shaft. Therefore, its accuracy, performance, life and reliability play a decisive role in the performance and reliability of the main equipment.

Wind power bearings are the core rotating components in wind turbines and are mainly divided into yaw bearings, main shaft bearings, transmission bearings, generator bearings, etc.

Due to the special service conditions of wind power bearings, which are usually harsh, they need to face a wide range of temperature and humidity changes, bearing load changes and impact loads.Therefore, in order to ensure the service life and reliability of bearings,the materials of wind power bearings need to have high strength, wear resistance, corrosion resistance, impact resistance and other properties.Commonly used materials include high carbon chromium bearing steel(100Cr6,GCr15,52100) carburized steel(8620,4118), stainless steel(440C), etc.

In wind power bearing manufacturing, 100Cr6 steel has the following advantages:

- High contact fatigue strength

- High hardness

- High wear resistance & Low friction coefficient

- High elastic limit

- Good impact toughness & Fracture toughness

- Good dimensional stability

- Good rust resistance

- Good cold and hot processing properties

As a key component in wind turbines, the performance and quality of wind turbine bearings directly affect the stability and efficiency of the entire system. Through continuous research and innovation, wind power bearings will be more efficient, reliable, intelligent and environmentally friendly in future development.