18NiCrMo5 steel is an alloy structural steel containing Ni-Cr-Mo elements according to the UNI 8550 standard, with high strength and plasticity, moderately high hardenability and good machinability.

In fact, among the special case hardening steels, 18NiCrMo5 steel is the most famous and used steel in Italy, widely used in the production of wear-prone parts such as gears, pinions, bushings, camshafts.

18NiCrMo5 steel is generally used in the quenched and tempered condition or carburized and quenched condition.

18NiCrMo5 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 18NiCrMo5 | 0.15-0.21 | ≤0.4 | 0.6-0.9 | ≤0.035 | ≤0.035 | 0.7-1.0 | 1.2-1.5 | 0.15-0.25 |

18NiCrMo5 STEEL RELATED STANDARD & EQUIVALENT GRADE

Europe/EN:17NiCrMo6-4 | DIN 1.6566

UK/BS:815M17

France:18NCD6

Sweden:SS2523

18NiCrMo5 STEEL FORGING

- Initial Forging Temperature:1100-1150℃

- Final Forging Temperature:above 900℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:As a low carbon Cr-Ni-Mo series alloy steel, 18NiCrMo5 is a white point sensitive steel. After forging, dehydrogenation annealing heat treatment should be done immediately.

18NiCrMo5 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 18NiCrMo5

- Ac1:730ºC

- Ac3:815ºC

- Ms:360ºC

Hardness of Different Types of Annealing for 18NiCrMo5

- Soft Annealing:≤240HBW

- Isothermal Annealing:149-207HBW

- Spheroidizing Annealing:≤207HBW

Temperature Selection for Different Types of Heat treatment for 18NiCrMo5

- Normalizing: 850 – 900°C,Cooling in air

- Isothermal annealing:850 – 900°C,Cooling to 650°C with 2 hours time holding.Cooling in furnace

- Subcritical Annealing:650 – 700°C,Cooling in furnace

- Carburizing:870-900°C

- Core-hardening:840-870°C,oil-polymer salt bath

- Case-hardening:800-830°C,oil-polymer salt bath

- Tempering:150-200°C

18NiCrMo5 Steel Mechanical Property with Quenched and Tempered Condition

| Thickness/Diameter,mm | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Impact,KCU, J |

| ≤11 | 1225-1520 | ≥980 | ≥8 | ≥30 |

| 11-25 | 1030-1325 | ≥785 | ≥9 | ≥32.5 |

| 25-40 | 930-1230 | ≥735 | ≥9 | ≥32.5 |

| 40-100 | 785-1080 | ≥590 | ≥10 | ≥35 |

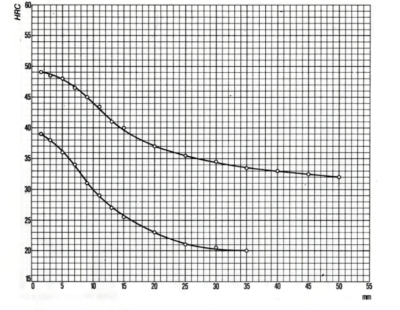

Jominy Quenching Test Curve For 18NiCrMo5 Steel

Quenching at 850°C

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

18NiCrMo5 | HRC Min | 39 | 38 | 36 | 34 | 31 | 29 | 27 | 25.5 | 23 | 21 | 20.5 | 20 | – | – | – |

| HRC Max | 49 | 48.5 | 48 | 46.5 | 45 | 43.5 | 41 | 40 | 37 | 35.5 | 34.5 | 33.5 | 33 | 32.5 | 32 | |

18NiCrMo5 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |