AISI 4150 steel is a high-strength alloy structural steel, which has a higher carbon content than AISI 4140 steel in the Cr-Mo series medium carbon alloy steel.

AISI 4150 steel has high strength and toughness, good hardenability, and no obvious temper brittleness, but has white spot sensitivity during hot working.After normalizing or quenching and tempering, the machinability is good, but the plasticity is low during cold deformation, and the corresponding welding performance is poor.

AISI 4150 steel is suitable for forgings with higher strength or larger section than AISI 4140 steel, such as manufacturing large and medium-sized plastic molds that require certain strength and toughness.

AISI 4150 ALLOY STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

AISI 4150 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4150 | 0.48-0.53 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 50CrMo4/1.7228 | 0.46-0.54 | ≤0.4 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.30 |

AISI 4150 STEEL RELATED STANDARD & EQUIVALENT GRADE

China/GB 3077: 50CrMoA

Europe/EN10083: 50CrMo4/1.7228

UK/BS970:708M50

AISI 4150 STEEL FORGING

- Initial Forging Temperature:1200℃

- Final Forging Temperature:800℃

- Forging Ratio:above 4:1

- Post-Forging Treatment: AISI 4150 Steel should be cooled as slowly as possible in sand after forged.As a white point sensitive steel,the recommended practice is to do hydrogen elimination heat treatment immediately after forging.

AISI 4150 STEEL HEAT TREATMENT

- Normalizing: 850-880°C,cool in air

- Annealing: 800-840℃,cool in furnace

AISI4150 Steel Mechanical Properties in Normalizing and Annealing Conditon

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness | |

| Normalizing | 1115Mpa | 735Mpa | 11.7% | 31% | 12 | 321HBW |

| Annealing | 730Mpa | 380Mpa | 20.2% | 40% | 25 | 197HBW |

- AISI 4150 Steel Quenching & Tempering(Q&T)

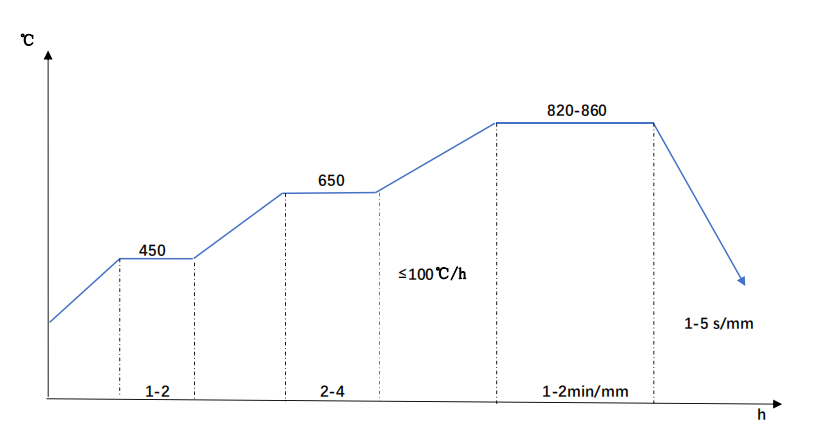

For Cr-Mo alloy steel, the performance of its material is mainly achieved by quenching and tempering.For example, AISI 4140 steel,AISI 4130 steel,while AISI 4150 steel, which is far stronger than AISI 4140 steel,ometimes can replace Ni series alloy steel in the applications.

For AISI 4150 steel,the suitable quenching temperature is 820-860ºC with quench medium oil.

AISI 4150 Steel Quenching Diagram

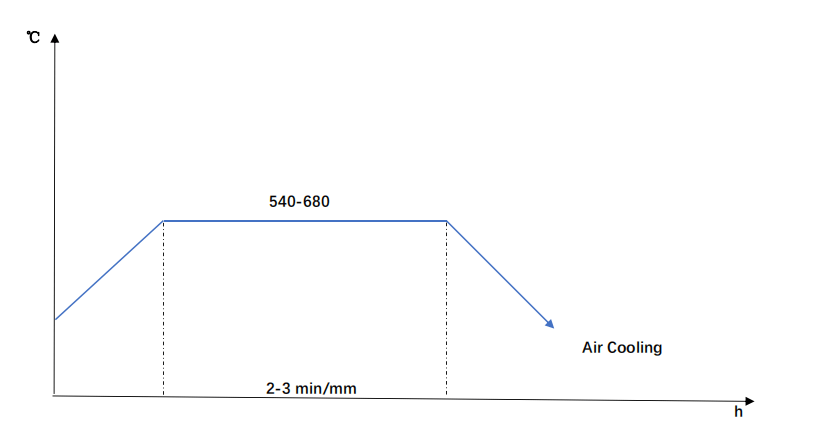

Tempering process for AISI 9840 steel should be followed after quenching immediately.The recommended tempering temperature is generally between 540-680°C

AISI 4150 Steel Tempering Diagram

AISI 4150 Steel Mechanical Property with Quenched and Tempered Condition

| Quenching Temperature | Quenching Medium | Tempering Temperature | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction % | Charpy Impact J |

| 840ºC | Oil | 560ºC | ≥1130 | ≥930 | ≥11 | ≥45 | ≥48 |

AISI 4150 Forged Flat steel with Q & T condition