AISI 4330V is a nickel-chromium-molybdenum-vanadium alloy steel that belongs to low-alloy high-strength structural steel.

As an improved version of 4330 alloy steel grade, 4330V improves hardenability by adding vanadium, and can obtain higher strength and low temperature impact resistance after quenching and tempering heat treatment.

4340V steel is suitable for parts subject to impact load or stress concentration. It is widely used in the oil and gas industry for applications such as oil tools, drill bits, tool holders and reamers, as well as bolted joints and air frames in the aerospace industry.

AISI 4330V STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 4330V | 0.28-0.33 | 0.15-0.35 | 0.75-1.0 | ≤0.025 | ≤0.015 | 0.75-1.0 | 1.65-2.00 | 0.35-0.50 | 0.05-0.10 |

AISI 4330V STEEL FORGING

- Initial Forging Temperature:1150-1200℃

- Final Forging Temperature:>850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Holding Time:Ensure that the material is fully and evenly heated,and the holding time should not be too long or too short.

- Forging Ratio:above 4:1

- Post-Forging Treatment:According to our experience, 4330V steel has extremely high sensitivity to white spots, so dehydrogenation annealing after forging is a necessary heat treatment process.

AISI 4330V Steel Metallurgical Quality Technical Requirements

1. Macroscopic structure

| General Porosity(Grade) | Central Porosity(Grade) | Pattern Segregation(Grade) | General Spot Segregation(Grade) |

| ≤2.0 | ≤2.0 | ≤2.0 | not allowed |

2.Non-metallic Inclusions

| Non-metallic Inclusions | |||||||

| A | B | C | D | ||||

| Fine | Coarse | Fine | Coarse | Fine | Coarse | Fine | Coarse |

| Max 1.5 | Max 1.5 | Max 2.0 | Max 1.5 | Max 1.0 | Max 1.0 | Max 1.5 | Max 1.0 |

3.Gas content

| Hydrogen ,ppm | Oxygen,ppm | Nitrogen ,ppm |

| ≤2.0 | ≤20 | ≤80 |

AISI 4330V STEEL HEAT TREATMENT

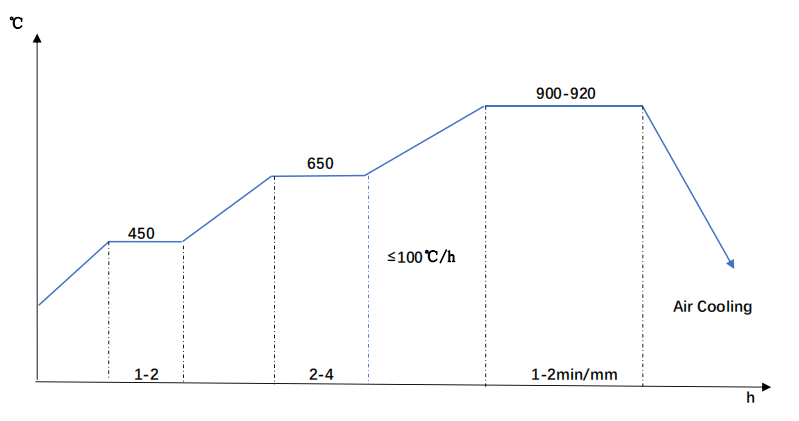

- Normalizing:900-920℃,Cool in air.

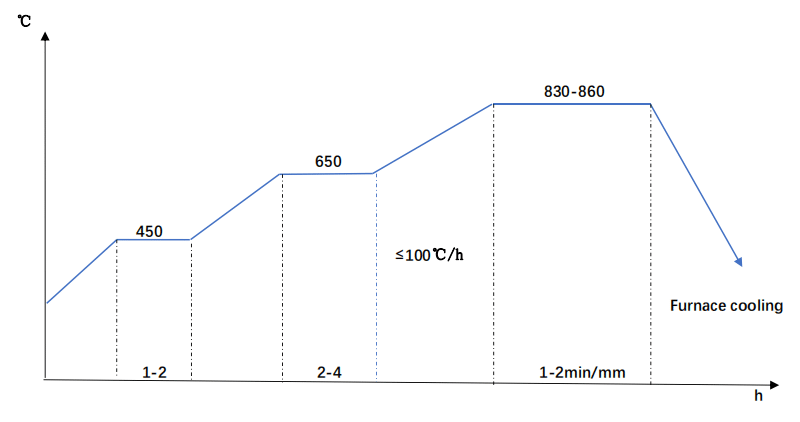

- Annealing:830-860℃,Cool in furnace,Hardness Max 241 HBW.

4330V Steel Normalizing Diagram

4330V Steel Annealing Diagram

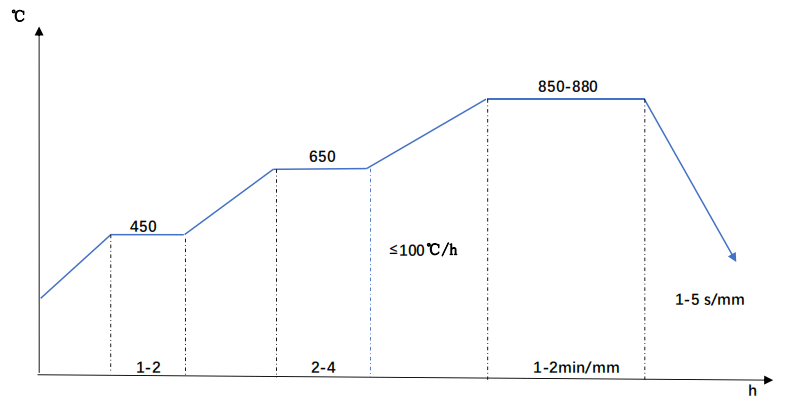

- Quenching: 850-880℃,Oil quench.

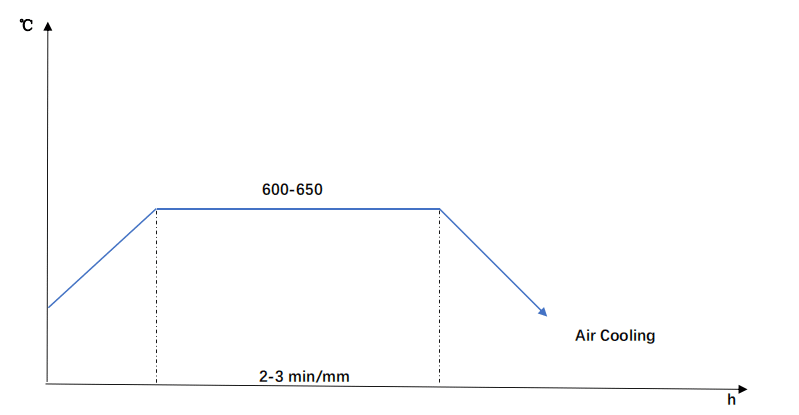

- Tempering:600-650°C, cool in still air.

4330V Steel Quenching Diagram

4330V Steel Tempering Diagram

4330V Steel Quenching&Tempering Mechanical Property

| Level | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V,+23℃ | Impact Charpy-V,-20℃ | Hardness,HRC |

| 135KSI | ≥1000Mpa | ≥931Mpa | ≥14% | ≥50% | ≥65 | ≥50 | 30-36HRC |

| 150KSI | ≥1104Mpa | ≥1035Mpa | ≥14% | ≥45% | ≥54 | ≥54 | 34-40HRC |

| 155KSI | ≥1138Mpa | ≥1069Mpa | ≥14% | ≥45% | ≥54 | ≥27 | 34-40HRC |

AISI 4330V STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ260mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled