C55 steel is an unalloyed medium carbon engineering steel which has 0.52%-0.6% Carbon as per EN10083 standard.It will obtain high hardness and high strength after hardening due to the relatively high carbon content,and also can be flame or induction hardened to surface hardness Min 58HRC.C55 steel is generally supplied in an untreated or normalised condition.

1.Supply Form & Size & Tolerance

Hot Forged round bar:Φ130-Φ1000mm,Length:3000-10000mm

Flat bar/Blcoks:Thickness :120-800mm xWidth:120-1500mm,Length:2000-6000mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cr+Mo+Ni |

| C55/1.0535 | 0.52-0.6 | 0.60-0.90 | ≤ 0.045 | ≤ 0.045 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C55E/1.1203 | 0.52-0.6 | 0.60-0.90 | ≤ 0.03 | ≤ 0.035 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C55R/1.1209 | 0.52-0.6 | 0.60-0.90 | ≤ 0.03 | 0.02-0.04 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

3.Relevant Standards

| USA | UK | China | Japan | Australia |

| 1055 | 070M55 / EN9 | 55# | S55C | 1055 |

4. Mechanical Property

| Mechanical properties a at room temperature in the quenched and tempered condition (+QT) | |||

| Diameter d mm | ≤ 16 | 16-40 | 40-100 |

| Thickness t mm | < 8 | 8-20 | 20-60 |

| Yield Strength Mpa | ≥550 | ≥490 | ≥420 |

| Tensile Strength Mpa | 800-950 | 750-900 | 700-850 |

| Elongation, % | ≥12 | ≥14 | ≥15 |

| Reduction of area ,% | ≥30 | ≥45 | ≥40 |

| Mechanical properties a at room temperature in the normalized condition (+N) | |||

| Diameter d mm | ≤ 16 | 16-100 | 100-250 |

| Thickness t mm | ≤ 16 | 16-100 | 100-160 |

| Yield Strength Mpa | ≥370 | ≥330 | ≥300 |

| Tensile Strength Mpa | ≥680 | ≥640 | ≥620 |

| Elongation, % | ≥11 | ≥12 | ≥12 |

5.Forging

C55 steel forging temperature:900 – 1050°C ,cooling as slowly as possible in still air or in sand after forged.

6.Heat Treatment

- Normalizing: 825 – 885°C,Cooling in air

- Soft Annealing:650 – 700°C,Cooling in furnace

- Hardening:810 – 850°C,water or oil quench

- Tempering:550 – 660°C,Cooling in air

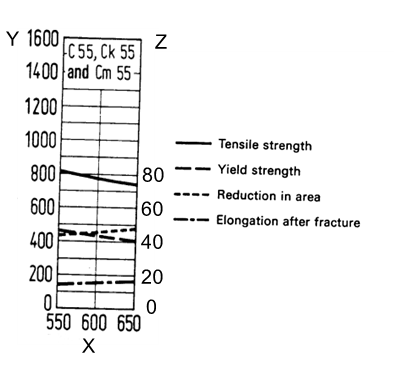

Guideline value Curve for C55 Steel Mechanical Property

X:Tempering temperature,oC

Y:Tensile and Yield Strength,Mpa

Z:Elongation and Reduction in area,%

7.Surface Hardness

- Treated to improve shearability (+S):Max 255HB

- Soft annealed (+A):Max 229HB

- Flame or induction hardening:Min 58HRC

| NORMAL HARDENABILITY +H (Hardness HRC – distance mm) | ||||||||||||||||

| HRC - mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 15 | 20 | 25 | 30 |

| MAX | 65 | 64 | 63 | 62 | 60 | 57 | 52 | 45 | 37 | 36 | 35 | 34 | 33 | 32 | 30 | 29 |

| MIN | 58 | 55 | 47 | 37 | 33 | 32 | 31 | 30 | 29 | 28 | 27 | 26 | 25 | 24 | 22 | 20 |

8.Application

C55 is a medium carbon steel suitable for various type of applications where high strength is needed.It is used for components of small cross section requiring low tensile strength, and heavy forgings in the normalized condition for automotive and general engineering such as axles, clutch members, shafts, pressed and punched parts, piston rods and gear racks.