AISI 1020 steel is a low hardenability and low tensile carbon steel which has a nominal 0.22%C and 0.55%Mn. It has excellent weldability,good machinability ,and high ductility with Brinell hardness of 119 – 235 and tensile strength of 410-790 MPa. It is normally used in turned and polished or cold drawn condition. Due to its low carbon content, it is resistant to induction hardening or flame hardening. Due to lack of alloying elements, it will not respond to nitriding. However, carburization is possible in order to obtain case hardness more than Rc65 for smaller sections that reduces with an increase in section size. Core strength will remain as it has been supplied for all the sections. Alternatively, carbon nitriding can be performed, offering certain benefits over standard carburizing.

1.AISI 1020 steel Supply Form & Size &Tolerance

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1000 | 3000-10000 |

| Square bar | 100 x 100-600x600 | 3000-6000 |

Flat bar/Blcoks | Thickness :120-800 | 2000-6000 |

| Width:120-1500 |

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition & Related Specifications

| Grade | C | Si | Mn | P | S |

| 1020 | 0.17-0.23 | ≤ 0.4 | 0.30-0.60 | ≤ 0.04 | ≤ 0.05 |

| Germany | UK | China | Japan |

| C22/1.0402 | EN3/070M20 | 20# | S20C |

3.Physical Property

Modulus of elasticity [10^3x N/mm2]: 210

Density [g/cm^3]: 7.70

Thermal conductivity [W/m.K]: 51.9

Electric resistivity [Ohm mm^2/m]: 0.11

Specific heat capacity[J/g.K]: 0.46

4. AISI 1020 steel Mechanical Property

| Diameter mm | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of area % | Condition |

| ≤ 16 | 500 - 650 | ≥ 340 | ≥20 | ≥50 | Quenched and tempered |

| >16 – 40 | 470 - 620 | ≥290 | ≥22 | ≥50 | |

| ≤ 16 | ≥430 | ≥240 | ≥24 | Normalised |

|

| >16 – 100 | ≥410 | ≥3210 | ≥25 |

5.AISI 1020 steel Forging

Forging temperature:950-1200℃,air cooling after forging.

6.AISI 1020 Heat Treatment

Normalising:880 – 920°C,air cooling

Soft annealing:680 – 710°C,furnace cooling

Hardening:860 – 900°C,water quench

Tempering:550 – 660°C,air cooling

7.Application

AISI 1020 steel can be largely utilized in all industrial sectors in order to enhance weldability or machinability properties. It is used in a variety of applications due to its cold drawn or turned and polished finish property.

AISI 1020 steel is also used in case hardened condition,and it finds use in the following components:

- axles

- general engineering parts and components

- machinery parts

- shafts

- camshafts

- gudgon pins

- ratchets

- light duty gears

- worm gears

- spindles

- cold headed bolts

- automotive components

AISI 1020 CARBON STEEL – THE COMPLETE FAQ GUIDE

While you are looking for AISI 1020 carbon steel for demand,it seems simple to find this one of the most common steel from the market,but also it is a challenge work to source top level quality of AISI 1020 steel between different suppliers.

Reading our guide,you will get everything you need to know about 1020 steel,and following are the queries that you might have in your mind regarding the 1020 steel before buying.

WHAT DOES AISI 1020 MEAN?

The AISI stands for American Iron and Steel Institute. It is a coding system known for efficient classification of steel as it uses the standards from the American Iron and Steel Institute (A.I.S.I.) and the Society of Automotive Engineers (S.A.E.).

For 1020, The first number ‘1’ indicates that the steel is Carbon steel,the second number ‘0′ means that the steel has no important alloy elements,the last two numner’20’ show that this steel has 0.20% carbon.

AISI 1020 Steel Chemical Compostion as below:

Carbon(C):0.18-0.23%

Manganese (Mn):0.3-0.6%

Phosphorus (P): Max 0.04%

Sulfur (S):Max 0.05%

WHAT IS CARBON STEEL?

Carbon steel can be divided t to three main categories: Low Carbon Steel (known as Mild Steel); Medium Carbon Steel; and High Carbon Steel.

Low Carbon Steel:Carbon content below 0.25%,this is one of the largest groups of Carbon Steel. It covers a great diversity of shapes; from Flat Sheet to Structural Beam. Depending on the desired properties needed, other elements are added or increased.This type of steel is suitable for kinds of process,such as forging,welding,and cutting,and widely used for shafts,bolts,gears.Typical Grade:AISI 1010,AISI 1018 Steel.

Various Shapes For Carbon Steel

Medium Carbon Steel:Carbon content:0.25-0.6%,and a Manganese content ranging from 0.70% to 1.2%. This tpye of steel has good hot woking and cutting performance, but poor in welding. They have good strength and hardness higher than low carbon steel, while plasticity and toughness are lower than low carbon steel.Typical grade:AISI 1040,AISI 1045 steel.

Hot-rolled and cold-drawn products from this steel can be used directly without heat treatment, and also they can be used after heat treatment. The quenched and tempered medium carbon steel has good comprehensive mechanical properties. The highest hardness that can be achieved about HB 538, and the tensile strength is 600~1100MPa.

Therefore, among the various uses of medium strength level, medium carbon steel is the most widely used. In addition to being used as a building material, it is also widely used in the manufacture of various mechanical parts.

High Carbon Steel: Carbon content:above 0.6%, is also called carbon tool steel, with a carbon content from greater than 0.60% to 1.70%, which can be hardened and tempered.Typical Grade:AISI 1060 Steel.

Hammers, crowbars, etc. are made of steel with a carbon content of 0.75%; cutting tools such as drills, taps, and reamers are made of steel with a carbon content of 0.90% to 1.00%.

The higher the carbon content, the greater the hardness and strength, but the lower the plasticity.High carbon steel is very difficult to cut, bend and weld. Once heat treated it becomes extremely hard and brittle.

HOW IS AISI 1020 STEEL MELTING AND REFINING?

AISI 1020 Steel is made by Electric arc furnaces(EAF) which is most commoly used in the steel mills in the world.This method converts electrical energy into heat energy, also known as electric arc furnace steelmaking.

Graphite electrodes, a thermally conductive material, are used to generate electric arcs in the electric furnace by discharging between the electrodes and the charge, resulting in the conversion of electrical energy into heat in the arc. Electric arc heating melts metal and slag to smelt steels of various compositions. Electric furnace steelmaking mainly uses scrap steel as raw materials, which consumes less pig iron and no longer requires a large amount of coke.

The molten steel is formulated to precise chemical compositions during the secondary refining processes.The main function of refining outside the furnace is to improve the quality of molten steel, expand the range of varieties, optimize the metallurgical production process, and improve production efficiency.

The main modern refining equipment includes LF and RH refining furnaces. The main function of RH refining furnaces is to remove harmful gases and impurities in molten steel and carry out deep decarburization. LF furnaces have functions such as heating, desulfurization, and deoxidation alloying.

The refined steel which is poured into various ingots or billets of different shapes and different cross-sectional dimensions is usually by die casting or continuous casting method. The solidified shapes are processed into finished goods by various processes, including hot rolling, hot forging,cold rolling, annealing.

QUICK QUESTIONS FOR AISI 1020 STEEL

Is AISI 1020 Steel Low Carboon Steel?

With carbon content 0.18-0.23%,there is no doubt that AISI 1020 steel is segregated to low carbon steel category.It has all the properties which low carbon steel has,excellent machinability,good ductility and good weldability performance.

Is AISI 1020 Steel Easily Machined and Formed?

AISI 1020 steel material is capable of being worked on via a machine. Malleability and ductility are never a question for AISI 1020.

Can You Easily Weld 1020 Steel?

AISI ends with the number 20! It is why it has good weldability because of its low carbon content (20%). Welding and forming it to desired forms and shapes is easy.

Is AISI 1020 Steel Corrosion Resistant?

AISI 1020 is known as its good toughness, plasticity and weldability used as concrete reinforcement and small machine parts,but it is prone to severe corrosion,especially in hydrogen sulfide(H2S) conditon.

Is AISI 1020 Steel Hard Enough?

AISI 1020 steel have a surface hardness below 156HBW without heat treatment,after forged or rolled.It is difficult to quench this material due to the low carbon content,but with carburizing,it can achieve hardness 30-35HRC.

AISI 1018 Steel vs AISI 1020 Steel

The 1018 type of steel comes from the same family of the AISI 1020 steel. The only slight difference is their percentage of carbon content. 1018 steel ends with 18, meaning it has 18% carbon, which is 2% lower than AISI 1020, having 20%.Its popularity equates with the AISI 1020 and is also one of the most purchased types of carbon steel. Hence, both are okay with heat treatments and cold-drawn situations.

AISI 1018 Forged Round Steel Bar

WHAT IS A105 STEEL ?

A105 is an American standard which belongs to ASTM A105/A105M-2018:Standard Specification for Carbon Steel Forging for Piping Applications.

The letter ‘A’ stands for common carbon structural steel.Since only one type of carbon steel forging is specified in this standard, A105 is also regarded as a carbon steel grade of forging. A105 is also a material code, which belongs to special steel and is a kind of cold forged steel.

A105 Steel Applications

WHAT IS THE DIFFERENCE BETWEEN AISI 1020 STEEL AND A105 STEEL?

The strength of AISI 1020 steel is slightly higher than that of 1015 steel, hardly quenched, and no temper brittleness. Cold deformation has high plasticity and is generally used for bending, rolling, flange and hammer arching.

The welding performance of arc welding and contact welding is good, the thickness is small during gas welding, and cracks are prone to occur on parts with strict requirements or complex shapes.

The machinability:Cold drawn or normalized condition is better than the annealed condition, and AISI 1020 steel is generally used to manufacture products with low stress and high toughness requirements.

A105 is a low-carbon steel forging with mechanical properties between AISI 1020 forged steel and Q345B forged steel

In the piping system, A105 steel can generally replace AISI 1020, but AISI 1020 steel cannot completely replace A105 because the difference in strength is still large. Different strength differences determine different product structures.The stress corrosion cracking (SCC) resistance of A105 is slightly worse than that of AISI 1020.We can easily have an intuitive comparison from in the below tables.

Chemical Compositon Comparison

| AISI 1020 | A105 |

| Carbon(C):0.18-0.23% | Carbon(C):0.35% Max |

| Manganese(Mn):0.3-0.6% | Manganese(Mn):0.6-1.05% |

| Phosphorus(P):0.04% Max | Phosphorus(P):0.035% Max |

| Sulfur(S):0.05% Max | Sulfur(S):0.04% Max |

| - | Silicon(Si):0.1-0.35% |

| - | Copper(Cu):0.4% Max |

| - | Nickel(Ni):0.4% Max |

| - | Chromium(Cr):0.3% Max |

| - | Molybdenum(Mo):0.12% Max |

| - | Vanadium(V):0.08% Max |

Mechanical Property Comparison

| AISI 1020 | A105 |

| Tensile Strength:≥410Mpa | Tensile Strength:≥485Mpa |

| Yield Strength:≥245Mpa | Yield Strength:≥250Mpa |

| Elongation:≥25% | Elongation:≥22% |

| Reduction of Area:≥55% | Reduction of Area:≥30% |

| Hardness:≤156HBW | Hardness:≤187HBW |

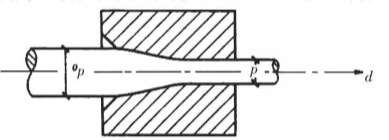

IS AISI 1020 STEEL SUITABLE FOR COLD DRAWING PROCESS?

AISI 1020 Steel has good cold drawn performance.When strengthening 1020 steel,it has more crystal lattice defects during plastic deformation,and the severe distortion of the defective crystal lattice will hinder the further slippage of the crystal lattice, so the yield point of the steel is increased, and the plasticity and toughness are reduced.Due to the internal stress generated in the plastic deformation, the elastic modulus of the steel is reduced.

AISI 1020 cold-drawn steel bars are stored at room temperature for 15-20 days or heated to 100-200℃ and kept for a certain period of time. This process is called aging treatment. After cold drawing, the yield point of 1020 steel is further improved, the ultimate tensile strength is also increased, and the plasticity continues to decrease. Due to the reduction of internal stress during the aging process, the elastic modulus can be basically restored.

AISI 1020 STEEL APPLICATION-WHAT IS IT USED FOR?

Industrial sectors largely utilize this type of steel. A variety of industrial applications can be applied with this type of steel due to its ability to be used in cold-drawn conditions and beautiful polished finish properties. For simple structural applications, you can never go wrong with AISI 1020.

AISI 1020 steel is suitable for the manufacture of small and medium carburizing and carbonitriding parts that are not important for the construction of automobiles, tractors and general machinery manufacturing, such as handbrake shoes, lever shafts, gearbox speed forks, transmission passive gears and tractor camshafts, suspension equalizer shafts, equalizer inner and outer bushings, etc.

Common Applications of AISI 1020 carbon steel

AISI 1020 is used to manufacture various mechanical parts that are not stressed but require high toughness under hot-rolled or normalized conditions.And it is also used for forged or pressed tie rods, shackles, levers, sleeves, clamps in heavy and medium-sized machinery manufacturing.

In the steam turbine and boiler manufacturing industry, it is mostly used for pipes, flanges, headers and various fasteners working in non-corrosive media with a pressure under 6N/square and a temperature under 450℃.In the railways and rolling stock manufacturing industry,it is used in the manufacture of castings such as crossheads and pistons .

WHERE TO BUY AISI 1020 STEEL IN CHINA?

The AISI 1020 steel type can be easily found in the market but acquiring them from the best and trusted 1020 steel manufacturer could be the most formidable challenge to buyers and product sourcing agents.

Why China Steel Manufacturers? Chinese steel offers the best in terms of competitive pricing, volume, and quality. For AISI 1020 steel needs in different forms, sizes, types, and tolerance, partner with us, and we can guarantee you the best steel found here.

What We Supply For AISI 1020 Steel

| Form of Supply | Size(mm) |

| Round | Φ80-Φ1000 |

| Square | 100 x 100-600x600 |

Flat/Blcoks | Thickness :120-800 |

| Width:120-1500 |

Heat treatment:Normalized(+N),Annealed(+A)

Why Choose Us?- Your Reliable AISI 1020 Steel Supplier

As certified ISO- 9001 Quality Management Systems, we strictly adhere to the highest standards of quality control of producing top quality steels like AISI Carbon 1020 Steel starting from the acquiring and selection of raw materials (before production), during production processes, after production, and even up to handling customers.

All minute and significant operations are governed with standards and strict quality control monitoring to ensure the product is 100% conformance to specifications.Being the best and the premium 1020 steel supplier, we can give you pre-made and custom 1020 steels!