COLD DRAWING PRINCIPLE

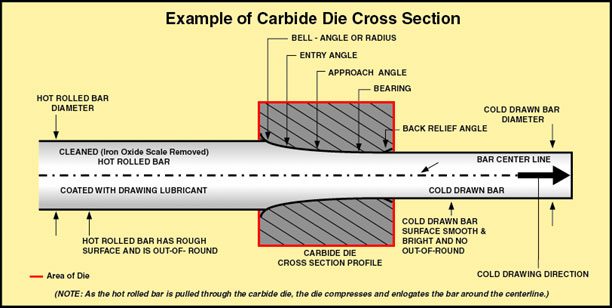

Cold drawing is a processing technology of materials. For metal materials, cold drawing refers to drawing at room temperature in order to achieve a certain shape and certain mechanical properties.

Cold drawing is usually a process of forcibly drawing the material through the hard alloy wire drawing die hole, which is stronger than pure drawing.The cold drawn material is not only stretched longitudinally, but also subjected to lateral extrusion at the same time. After one or more times of cold drawing, the internal lattice slips, the tensile strength can be increased by 50% to 90%, and the hardness is increased, but the plasticity is significantly reduced.

WHAT IS THE DIMENSIONAL ACCURACY OF COLD DRAWN ROUND STEEL?

- Diameter tolerance

Diameter,mm | h8 | h9 | h10 | h11 |

| Tolerance deviation,mm | ||||

| >3-6 | 0,-0.018 | 0,-0.030 | 0,-0.048 | 0,-0.075 |

| >6-10 | 0,-0.022 | 0,-0.036 | 0,-0.058 | 0,-0.090 |

| >10-18 | 0,-0.027 | 0,-0.043 | 0,-0.070 | 0,-0.110 |

| >18-30 | 0,-0.033 | 0,-0.052 | 0,-0.084 | 0,-0.130 |

| >30-50 | 0,-0.039 | 0,-0.062 | 0,-0.10 | 0,-0.160 |

| >50-80 | 0,-0.046 | 0,-0.074 | 0,-0.120 | 0,-0.190 |

- Product length & Tolerance

| Product Variety | Length of Finished Product | Length Tolerance |

| Cold Drawing Product | 1000-6000mm | 0/+20mm |

| Grinding Prodcut | 1000-4000mm | 0/+20mm |

- Straightness Tolerance

| Product Mode | Straightness Tolerance,mm |

| Standard Cold Drawing | 0.7/1000-0.5/1000 |

| Precision & High Precision | 0.4/1000 |

- Surface Roughness

| Product Mode | ||||

Surface Roughness,Ra(μm) | Grinding | High Precision Cold Drawing | Precision Cold Drawing | Standard Cold Drawing |

| 0.4 | 0.8 | 1.6 | 3.2 | |

WHAT SHAPES AND SIZE OF COLD DRAWN STEEL CAN BE MADE?

| Shapes | Size | Length |

| Round | Ф4-Ф100mm | 5-8m,Can be fixed to length |

| Hexagon | S6-S75 | 5-8m,Can be fixed to length |

| Square | 5x5-70x70 | 5-8m,Can be fixed to length |

| Flat | 2x10-20x140 | 5-8m,Can be fixed to length |

| Irregular | Accumulated more than 800 types,discuss separately | 5-8m,Can be fixed to length |

| Special Requirements | Processing according to customer's design | |

WHICH STEEL GRADES ARE SUITABLE FOR COLD DRAWN STEEL?

| Steel Type | ASTM/SAE | JIS | EN/DIN |

| Quality Carbon Steel | 1010,1018,1020, 1035,1045,1055,1060 | S10C,S20C,S35C, S45C,S55C | C15,C22,C35, C45,C55,C60 |

| Alloy Structure Steel | 5120,5140,4135, 4140,4340 | SMn420,SCr440, SCM430,SCM440,SNCM439 | 41Cr4,34CrMo4, 25CrMo4,42CrMo4,34CrNiMo6 |

| Spring Steel | 1066,6150 | SUP6,SUP10 | 51CrV4 |

| Bearing Steel | 52100 | SUJ2 | 100Cr6 |

| Stainless Steel | 410,420 | SUS410,SUS420 | X20Cr13,X30Cr13 |

| Tool Steel | M2 | SKH9 | 1.3343 |

| Free Cutting Steel | 1212,11L08,1215, 12L13 | SUM21,SUM32, SUM22L,SUM42 | 10S20,10SPb20, 9SMnPb28 |

WHAT ARE ADVANTAGES FOR COLD DRAWN STEEL?

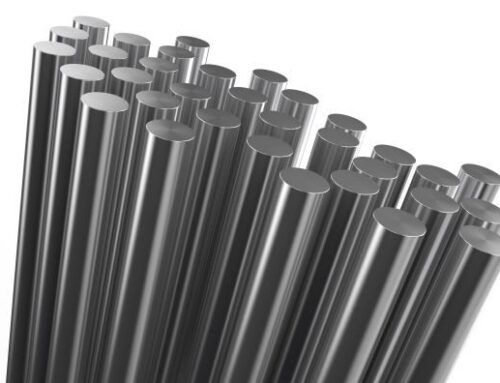

- Good Surface Quality

Before cold drawing, the material needs to be pickled to remove rust, and through phosphating and saponification treatment to form a dense metal soap film on the outer surfaces to reduce the friction between the material and the mold, and finally through the cold extrusion technology to make the surface of cold drawn steel becomes bright and smooth.

- High Accuracy

According to the design plan, cold-drawn steel has different shapes of abrasive tools, and cold-drawn different cross-sectional shapes, different specifications, and size tolerances. The angle of view can be designed as an oblique angle or arc.Cold-drawn steel uses high-quality cemented carbide molds to to ensure precise and uniform dimensional tolerances.

- Save Production Time

Due to its good surface quality and high dimensional accuracy, the surface layer grows steadily, and cold drawn products can be applied immediately, such as painting, sanding, bending, punching, or electroplating process immediately after fine drawing according to specific regulations,eliminating a lot of mechanical processing time and save the cost of equipping processing equipment.

- Save Raw Material

The cold drawing process is to transform the raw materials to the required shape, specifications and dimensional tolerances by hot forging. The loss of raw materials is very small.Relatively, using traditional CNC lathes to process the raw materials lost in drilling,and cutting materials, the saving of raw materials is obvious,especially when the amount of raw materials used is large, more raw materials will be saved considerably.

COLD DRAWN STEEL APPLICATIONS

- Automobile Industry

In automobile manufacturing, the largest number of cold-drawn steels are used in trucks and large passenger cars, which are mainly used to make carriage frames, wall panels, bottom plates, body frames, bottom beams, and door and window frames. The situation for medium-sized passenger cars is similar to that of large passenger cars. There are many varieties and specifications used in small cars, and most of the cross-sections are more complex, and the dimensional accuracy requirements are strict.

Trucks (including light trucks) use the largest number of cold-drawn sections in the compartment. According to different car models, the structure of the car model is also different. For example, the wall panel of the car compartment and the frame of the car compartment are integrated as a whole, and the components are of the same thickness; while the wall panel of the car compartment and the frame of the car compartment of some models are a separate component,and the thicknesses of the two components are different.

- Shipbuilding Industry

Due to the harsh working environment of the ship, the hull shell is subject to chemical corrosion, electrochemical corrosion of seawater and corrosion of marine organisms and microorganisms; the hull is subjected to large wind and wave shocks and alternating loads; The steel requirements for hull structure are strict.

First of all, good toughness is the most critical requirement. In addition, high strength, good corrosion resistance, welding performance, processability and surface quality are required. Cold drawn products can well meet the above requirements.

- Hardware Industry

Cold drawn products used in the hardware industry mainly include:

①Locks: exterior door locks, handle locks, drawer locks, ball door locks, glass window locks, electronic locks, chain locks, anti-theft locks, bathroom locks, padlocks, etc

② Doors and windows: rails, latches (light and dark), door suction, floor suction, floor spring, door clip, door closer, plate pin, etc

③Architectural hardware: stainless steel pipes, rivets, cement nails, advertising nails, mirror nails, expansion bolts, self-tapping screws, goods support tools, hacksaws, hand saw blades, pliers, screwdrivers (slotted, cross), tape measure,etc

④Kitchen and home appliance hardware: kitchen cabinet pendants, sinks, sink faucets, scrubbers, range hoods, gas stoves, ovens, water heaters, pipes, natural gas, liquefaction tanks, gas heating stoves, dishwashers, disinfection cabinets, etc.

- Machinery Industry

Cold drawn products used in the machinery industry mainly include:

①Basic machinery: bearings, hydraulic parts, seals, powder metallurgy products, standard fasteners, industrial chains, gears, molds, etc.

②Construction machinery: forklifts, shovel transport machinery, compaction machinery, concrete machinery, etc.

③ Machine tools: metal cutting machine tools, forging machines, casting machines, woodworking machines, etc.

④Environmental protection machinery: water pollution prevention and control equipment, air pollution prevention and control equipment, solid waste treatment equipment, etc.

⑤Packaging machinery: packaging machines, case packing machines, conveyors, etc.

THE FUTURE DEVELOPMENT AND TREND OF COLD DRAWN STEEL

At present, due to its own advantages, cold drawn materials have been widely used in various industries, such as various building structures and engineering structures, machinery, ships, automobiles and hardware parts.

The development of cold drawing technology has achieved good economic benefits. From the perspective of industry development trends, cold drawing should focus more on the following points.

- Cold drawing of special materials

- Development and design of cold drawing dies

- High precision control of surface and size

- Fully automatic integrated operation