4140 steel, as one of the representative steel grades of American Standard Cr-Mo series low alloy steel, is widely used in many industries because of its excellent toughness, wear resistance, impact resistance and high fatigue strength.

Relying on the company’s mature process technology and complete production and testing equipment, as one of the company’s main products,we can not only manufacture and supply black surface materials for 4140 steel, but also perform quenching and tempering heat treatment, straightening, peeling, grinding, polishing, chamfering and cutting off and other supporting services for 4140 silver bright steel according to customer requirements.

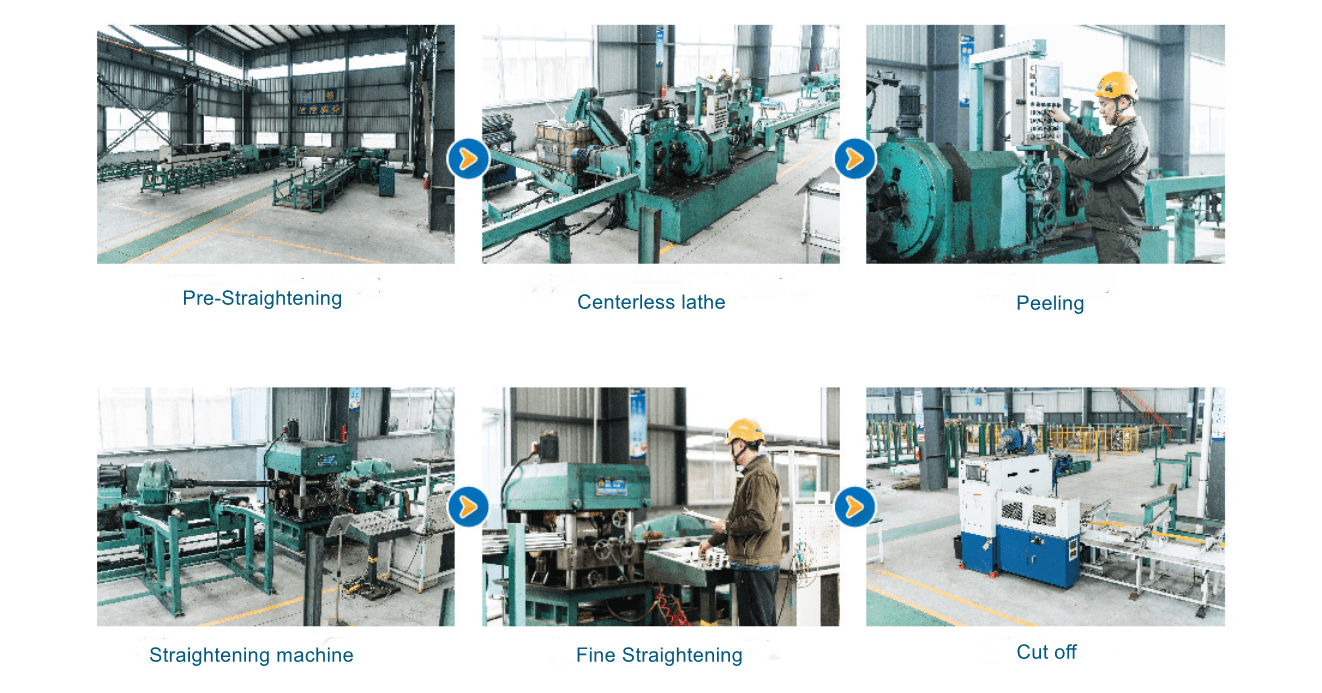

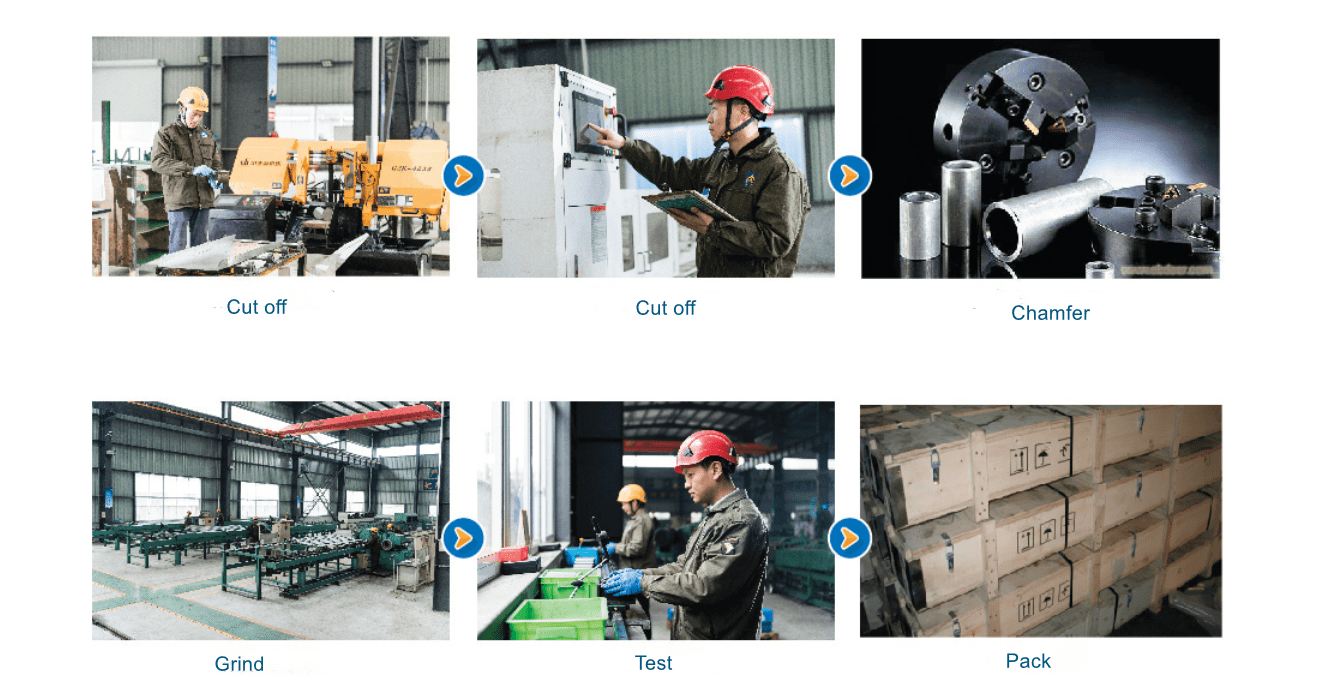

4140 STEEL BRIGHT BAR PRODUCTION PROCESS

With a number of automatic intermediate frequency quenching lines, which can do quenching and tempering heat treatment for round steel with a diameter of 16-125mm.

Equipped with 80 type Straightener,60/40 type Straightener, 80/40 type Centerless lathe,83 type centerless grinder,polishing machines,circular saw,band saw and chamfering machines.

Relying on mature equipment and rich experience, a complete one-stop production process from quenching and tempering to final product delivery has been formed.

Intermediate Frequency Quenching==>Tempering==>Pre-Straightening==>Peeling==>Fine Straightening==>Cut Off==>Chamfering==>Grinding==>Final Testing==>Packing

With ISO-9001 international certification, our product quality is highly praised by domestic and foreign customers, and we also look forward to becoming a strategic partner in your supply chain.

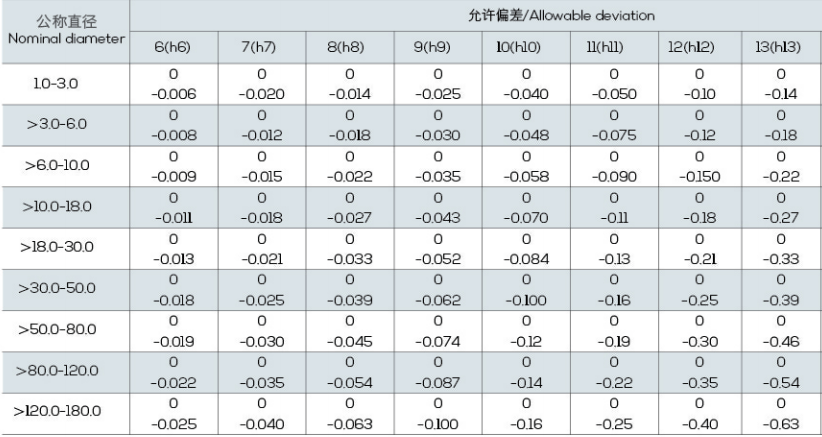

4140 STEEL BRIGHT BAR SILVER STANDARD

- 4140 Steel Bright Bar Straightness

| Category | Code | Straightness ,mm/m |

| Peeling Material | SF | ≤1 |

| Polished Material | SP | ≤2 |

| Polishing Material | SB | ≤1 |

- 4140 Steel Bright Bar Surface Roughness

| Category | Code | Roughness,Ra/μm |

| Peeling Material | SF | ≤3.0 |

| Polished Material | SP | ≤5.0 |

| Polishing Material | SB | ≤0.6 |

- 4140 Steel Bright Bar Allowable Diameter Tolerance

4140 STEEL BRIGHT BAR CUT-OFF STANDARD

- Length Management

Fully automatic import cutting equipment is adopted to ensure tolerance and verticality.

- Weight Management

There are corresponding electronic scales and weights for different weights, and then unified management according to customer requirements

Cut -Off Standard

- Cutting Tolerance:+/-0.05-0.07mm

- Vertical Tolerance:+/-0.05-0.07mm

- Surface Finish Roughness:Ra≤3.2μm

- Roundness:+/-0.1 – +/-0.2mm

- Straighteness: +/-5mm( in 6m length)

4140 STEEL BRIGHT BAR QUALITY INSPECTION

- Dimensional inspection

- Hardness check

- Mechanical property testing

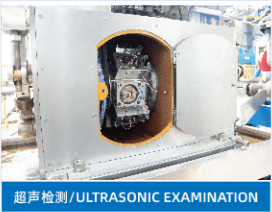

- Automatic flaw detection system

14-Channels Ultrasonic Testing

- Four probes in 4 Channels:Detecting longitudinal cracks inside and outside the bar in two directions

- Six probes in 6 Channels:Detecting transverse cracks inside and outside the bars

- Four probes in 4 Channels:Detecting internal defects in the bars

3-Channels Eddy Current Testing

Detection method of probe rotation,Detecting surface and near surface defects.

Detection diameter:Ф17mm~Ф80mm

Detection length:3-9m

Straightness:≤1.5mm/m

Detect applicable materials:High strength steel,Carbon tool steel,Carbon structural steel,Alloy structural steel,Tool steel,Spring steel,Bearing steel,High-speed steel,Stainless steel

Defect detection capability

The following comparative defects can be detected in the online state.

Center cross hole:Ф0.8x15mm

2mm horizontal hole under the skin:Ф0.5×12.7mm

Surface groove:depth x width x length 0.1×0.1x10mm

TECHNICAL ADVANTAGES FOR 4140 STEEL BRIGHT STEEL BAR

- Heat Treatment

Heat treatment(medium frequency quenching+roller furnace tempering)+stress relief tempering after straightening, according to the needs of customers, it can be processed into silver briqht material with the hiqhest precision of qrade H8,uniform structure,moderate hardness, controlled dimensional tolerance,no decarburization and no defects on the surface especially suitable for shafts,bearings and rings,etc.

- Physical & Chemical Properties

With good metallographic structure and uniform hardness, it is conducive to the quality stability of subsequent high-frequency quenching. with high dimensional accuracy, smooth surface and no defects,it can greatly improve machining efficiency and reduce material loss, which has been widely used by mainstream manufacturers.

- Post Process

After heat treatment,the silver bright material is processed by straightening,peeling,fine straightening,centerless grinding,flaw detection, etc,which can save the previous process of parts processing.

It greatly reduces the production cost and improves the production efficiency.At present,the silver bright material after pre heat treatment has been widely used in all machining industries as the fine material instead of the original black material.

- Technical Service

We provides material heat treatment technical services, after-sales technical guidance services and technical research and development services for our customers.

BECOME YOUR STRATEGIC PARTNER IN YOUR SUPPLY CHAIN

- 1000+tons daily stock for 4140 steel round bar

- Hot rolled/QT(pre hardened) condition for 5 days deliver available

- Bright steel with QT condition for 10 days deliver available

- Cold drawn steel for 20 days deliver available

- Cut to length service available