C60 steel is an unalloyed medium carbon engineering steel which has 0.57%-0.65% Carbon as per EN10083 standard.It has characteristics similar to that of C55 carbon steel which has high hardness and high strength after hardening.C60 is difficult to weld,and machinability is poor due to high carbon content.This steel is generally supplied in an untreated or normalised condition.

1.Supply Form & Size & Tolerance

Hot Forged round bar:Φ130-Φ1000mm,Length:3000-10000mm

Flat bar/Blcoks:Thickness :120-800mm xWidth:120-1500mm,Length:2000-6000mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cr+Mo+Ni |

| C60/1.0601 | 0.57-0.65 | 0.60-0.90 | ≤ 0.045 | ≤ 0.045 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C60E/1.1221 | 0.57-0.65 | 0.60-0.90 | ≤ 0.03 | ≤ 0.035 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C60R/1.1223 | 0.57-0.65 | 0.60-0.90 | ≤ 0.03 | 0.02-0.04 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

3.Relevant Standards

| USA | UK | China | Japan | Australia |

| 1060 | 070M60 | 60# | S60C | 1060 |

4. Mechanical Property

| Mechanical properties a at room temperature in the quenched and tempered condition (+QT) | |||

| Diameter d mm | ≤ 16 | 16-40 | 40-100 |

| Thickness t mm | < 8 | 8-20 | 20-60 |

| Yield Strength Mpa | ≥580 | ≥520 | ≥450 |

| Tensile Strength Mpa | 850-1000 | 800-950 | 750-900 |

| Elongation, % | ≥11 | ≥13 | ≥14 |

| Reduction of area ,% | ≥25 | ≥30 | ≥35 |

| Mechanical properties a at room temperature in the normalized condition (+N) | |||

| Diameter d mm | ≤ 16 | 16-100 | 100-250 |

| Thickness t mm | ≤ 16 | 16-100 | 100-160 |

| Yield Strength Mpa | ≥380 | ≥340 | ≥310 |

| Tensile Strength Mpa | ≥710 | ≥670 | ≥650 |

| Elongation, % | ≥10 | ≥11 | ≥11 |

5.Forging

C60 steel forging temperature:900 – 1100°C ,cooling as slowly as possible in sand after forged.

6.Heat Treatment

- Normalizing: 820 – 880°C,Cooling in air

- Soft Annealing:680 – 710°C,Cooling in furnace

- Hardening:810 – 850°C,water or oil quench

- Tempering:550 – 660°C,Cooling in air

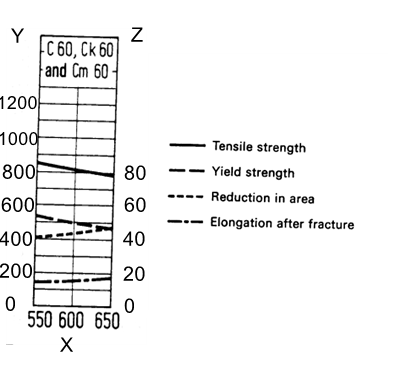

Guideline value Curve for C60 Steel Mechanical Property

X:Tempering temperature,oC

Y:Tensile and Yield Strength,Mpa

Z:Elongation and Reduction in area,%

7.Surface Hardness

- Treated to improve shearability (+S):Max 255HB

- Soft annealed (+A):Max 241HB

| NORMAL HARDENABILITY +H (Hardness HRC – distance mm) | ||||||||||||||||

| HRC - mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 15 | 20 | 25 | 30 |

| MAX | 67 | 66 | 65 | 63 | 62 | 59 | 54 | 47 | 39 | 37 | 36 | 35 | 34 | 33 | 31 | 30 |

| MIN | 60 | 57 | 50 | 39 | 35 | 33 | 32 | 31 | 30 | 29 | 28 | 27 | 26 | 25 | 23 | 21 |

8.Application

C60 is an unalloyed heat treatable steel. It is mainly used forparts of mechanical and vehicle engineering.Typical application such as: wheels, rims, toothed shafts, cylinders, shafts, axles, pins, screwdrivers, pliers and similar items.