AISI 4145/4145H steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.

AISI 4145 Steel is defined as Cr-Mo series alloy steel as per USA standard ASTM A29.Like AISI 4130 steel, it is widely used in the oil and gas industry.Compared with AISI 4140 steel, AISI 4145 has a higher carbon content, which means higher strength and hardenability.

AISI 4145 steel is usually used in the quenched and tempered condition, and can be used for oil drill collars, shafts, spindles, and high-load control wheels, bolts, studs, gears, etc.

AISI 4145 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

AISI 4145 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

AISI 4145 STEEL FORGING

- Initial Forging Temperature:1180℃

- Final Forging Temperature:850℃

- Forging Ratio:above 4:1

- Cooling Method After Forged: AISI 4145 Steel should be cooled as slowly as possible in sand after forged.

QUICK FAQS FOR AISI 4145 STEEL

Is AISI 4145 Steel For Oil Drill Collars?

AISI 4145 steel has good comprehensive mechanical properties and corrosion resistance after heat treatment, and is the most widely used medium-carbon low-alloy steel in the international petroleum industry.

Due to its good strength and toughness and resistance to H2S corrosion, AISI 4145 Steel can be used as a drill collar material in the process of oil exploitation, and also be used for the production of oil drill pipes. Especially for its excellent resistance to corrosion in oil and gas environments, AISI 4145 steel is also used in the production of petroleum pipelines.

Is AISI 4145 Steel Corrosion Resistant?

AISI 4145 steel is mainly used in the production of oil drill collars, and can also be used in the production of oil casing, which are used in corrosive environments in oil fields.

The good structure of AISI 4145 steel (tempered sorbite) can improve the corrosion resistance. In addition, the alloying element Cr can be dissolved in F, which can improve the corrosion resistance, and the Mo element also helps to improve the corrosion resistance.

Can AISI 4145 Steel be Welded?

Calculated from the composition of AISI 4145, its CE is about 0.85,and its weldability is very poor.When welding AISI 4145 steel, preheating before welding and post-welding heat treatment are mandatory. Strict welding process for AISI 4145 can ensure the reliability of welding.

What is AISI 4145H?

When add “H”,this means that AISI 4145 steel is required to ensure hardenability.In fact, there is no difference in composition between AISI 4145H and AISI 4145 steel.

What is AISI 4145H MOD?

MOD means Modify.Therefore, AISI 4145H MOD is an improvement on the basis of AISI 4145 steel, which may be due to changes in composition or more stringent performance requirements.

AISI 4145H MOD Drill Collar

AISI 4145 Steel Vs 50CrMo4 Steel

As a representative of medium carbon Cr-Mo series low alloy steel,AISI 4145 is derived from ASTM A29 American standard, while 50CrMo4 belongs to European standard EN10083.First of all, let’s take a look at their differences from their composition.please see the table below.

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo |

| ASTM A29 | 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| EN10083 | 50CrMo4 | 0.46-0.54 | ≤0.4 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.30 |

From the above table,the main difference between the elements is in C and Mn, and the other elements are generally very small.Due to these differences, 50CrMo4 steel is superior to AISI 4145 steel in terms of strength and hardenability,but its welding performance is relatively poor.

AISI 4145 steel is mainly used in the petroleum industry, such as drill collars, drill pipes, and petroleum pipelines.While 50CrMo4 is used for forgings that require higher strength or larger cross-section than 42CrMo4 steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, engine cylinders, 1200~2000m oil deep well drill pipe joints and fishing tools, etc.Sometimes 50CrMo4 steel can replace quenched and tempered steel with higher nickel content.

AISI 4145H STEEL PRODUCTION PROCESS

AISI 4145H steel adopts appropriate composition design and advanced production technology to obtain good mechanical properties, so that it can meet the performance requirements of 4145H steel in the process of oil drilling.

The production process of AISI 4145H steel:

Molten steel pretreatment →Converter→LF→RH→Continuous casting-continuous casting→Hot delivery→Heating→Hot rolling/Forging→Heat preservation→Straightening→Annealing→Grinding→Inspection→Delivery

In order to obtain a uniform and compact casting blank, in the molten steel smelting process, it undergoes magnesium-based powder spraying desulfurization treatment, stirring with inert gas, vacuum degassing treatment, and microalloying element V/Ti to treat the inclusions in the steel.

In the smelting process, attention should be paid to the matching of C and Cr, Mn, Mo and other elements. These means ensure that the alloying elements in the steel are uniform, and a more uniform ferrite structure can be obtained.

Controlled rolling and controlled cooling technology can help improve the mechanical properties of 4145H steel, make it have good mechanical properties, ensure the uniformity of hardness, and prepare for subsequent deep processing.

AISI 4145 STEEL HEAT TREATMENT

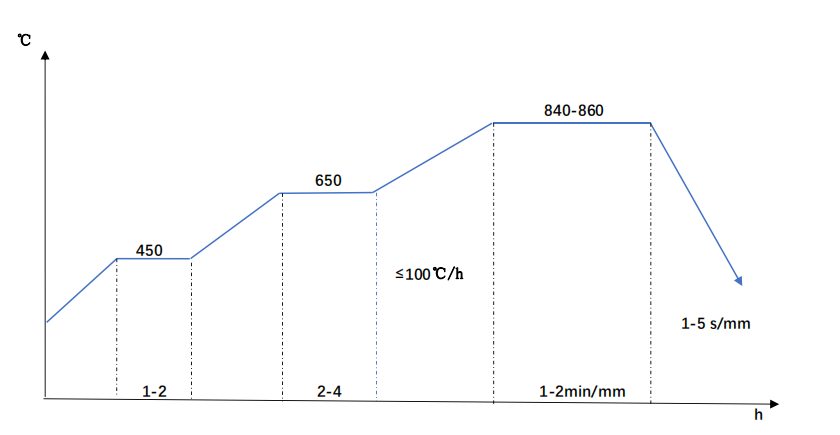

- AISI 4145 Steel Annealing

The annealing process of AISI 4145 steel is complete annealing, which can completely recrystallize the structure of the steel to eliminate the defects in the structure after the material is forged or rolled.

According to various studies and demonstrations, the best annealing temperature for AISI 4145 is 820℃,and it will be cooled with the furnace after holding for an appropriate time. The final structure in the steel is ferrite and pearlite,and its surface hardness is about 200HBW.

- AISI 4145 Steel Quenching & Tempering

AISI 4145 steel can obtain satisfactory overall performance through quenching and tempering heat treatment to meet the requirements of petroleum equipment.

Heating temperature and holding time are two important parts that affect the quality of quenching. The structure obtained after austenitization achieved by heating will affect the performance of the material after quenching.

For AISI 4145 steel, the appropriate quenching temperature is between 840-860ºC, and the holding time depends on the thickness of the material.

AISI 4145H Steel Quenching Diagram

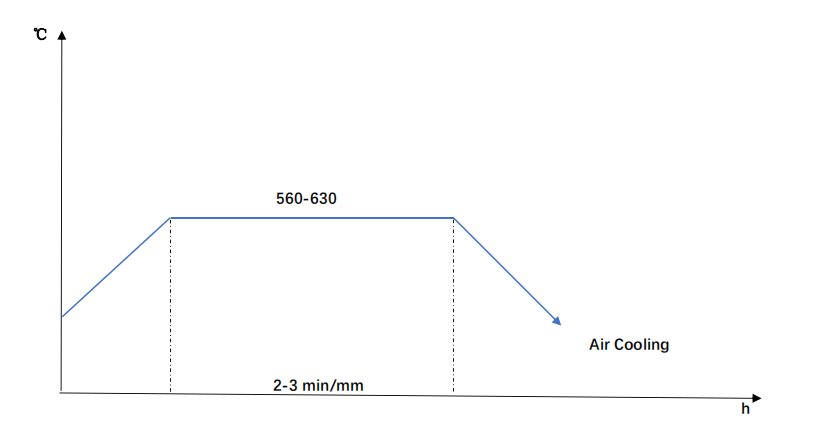

Tempering process should be followed after quenching immediately.When 4145 steel is used as drill collar steel, it needs to be tempered at a high temperature of 560-630ºC to obtain tempered sorbite, and finally obtain good comprehensive mechanical properties.

AISI 4145H Steel Tempering Diagram

- AISI 4145H Steel Mechanical Property in Q&T Condition

| Standard | Diameter mm | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction % | Charpy Impact J | Hardness HBW |

API SPEC 7-1 | 79.4-174.6 | ≥965 | ≥758 | ≥13 | ≥45 | ≥54 | 285-341 |

| 177.8-279.4 | ≥931 | ≥689 | ≥13 | ≥45 | ≥54 | 285-341 | |

| Actual Data | 280 | 966 | 866 | 19 | 57 | 70/74/74 | 295 |

AISI 4145H STEEL BUYING GUIDE

Usually when we talk about the oil and gas industry, the first thing that comes to mind is the representative steel grades of the Cr-Mo series, such as AISI 4140, AISI 4130, AISI 4340 and AISI 4145H. Indeed, they all play a heavy role in industrial applications.

The AISI 4145H we are talking about here, with its unparalleled performance characteristics, completely replaces the AISI 4140 steel used in the past and now is used as a special steel for oil drill collars.

From our guide, we’ll tell you everything you need to know about AISI 4145H as a steel for oil drill collars,which we believe will help you find high quality AISI 4145H steel more easily.

WHAT IS AISI 4145H STEEL GRADE DESIGNATION?

When it comes to U.S. steel grades, the American Iron and Steel Institute (A.I.S.I.) and the Society of Automotive Engineers (S.A.E.) are always the subject of conversation.Indeed, these two institutions are involved in the standardization of steel’s digital coding system,and they jointly designed a simple numbering system: Unified Numbering System,referred to as UNS.

As a means of identifying steels specified to hardenability band limits, the suffix letter “H” has been added to the conventional series number. In the Unified Numbering System (UNS),the”H” appears as a prefix. Here,unlike the UNS code G41450 of 4145 steel, the UNS code of 4145H steel is H41450.

After talking about the meaning of the letter H, the rest of the numbers are easy to understand. From the previous FAQ series, we can easily see that 4145H belongs to the 41XX series. Please refer to the table below for details.

Molybdenum Steel | 40XX | Mo 0.20-0.25% |

| 44XX | Mo 0.40-0.52% |

|

| Chromium-Molybdenum Steel | 41XX | Cr 0.50-0.95%, Mo 0.12-0.30% |

Nickel-Chromium-Molybdenum Steel | 43XX | Ni 1.82%, Cr 0.50-0.80%, Mo 0.25% |

| 47XX | Ni 1.05%, Cr 0.45%, Mo 0.20-0.35% | |

Nickel-Molybdenum Steel | 46XX | Ni 0.85-1.82%, Mo 0.20-0.25% |

| 48XX | Ni 3.50%, Mo 0.25% |

As can be seen from the above table, 4145H belongs to Cr-Mo series low alloy steel, and the meaning of the last two digits 45 in 4145H represent an average carbon content of 0.45%.

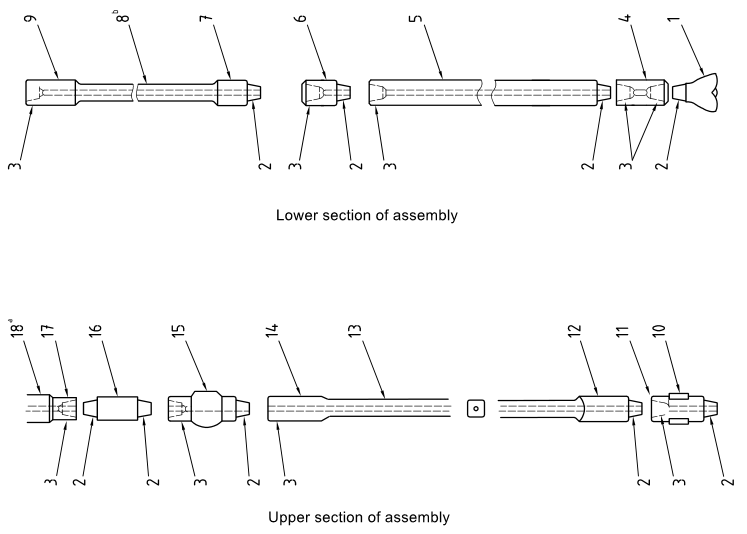

WHAT IS DRILL COLLAR?

The drill collar is the main component of the drill tool assembly which is installed between the drill pipe and the drill bit.During the drilling process, the drill collar is not only subjected to stress such as tension, compression, bending, and torsion, but also to the friction of the well wall and the wear and corrosion of oil, steam, mud and other media.

Typical Drill Stem Assembly

What is the function of the drill collar?

- Apply WOB to the drill bit

- Keep the drill pipe in tension and ensure the strength of the drill string working under compression

- Reduce the vibration, swing and beating of the drill bit,keep the drill bit works smoothly

- Control well deviation

What are the types of drill collars?

- Ordinary drill collar

Ordinary drill collars, also known as cylindrical drill collars or integral drill collars.The drill collar is usually made of ordinary alloy steel, the cross section of the pipe body is round inside and outside, and the connecting threads are machined at both ends.

- Spiral drill collar

The spiral drill collar is machined with three right-handed spiral grooves on the outer cylindrical surface of the round drill collar, and the weight is 4% less than that of the ordinary drill collar of the same size.

In directional drilling, the helical drill collar reduces the contact area with the well wall and can effectively prevent differential pressure sticking, so it has been widely used.

- Non-magnetic drill collar

Non-magnetic drill collars are mainly used for monitoring in the process of oil drilling, and their structure is the same as that of integral drill collars.

The material has good low magnetic permeability and good machinability. It is forged through strict chemical composition analysis, and the material has been tested for mechanical properties to ensure that the hardness, toughness, impact value and corrosion resistance meet the standards.

The future trend of drill collars

The oil and gas resources that can be easily exploited in the world have been exhausted. The newly discovered oil and gas fields have poor drilling conditions and increased drilling depths, which require higher requirements for the manufacture of drill collars.

At present, the development of new steel for oil drilling tools and the development of high-strength and high-toughness steel for oil drill collars have attracted more and more attention. While improving the mechanical properties, improving its resistance to hydrogen sulfide corrosion has important practical significance for prolonging the life of materials and reducing economic losses.

QUICK FAQS FOR AISI 4145H DRILL COLLAR

What are non-metallic inclusion requirements for AISI 4145H drill collars?

Non-metallic inclusions not only affect the purity of the steel, but also affect the performance of the material, especially reducing the plasticity and impact toughness of the material.

For AISI 4145H drill collars, the non-metallic inclusions must meet the following requirements

| Non-metallic Inclusions | |||||||

| A | B | C | D | ||||

| Fine | Coarse | Fine | Coarse | Fine | Coarse | Fine | Coarse |

| Max 2.0 | Max 1.5 | Max 2.0 | Max 1.5 | Max 2.0 | Max 1.5 | Max 2.0 | Max 1.5 |

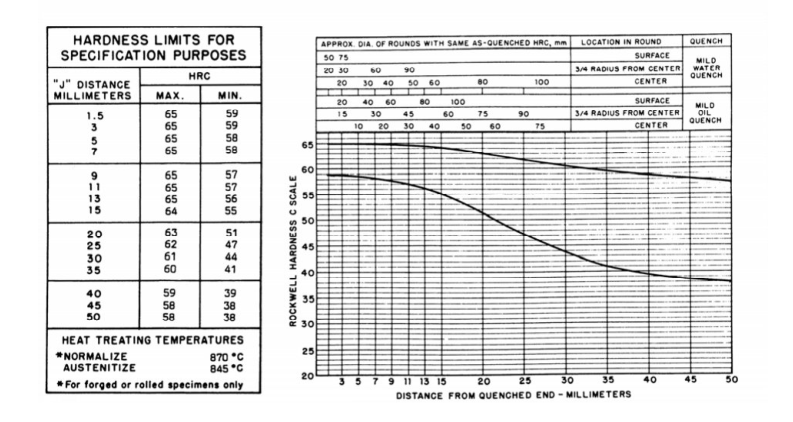

What are the requirements for the hardenability of AISI 4145H drill collars?

AISI 4145H drill collar has high requirements on hardness, strength and toughness. We can understand its performance through the hardenability curve. Generally speaking, the steel with high hardenability has high mechanical properties.

AISI 4145H Hardenability Curve

For AISI 4145H drill collars, the hardenability must meet the following requirements

Grade | End hardenability,HRC | ||

| J1.5 | J25 | J50 | |

| AISI 4145H | ≥56 | ≥50 | ≥50 |

| Normalizing:880-900℃,Quenching:860℃ | |||

What are macroscopic structure requirements for AISI 4145H drill collars?

The macroscopic structure mainly affects the compactness of the material, which in turn has a great influence on the processability and mechanical properties of the steel.For AISI 4145H drill collars, the macroscopic structure must meet the following requirements

| General Porosity(Grade) | Central Porosity(Grade) | Pattern Segregation(Grade) | General Spot Segregation(Grade) |

| ≤2.0 | ≤2.0 | ≤2.0 | not allowed |

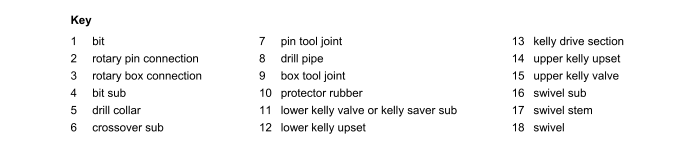

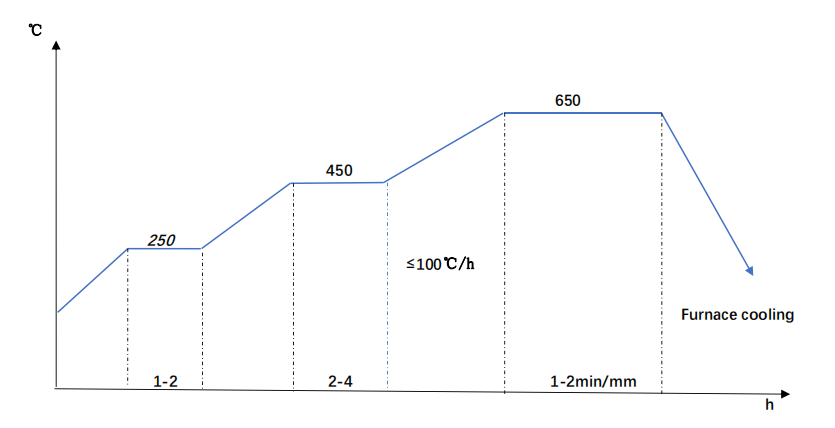

How to prevent white spots for AISI 4145H steel?

As a Cr-Mo series alloy steel, AISI 4145H has strong white spot sensitivity.In order to prevent the occurrence of white spots, we usually do a dehydrogenation heat treatment on the forged AISI 4145H steel immediately.The heat treatment curve is as follows

Why use AISI 4145H steel instead of AISI 4140 steel for drill collars?

AISI 4145H drill collar steel is produced according to American standards. As a medium carbon low alloy steel, it has certain similarities with AISI 4140 steel in terms of mechanical properties and stress corrosion.

Before the 1990s, AISI 4140 was mostly used, but 4140 was not satisfactory in terms of mechanical properties and resistance to hydrogen sulfide corrosion.

The good mechanical properties and hydrogen sulfide corrosion resistance of AISI 4145H steel have a significant impact on increasing its service life, reducing oilfield accidents, and reducing costs.

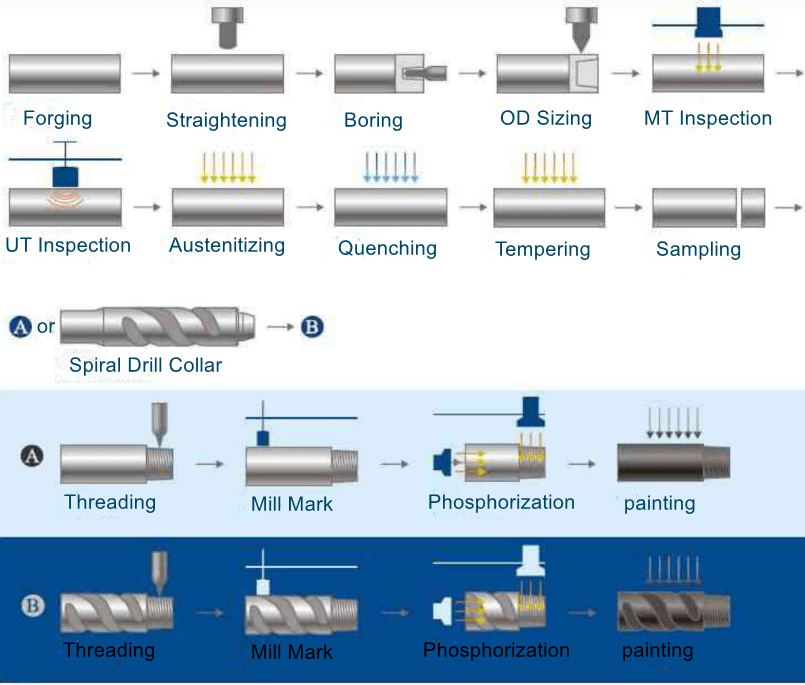

HOW TO MAKE HIGH QUALITY AISI 4145H DRILL COLLAR?

AISI 4145H steel has good comprehensive mechanical properties and corrosion resistance after heat treatment, and is the most widely used medium carbon low alloy steel in the petroleum industry.Due to its good strength, toughness and H2S corrosion resistance, AISI 4145H steel is widely used in drill collars and drill pipe materials in the process of oil production.

Due to the particularity of the material, the quality of drill collars made of AISI 4145H steel is difficult to satisfy. Therefore, we are faced with the question of how to manufacture high-quality AISI 4145H Drill Collars, then we will have a good discussion on this topic.

From the figure above, we can roughly see a production flow chart of Drill Collar,we will talk about a few important control points in the flow chart with AISI 4145H steel.

- Forging

Through strict forging process, forging high-quality 4145H material is an important prerequisite for manufacturing high-quality drill collars.

By strictly controlling the forging temperature, forging time and forging deformation, the original coarse dendrites and columnar grains in the ingots are transformed into equiaxed recrystallized structures with finer grains and uniform size,and it also makes the original segregation, looseness, pores, slag inclusion compact and close in the 4145H steel ingot.

For AISI 4145H Drill Collar,process as below

- Initial Forging Temperature:1150-1180℃

- Final Forging Temperature:above 850℃

- Forging Ratio:above 6:1

After forged, 4145H steel structure becomes more compact, which improves the plasticity and mechanical properties.

- Heat Treatment

As the most critical process, the heat treatment of AISI 4145H material directly determines whether high-quality drill collar tools can be manufactured.According to the requirements of API SPEC 7-1,AISI 4145H should be quenched(Q) and tempered(T) to achieve the performance requirements.

According to our rich experience, we will do normalizing heat treatment for AISI 4145H in advance, and then do Q&T to ensure that the material can perfectly meet the requirements.The specific requirements are shown in the table below.

| PROCESS | TEMPERATURE RANGE | TIME AT TEMPERATURE | COOLING |

| Normalizing | 860-890℃ | 0.5hr/inch of metal thickness | Air cool to room temperature |

| Quenching | 840-860℃ | 0.5hr/inch of metal thickness | Water or Oil/Polymer |

| Tempering | 560-630℃ | 0.5hr/inch of metal thickness | Air cool to room temperature |

- UT/MT Inspection

Ultrasonic inspection and magnetic particle inspection are both forms of non-destructive testing.For AISI 4145H drill collars, the best time for testing is after heat treatment. Ultrasonic testing mainly inspects internal defects, while magnetic particle testing is aimed at surface defects, mainly cracks detection.

UT and MT inspection are an important method to ensure maximum safety and reliability of AISI 4145H materials, which can be strictly implemented according to clause 11 of API SPEC 7-1.

- Sampling Testing

The performance of the AISI 4145H material sample ultimately represents the performance of the final product drill collar,so the detection of the sample is also a crucial part.

The principles of AISI 4145H sampling are implemented in accordance with clause 8.2.1 of API SPEC 7-1.After sampling, it is processed into test bars, and the subsequent processing can only be continued after the laboratory data is qualified.

WHERE CAN YOU BUY HIGH-QUALITY AISI 4145H STEEL?

Which manufacturer should you work with?Without a doubt, we will be your trusted partner.As a AISI 4145H forge manufacturer with over 10 years of manufacturing experience, no one is more familiar with it than us. We are capable of supplying high quality AISI 4145H material according to API SPEC7-1.

What We Supply For AISI 4145H Steel

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Free Sample of AISI 4145H Steel

Heat Treatment

- Normalized(+N)

- Annealed(+A)

- Quenched & Tempered(+QT)

Machining

Turning/Milling/Drilling/Peeling/Polishing