SAE 4130 steel is a low-alloy steel grade under the standards of the American Society of Automotive Engineers(SAE).

As a typical low carbon Cr-Mo series alloy steel, SAE 4130 steel is usually supplied in quenched and tempered state.After quenching and tempering, SAE 4130 steel has high strength, toughness, wear resistance and hardenability.

As a very practical material, the excellent performance of SAE 4130 steel makes it widely used in automobile, aviation, aerospace, metallurgy, machinery, oil and gas industries.

SAE 4130 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

What is the difference between ASTM 4130,AISI 4130 and SAE 4130?

First of all, let’s make a clear conclusion that there is no difference between 4130, SAE 4130, AISI 4130, and ASTM 4130.So the question is, why should it be expressed differently?

It turns out that each industry association in each country has its own admission standards, and so does the United States.SAE, AISI and ASTM represent the three major American associations, namely the Society of Automotive Engineers (SAE), the American Iron and Steel Institute (AISI), and the American Society for Testing and Materials (ASTM).

SAE 4130, AISI 4130, and ASTM 4130 only represent the standard grades under their respective industry associations, but they are still 4130 in essence.Therefore, in actual commercial activities, technicians will not deliberately distinguish them.

SAE 4130 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA | GB 3077:30CrMoA

Europe | EN10083 | EN10250:25CrMo4/1.7218

JAPAN | JIS G4105:SCM430

UK | BS970:708M25/708A25

SAE 4130 STEEL FORGING

- Initial Forging Temperature:1150-1180℃

- Final Forging Temperature: >850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Forging Ratio:above 4:1

- Post-Forging Treatment:According to our experience, for SAE 4130 steel with small section size, the general recommendation is to slowly cool in sand after forging.For SAE 4130 with large cross-sectional size or complex structure, we recommend annealing after forging due to its sensitivity to white spots.

SAE 4130 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of SAE 4130

- Ac1:757℃

- Ac3:807℃

- Ar1:693℃

- Ar3:763℃

- Ms:345℃

SAE 4130 Steel Normalizing

The normalizing heat treatment of SAE 4130 steel is often used in actual production.According to our experience, for workpieces with large cross-sections that require quenching and tempering heat treatment, prior normalization or non-normalization has a great influence on the final performance, especially when SAE 4130 steel is used in the oil and gas industry.

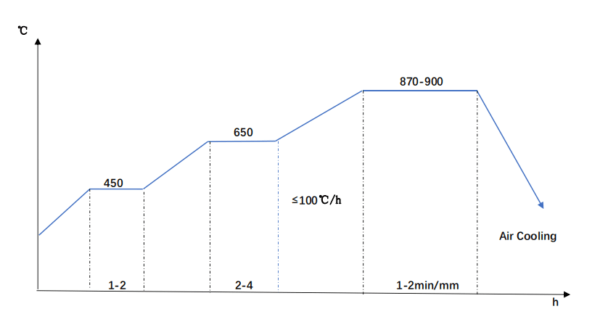

The normalizing temperature of SAE 4130 steel is generally 870-900°C. After uniform heating in sections, keep it for an appropriate time and air cool it to room temperature.

SAE 4130 Steel Normalizing Diagram

SAE 4130 Steel Normalizing Mechanical Property

| Normalizing temperature | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 870°C | ≥670Mpa | ≥435Mpa | ≥25.5% | ≥60% | ≥86 | 197HBW |

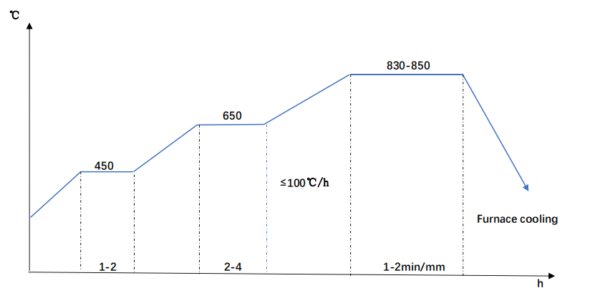

SAE 4130 Steel Annealing

The annealing temperature of SAE 4130 steel is controlled at 830-850°C. After homogenized heating, keep it for a sufficient time, and then cool it out of the furnace.It has been measured that the surface hardness of SAE 4130 steel after annealing is usually lower than 229HBW.

SAE 4130 Steel Annealing Diagram

SAE 4130 Steel Annealing Mechanical Property

| Annealing temperature | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 850ºC | ≥560Mpa | ≥360Mpa | ≥28.2% | ≥56% | ≥62 | 156HBW |

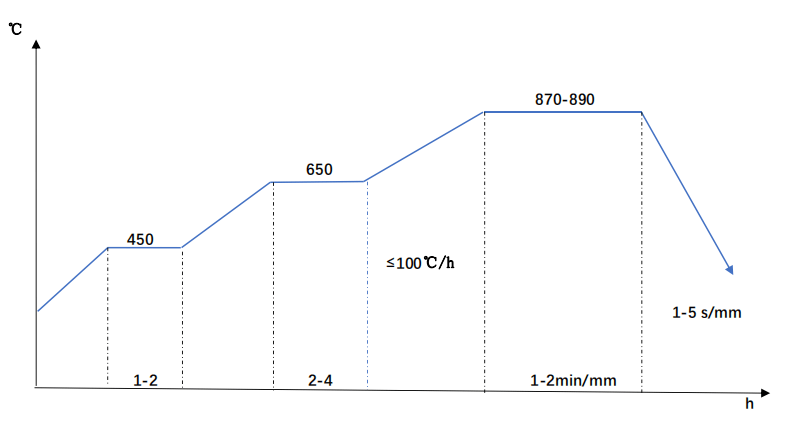

SAE 4130 Steel Quenching & Tempering(QT)

After quenching and tempering heat treatment, SAE 4130 steel has a wide application prospect due to its excellent performance.This requires us to strictly implement quenching and tempering process to ensure product quality.

Quench Temperature:870-890°C

Quench Medium: Water/Oil

Quenching Hardness:50-55HRC

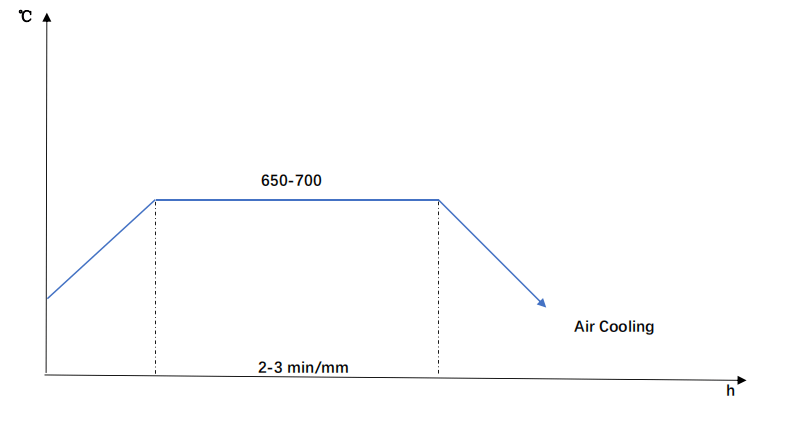

Tempering temperature:650-700℃

Tempering Hardness: 197-237HBW

SAE 4130 Steel Quenching Diagram

SAE 4130 Steel Tempering Diagram

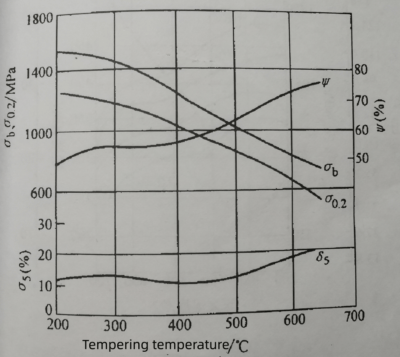

SAE 4130 Steel Tempering Temperature Vs Hardness

| Grade | Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC | |

| 4130 | 870ºC | >55 | 55 | 53 | 51 | 43 | 34 | 32 | 28 | 24 |

SAE 4130 steel Mechanical Properties Relationship Curve

SAE 4130 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ200mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled