As the earliest high-chromium stainless steel, AISI 420 steel has better cost performance than normal stainless steel.In addition, it also has good wear resistance and corrosion resistance.Compared with AISI 410 steel,AISI 420 is also a martensitic stainless steel with magnetic properties and can be seen as a high carbon version of AISI 410 which can provide higher strength.

Therefore, AISI 420 has been more widely used in the case of low requirements for corrosion resistance.AISI 420 steel stainless steel is suitable for all kinds of precision machinery, bearings, electrical, equipment, instruments, meters, transportation tools, household appliances, etc. It is mostly used to manufacture parts that are resistant to atmospheric, water vapor, water and oxidative acid corrosion.

AISI 420/S42000 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr |

| 420/S42000 | ≥0.15 | ≤1.0 | ≤1.0 | ≤ 0.04 | ≤ 0.03 | 12-14 |

AISI 420 STEEL EQUIVALENT GRADE

China:20Cr13/2Cr13

Europe:X20Cr13/DIN 1.4021

Japan:SUS420J1

AISI 420/S42000 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.75 | |

| Melting point,℃ | 1470-1510 | |

| Specific heat capacity,(0~100℃),kj/(kg.k) | 0.46 | |

Thermal conductivity W/(m.K) | 100℃ | 500℃ |

| 22.2 | 26.4 | |

Linear expansion coefficient,10^-6/k | 0~100℃ | 0~500℃ |

| 10.3 | 12.2 | |

| Resistivity(20℃),Ω.mm2/m | 0.55 | |

| Longitudinal modulus of elasticity (20℃),kN/mm2 | 200 | |

| Magnetic | Magnetic | |

AISI 420 STEEL HEAT TREATMENT CRITICAL TEMPERATURE

- Ac1:820℃

- Ac3:950℃

- Ar1:780℃

- Ms:300-350℃

AISI 420 STEEL FORGING

- Forging process characteristics

In the process of heating and cooling, AISI 420 martensitic stainless steel undergoes allotropic transformation. For this type of steel, there is no special requirement for the amount of deformation in the last forging.

When AISI 420 martensitic stainless steel is heated for forging, it is necessary to avoid the formation of δ-ferrite, because the appearance of ferrite will cause cracks in the forging,and it is also necessary to avoid overheating caused by excessive heating of the metal. Surface decarburization of forgings can cause excessive ferrite formation,so surface decarburization should be minimized.

AISI 420 martensitic stainless steel is prone to cracking after forging. This is because martensite and carbide structures will appear during air cooling after forging, resulting in large internal stress, so it should be cooled slowly after forging,generally slow cooling in the sand pit at about 200 °C,and annealing should be carried out in time after being taken out from the sand pit to prevent breakage.

- Forging temperature range

The initial forging temperature of martensitic stainless steel is affected by the formation temperature of high-temperature ferrite and the state of ferrite. For example, when the ferrite is in a band shape, cracks are easy to occur,while when the ferrite is in a fine spherical shape, the plasticity is significantly improved.

For AISI 420 steel,the initial forging temperature is generally 1100-1150℃,and the final forging temperature varies with the carbon content, generally 850-900℃,which should be higher than the allotrope transformation temperature of steel.

AISI 420/S42000 STEEL HEAT TREATMENT

- Interprocess(subcritical temperature) Annealing:675-760℃,Hardness:94-97HRB

- Recrystallization(complete) Annealing:hold sufficient time at 830-850℃,furnace cooling to 790°C, continuous cooling to 595°C at a rate of 15-20°C/h, and air cooling to room temperature.Hardness:86-95HRB

- Isothermal Annealing:Heating to 830-850℃,Holding 2 hours at temperature 705℃.Hardness<95HRB.

- Hardening:1000-1050℃,water/oil quench,Hardness:47-49HRC

- Tempering:600-750℃,fast cooling,Hardness:25-40HRC

AISI 420 Tempering Temperature Vs Hardness

- Tempered at 300℃, Oil-cooled, Hardness is about 48HRC

- Tempered at 400℃, Oil-cooled, Hardness is about 46HRC

- Tempered at 500℃, Oil-cooled, Hardness is about 45HRC

- Tempered at 550℃, Oil-cooled, Hardness is about 42HRC

- Tempered at 600℃, Oil-cooled, Hardness is about 37HRC

- Tempered at 650℃, Oil-cooled, Hardness is about 28HRC

- Tempered at 700℃, Oil-cooled, Hardness is about 240HB

- Tempered at 750℃, Oil-cooled, Hardness is about 210HB

AISI 420/S42000 Steel Mechanical Property with Quenched and Tempered Condition

Quenching Temperature:1000-1050℃

Quenching Medium:Water/oil

Tempering Temperature:660-770℃

Cooling Medium:oil/water/air

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction of Area,% | Impact Charpy-V,J | Hardness,HBW |

| ≥600 | ≥450 | ≥16 | ≥55 | ≥80 | ≥192 |

AISI 420/S42000 STEEL APPLICATION

As a martensitic stainless steel, the main properties of AISI 420 steel are similar to those of AISI 410 steel. Due to the higher carbon content, its strength and hardness are higher than that of 410 steel, while its toughness and corrosion resistance are slightly lower.

AISI 420 steel is mainly used in the manufacture of parts subject to high stress loads, such as steam turbine blades, thermal oil pumps, shafts and bushings, impellers, hydraulic press valve plates, etc.It can also be used in the paper industry, medical equipment industry and daily consumer fields, such as knives, tableware, etc.

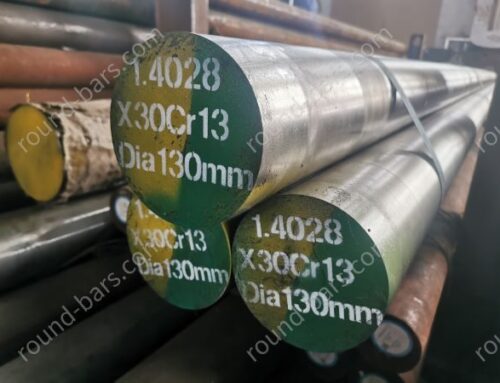

AISI 420/S42000 STEEL SUPPLY FORM & SIZE & TOLERANCE

Round bar: Dia 16-200mm As rolled

Round bar: Dia 80-400mm As forged

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Other shapes for AISI 420 Steel,such as plate,flat,shaft,ring,tube can be customized.