20MnCr5 Steel ,also refers to DIN 1.7147 steel as per European standard EN10084.As the representative steel of the Chromium-Manganese series of case hardening steel,it has high strength and toughness.After quenching, the deformation is small and has good hardenability and low temperature toughness.20MnCr5 has relatively good machinability, but it is poor in welding performance.

20MnCr5/DIN 1.7147 Steel is usually used after carburizing and quenching or quenching & tempering.It is generally used for the manufacture and heavy-duty of large cross-section quenched and tempered parts and small cross-section carburized parts,also be used to manufacture medium and small parts with medium load and low impact,such as gears,shafts,friction wheels of variable speed equipment, worms, The sleeve of the governor,etc.

CHEMICAL COMPOSITION AS PER EN10084

| Grade | C | Si | Mn | P | S | Cr |

| 20MnCr5/1.7147 | 0.17-0.22 | ≤ 0.4 | 1.1-1.4 | ≤ 0.025 | ≤ 0.035 | 1.0-1.3 |

20MNCR5/DIN 1.7147 RELATED STANDARD & EQUIVALENT GRADE

| China/GB 3077 | USA/ASTM A29 | Japan/JIS G4053 | France/AFNOR NF A 35-551 | Germany/DIN 17210 |

| 20CrMn | 5120 | SMnC420 | 20MC5 | 20MnCr5 |

20MNCR5 /DIN 1.7147 STEEL HEAT TREATMENT

| Normalizing,°C | Annealing,°C | Carburizing,°C | Core Hardening,°C | Case Hardening,°C | Tempering,°C |

| 880-920 | 840-860 | 880-980 | 860-900 | 780-820 | 150-200 |

20MNCR5 /DIN 1.7147 MECHANICAL PROPERTY

- Annealed Condition

| Tensile Strength,Mpa | Yield Strength,Mpa | Elongation,% | Charpy Impact, J | Brinell Hardness,HB |

| 500-650 | ≥ 300 | ≥ 20 | ≥ 50 | ≤187 |

- Quenched and Tempered Condition

| Tensile Strength,Mpa | Yield Strength,Mpa | Elongation,% | Reduction of Area,% | Charpy Impact, J |

| ≥930 | ≥735 | ≥10 | ≥45 | ≥47 |

- Hardenability Limits

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 |

| HRC Min | 41 | 39 | 36 | 33 | 30 | 28 | 26 | 25 | 23 | 21 | – | – | – |

| HRC Max | 49 | 49 | 48 | 46 | 43 | 42 | 41 | 39 | 37 | 35 | 34 | 33 | 32 |

20MNCR5/DIN 1.7147 STEEL SUPPLY FORM & SIZE

Hot Forged Products

- Round : Dia.80 – 1,000mm

- Flat / Square : Thickness Max.800mm

- Rings,Tubes,Shafts, Rollers, Blocks: Customized or According to Drawing

Hot Rolled Products

- Round : Dia.14 – 280mm with Annealed Condition,UT quality assurance

- Other Shapes:Customized

20MNCR5/DIN 1.7147 STEEL-THE ULTIMATE FAQ BUYING GUIDE

There are many kinds of materials for gear applications in the market. For 20MnCr5 steel, as a common Cr-Mn series gear material, how much do you know about it?If you are interested, congratulations, you have come to the right place.

Through our specific guidance, we will fully describe the characteristics of 20MnCr5 steel,so as to further help you understand and use it.In addition, good ideas will be provided to help you identify other types of steel.

WHAT IS 20MNCR5 STEEL?

20MnCr5 Steel, also refers to DIN 1.7147 steel, as a representative of Cr-Mn series in case hardening steel,is included in the Germany Standard DIN 17210 and European standard EN10084.

So at this point, do we really understand the meaning of the numbers and letters in the 20MnCr5 grade?

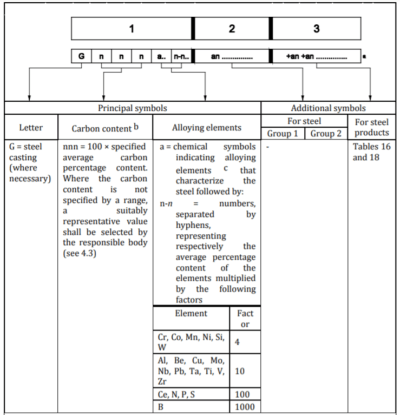

We can see the below Table 13 from EN10027 Standard:Designation systems for steels.

Key

1 = Principal symbols

2 = Additional symbols for steel

3 = Additional symbols for steel products

a n = numerical characters, a = alpha characters, an = alphanumeric characters.

b To distinguish between two similar steel grades, the number indicating carbon content may be increased by 1.

c The sequence of symbols shall be in decreasing order of the values of the average percentage content; where the values of contents are the same for two or more elements, the corresponding symbols shall be indicated in alphabetical order.

From the above rules,we can clearly know that ’20’ means the average carbon content,value 0.2%.This is consistent with the carbon content represented by the last two digits of the American label number. For example, AISI 5120, 20 means 0.2% carbon content.While the average content of Mn and Cr is the same, each is 5/4=1.25%

WHAT ARE CHARACTERISTICS OF CASE HARDENING STEEL?

Literally, Case Hardening,it means to increase the hardness of the metal surface through physical or chemical methods.So, what are the characteristics of case-hardened steel? We summarized a few points about the grades in EN10084.

- Low Carbon Content

From the EN10084 standard,we can see that whether it is carbon steel or alloy steel, their carbon content is obviously below 0.3%.Why is this?This is because steel with low carbon content tends to have low hardness, so it is necessary to increase the hardness.

- High Surface Hardness & Good Wear Resistance

After the material is carburized, nitrided or surface quenched, a hardened layer will be obtained on the surface to ensure that the surface of the material has a sufficiently high hardness.With the increase in hardness, the wear resistance of the material will also be greatly improved.

- Good Core Toughness & Stable Impact Resistance

There is a reason for surface hardening the material instead of trying to harden the entire metal object. If the core is also hardened, the material will become brittle and hard, unable to withstand the impact load and eventually lead to fracture.In summary, this requires the case hardened steel have good flexibility and impact resistance in the core.

QUICK FAQS FOR 20MNCR5/1.7147 STEEL

Is 20MnCr5 Gear Steel?

Yes,20MnCr5 steel, as a Cr-Mn series case hardening steel,is widely used to manufacture small and medium-sized parts with medium load and low impact after carburizing, such as gears, which is one of its most important applications.

What is 20MnCrS5 Steel?

20MnCrS5,all elements are the same as 20MnCr5, except for the S element.Why do we need to change the S element? Isn’t it a harmful element?It turns out that proper control of the S element can significantly improve the cutting performance of the material, which is desirable.

| Grade | C | Si | Mn | P | S | Cr |

| 20MnCrS5/1.7149 | 0.17-0.22 | ≤ 0.4 | 1.1-1.4 | ≤ 0.025 | 0.02-0.04 | 1.0-1.3 |

Is 20MnCr5 Steel Easy to Machine?

According to experience, materials with high Mn are generally difficult to process.After annealing,20MnCr5 is relatively easy to process.But if it is quenched, 20MnCr5 steel becomes very hard, and conventional tools are not suitable for processing this type of steel.

How Hard is 20MnCr5 Steel?

After annealing or normalizing, the hardness of 20MnCr5 steel is generally around 200HB, which may not reach the application level first.But after surface hardening, the hardness can reach upto 60HRC, and the core is about 40HRC,this has very good application prospects.

20MNCR5 STEEL VS 16MNCR5 STEEL

Just look at these two grades 20MnCr5 and 16MnCr5, you know that they should be very close. But what’s the specific difference, let’s discuss it in detail next.

- Chemical Composition

| Grade | C | Si | Mn | P | S | Cr |

| 20MnCr5/1.7147 | 0.17-0.22 | ≤ 0.4 | 1.1-1.4 | ≤ 0.025 | ≤ 0.035 | 1.0-1.3 |

| 16MnCr5/1.7131 | 0.14-0.19 | ≤ 0.4 | 1.0-1.3 | ≤ 0.025 | ≤ 0.035 | 0.8-1.1 |

From the table,we can see that the difference in chemical composition between 20MnCr5 and 16MnCr5 is not obvious.We can regard 20MnCr5 as an upgraded version of 16MnCr5.Through technical adjustments, we can also share these two grades.

| Grade | C | Si | Mn | P | S | Cr |

| 16/20MnCr5 | 0.17-0.19 | ≤ 0.4 | 1.1-1.3 | ≤ 0.025 | ≤ 0.035 | 1.0-1.1 |

- Hardenability Limits

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | |

20MnCr5 | HRC Min | 41 | 39 | 36 | 33 | 30 | 28 | 26 | 25 | 23 | 21 | – | – | – |

| HRC Max | 49 | 49 | 48 | 46 | 43 | 42 | 41 | 39 | 37 | 35 | 34 | 33 | 32 | |

16MnCr5 | HRC Min | 39 | 36 | 31 | 28 | 24 | 21 | – | – | – | – | – | – | – |

| HRC Max | 47 | 46 | 44 | 41 | 39 | 37 | 35 | 33 | 31 | 30 | 29 | 28 | 27 | |

From the above table,We can see the gap between 16MnCr5 and 20MnCr5 in the end quenching test.As an upgraded version of 16MnCr5, the hardenability of 20MnCr5 is significantly better than 16MnCr5.

- Hardness requirements for delivery conditions

| Conditions | 20MnCr5 | 16MnCr5 |

| Treated to improve shearability(+S) | ≤255HBW | - |

| Soft annealed(+A) | ≤217HBW | ≤207HBW |

| Treated to Hardness range(+TH) | 170-217HBW | 156-207HBW |

| Treated to ferrite-pearlite structure and hardness range(+FP) | 152-201HBW | 140-187HBW |

| Normalized(+N) | 140-201HBW | 138-187HBW |

Based on the above points, 20MnCr5 is better than 16MnCr5 in terms of hardenability, surface hardness after carburization, wear resistance, and low-temperature impact toughness. But it does not mean that we must choose 20MnCr5, we need to comprehensively consider the cost performance according to the requirements of the application.

WHERE TO BUY GOOD QUALITY 20MNCR5 STEEL?

We believe that you can buy 20MnCr5 steel in any country, the most common one is from the West like the Americas or Europe.But believe me, choosing a Chinese supplier can help you get the best quality and the most beautiful price.

16/20MnCr(S)5 Forged Blocks With Annealed Conditon

The quality of Halden steel can be guaranteed just like the high hardness of 20MnCr5 after carburizing.Here, you can also professionally customize your 20MnCr5 steel according to your business needs,no matter what type of shapes, forms, and sizes.

In addition to 20MnCr5 or 1.7417 steel,you can also rely on us to provide you with assistance in other steel grades and grades, such as AISI 4140 alloy steel, AISI 1045 carbon steel, AISI 4340 alloy steel,34CrNiMo6 /DIN 1.6582 steel and so on!

Trust us, when you choose Halden Steel as your manufacturer, you and your business will benefit for life.