AISI 4340 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.AISI 4340 is defined as a heat treatable and low alloy steel which has 0.8% Cr, 0.2% Mo and 1.8% Ni as strengthening alloy elements.Compared with AISI 4140,it has higher strength and toughness,also it has very good fatigue resistance, wear resistance and atmospheric corrosion resistance.AISI 4340 is generally supplied in hardened and tempered condition with the tensile range of 930 – 1080 Mpa ,hardness 280-320HB.Pre hardened and tempered 4340 can be further surface hardened by flame or induction hardening and by nitriding.

1.Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

2.Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| ASTM A29 | 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | ≤ 0.035 | ≤ 0.04 | 0.7-0.9 | 1.65-2.0 | 0.2-0.3 |

EN10250 | 36CrNiMo4 | 0.32-0.4 | ≤ 0.4 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.9-1.2 | 0.90-1.2 | 0.15-0.3 |

| 1.6511 | |||||||||

BS 970 | EN24 | 0.36-0.44 | 0.1-0.4 | 0.45-0.7 | ≤ 0.035 | ≤ 0.04 | 1.0-1.4 | 1.3-1.7 | 0.2-0.35 |

| 817M40 | |||||||||

| JIS G4103 | SNCM439 | 0.36-0.43 | 0.15-0.35 | 0.6-0.9 | ≤ 0.03 | ≤ 0.03 | 0.6-1.0 | 1.6-2.0 | 0.15-0.3 |

| GB 3077 | 40CrNiMoA | 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | ≤ 0.025 | ≤ 0.025 | 0.6-0.9 | 1.25-1.65 | 0.15-0.25 |

3.Physical Property

| Density g/cm3 | 7.85 | ||||

| Melting point °C | 1427 | ||||

| Poisson's ratio | 0.27-0.30 | ||||

| Machinability (AISI 1212 as 100% machinability) | 50% | ||||

| Thermal expansion co-efficient µm/m°C | 12.5 | ||||

| Thermal conductivity W/(m.K) | 44.5 | ||||

| Modulus of elasticity 10^3 N/mm^2 | 210 | ||||

| Electric resistivity Ohm.mm2 /m | 0.19 | ||||

| Specific heat capacity J/(kg.K) | 460 | ||||

Modulus of elasticity 10^3 N/mm2 | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 205 | 195 | 185 | 175 | 165 | |

Thermal expansion 10^6 m/(m.K) | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 11.1 | 12.1 | 12.9 | 13.5 | 13.9 | |

4. Mechanical Property

| Mechanical Condition | T | U | V | W | X | Y | Z |

| Ruling Section (mm) | 150 | 100 | 63 | 30 | 30 | 30 | 30 |

| Tensile Strength Mpa | 850-1000 | 930-1080 | 1000-1150 | 1080-1230 | 1150-1300 | 1230-1380 | >1550 |

| Yield Strength,Mpa | ≥665 | ≥740 | ≥835 | ≥925 | ≥1005 | ≥1080 | ≥1125 |

| Elongation % | ≥13 | ≥12 | ≥12 | ≥11 | ≥10 | ≥10 | ≥5 |

| Izod Impact J | ≥54 | ≥47 | ≥47 | ≥41 | ≥34 | ≥24 | ≥10 |

| Charpy Impact J | ≥50 | ≥42 | ≥42 | ≥35 | ≥28 | ≥20 | ≥9 |

| Brinell Hardness HB | 248-302 | 269-331 | 293-352 | 311-375 | 341-401 | 363-429 | >444 |

5.High Temperature Strength

| For quenched and tempered heavy forgings | |||||||

Diameter mm | Yield strength MPa | ||||||

| 20 ℃ | 100 ℃ | 200 ℃ | 250 ℃ | 300 ℃ | 350℃ | 400℃ | |

| ≤250 | 590 | 549 | 510 | 481 | 441 | 412 | 371 |

| 250-500 | 540 | 505 | 471 | 451 | 412 | 383 | 353 |

| 500-750 | 490 | 466 | 441 | 422 | 392 | 363 | 343 |

6.Forging

Forging temperature should be carried out between 1150℃-1200℃,The lower the forging-ending temperature ,the finer the grain size .hold suitable time for the steel to be thoroughly heated before forge, but don’t forge below minimum forging temperature 850°C. AISI 4340 has good forging characteristics,but crack is easily occured when improper cooling way after forged,so it should be cooled as slowly as possible in still air or in sand after forged.

7.Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.Normalizing temperature for AISI 4340 steel should be carried out between 850℃-880℃. hold suitable time for the steel to be thoroughly heated to complete the ferrite to austenite transformation.Cool in still air.

8.Annealing

Full annealing is recommended for AISI 4340 before machining, AISI 4340 should be carried our at a nominal temperature of 830℃-850℃,hold suitable time for the steel to be thoroughly heated, then furnace cooling to 610℃ at a rate of 11℃ per hour, finally air cooling.

9.Hardening

This heat treatment will obtain martensite structure after quenched.It will increase the surface hardness and strength.AISI 4340 should be carried out between 830℃-865℃, hold suitable time for the steel to be thoroughly heated, soak for 10-15 minutes per 25 mm section, oil quench is recommended.Tempering should be followed immediately after quenched.

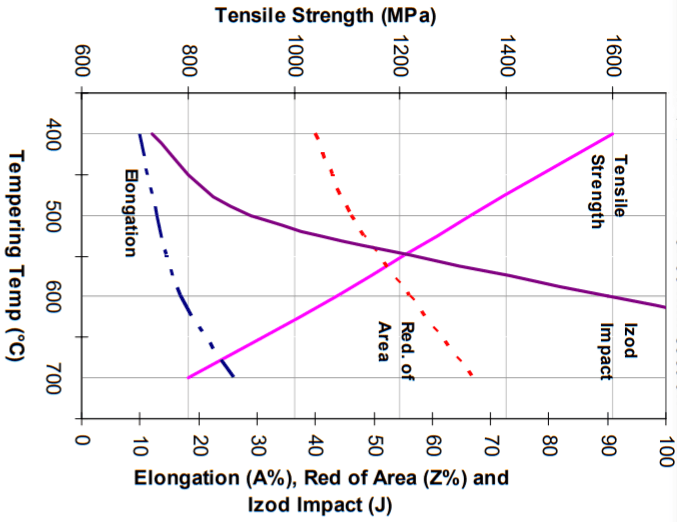

10.Tempering

AISI 4340 alloy steel should be in the heat treated or normalized and heat treated condition before tempering.Tempering is usually carried out to relieve stresses from the hardening process, but primarily to obtain the required hardness and mechanical properties. The actual tempering temperature will be chosen to meet the required properties.it is usually carried out at 450℃- 660℃,hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm of section, and cool in still air.Tempering between 250℃-450℃ is not avoided as tempering within this range will seriously reduce the impact value,result in temper brittleness.

11.Application

AISI 4340 is often used in preference to AISI 4140 at the higher strength levels because of its better hardenability and improved CVN impact toughness.

Typical applications include:Heavy-duty axles, shafts, heavy-duty gears,spindles, pins, studs, collets, bolts, couplings,sprockets, pinions, torsion bars, connecting rods,crow bars, conveyor parts,forged hydraulic,forged steel crankshafts etc.

AISI 4340 ENGINEERING STEEL-ULTIMATE GUIDELINES FOR PURCHASING

When you are in the market to find AISI 4340 Steel,it seems simple.but actually, you have to face numerous manufacturers with different quality level.

How to choose?But no idea about where to purchase?

The below guide will explain to you every prospect about AISI 4340 Steel,we’ll teach you how you can find the best and the highest quality of 4340 steel from the best supplier!

So, let’s get started.

WHAT IS AISI 4340 STEEL?

AISI 4340 Steel is a particular type of steel alloy assigned prefix code by the AISI system.This letter prefix is mainly used to denote the steelmaking process of the AISI 4340 Steel.

The grade number in the steel alloys makes sure to differentiate their industrial applications.

4: The first number ‘4’ indicates that the steel is ‘Molybdenum’ steel and Molybdenum is most important alloy element for this steel as compared to other steel series.

3:The second number’3′ means that three (3) elements are present, and they include nickel, chromium, and molybdenum.

40: The last two numbers ‘40’ indicates the amount of carbon present in the steel. For this grade it has 0.40% carbon same as AISI 4140 steel.

Moreover, this particular number is assigned to almost all the steel alloys by AISI to designate the different steel compositions in its alloys.

WHICH FORMS OF AISI 4340 STEEL CAN BE SUPPLIED IN THE MARKET?

AISI 4340 Steel is supplied in round, square, flat, block, and shaft forms from China to other countries.Besides all the forms mentioned above, some other supply forms of AISI 4340 steel include the plain sheets and hexagonal bars.

The properties and the composition of the AISI 4340 steel remain the same regardless of their shape.In addition to this, the sturdy nature of AISI 4340 Steel has made it importable in the form of hardened and tempered conditions.

You have to keep in mind to provide options to the manufacturer while ordering them to supply AISI 4340 steel.

AISI 4340 Forged Round Steel with Quenched and Tempered Conditon-Dia 780mm

WHAT ARE EQUIVALENT INTERNATIONAL GRADES FOR AISI 4340 STEEL?

With the development of global trade, global procurement, manufacturing and engineering, the demand for steel grades from different countries has become more and more urgent.

But each country has different material standards and grades.For example, the European Union, the United States, Japan, and China have their own steel standards and grade systems.They design and substitute materials according to their actual situation,that’s why there is a demand for alternative steel grades.

AISI 4340 Steel, popular American grade steel, which is made of high-quality carbon structural steel by appropriately adding one or several alloying elements (Cr-Ni-Mo with a total content of not more than 5%).We can see the differences between different national standards from the table below.

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| ASTM A29 | 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | ≤ 0.035 | ≤ 0.04 | 0.7-0.9 | 1.65-2.0 | 0.2-0.3 |

EN10250 | 36CrNiMo4 | 0.32-0.4 | ≤ 0.4 | 0.5-0.8 | ≤ 0.035 | ≤ 0.035 | 0.9-1.2 | 0.90-1.2 | 0.15-0.3 |

| 1.6511 | |||||||||

BS 970 | EN24 | 0.36-0.44 | 0.1-0.4 | 0.45-0.7 | ≤ 0.035 | ≤ 0.04 | 1.0-1.4 | 1.3-1.7 | 0.2-0.35 |

| 817M40 | |||||||||

| JIS G4103 | SNCM439 | 0.36-0.43 | 0.15-0.35 | 0.6-0.9 | ≤ 0.03 | ≤ 0.03 | 0.6-1.0 | 1.6-2.0 | 0.15-0.3 |

| GB 3077 | 40CrNiMoA | 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | ≤ 0.025 | ≤ 0.025 | 0.6-0.9 | 1.25-1.65 | 0.15-0.25 |

HOW TO HARDEN AISI 4340 STEEL?

AISI 4340 alloy structural steel belongs to gear steel which has high strength, toughness and outstanding hardenability and anti-thermal stability.

AISI 4340 Steel is used for heavy machinery high-load shafts, turbine shafts with a diameter greater than 250 mm, helicopter rotor shafts, turbojet engine turbine shafts, blades, high-load transmission parts, crankshafts,gears,etc.

But before we use them for above applications,we need to harden the materials according to requirements.In the actual production process,we often use water quench and oil quench to harden AISI 4340 Steel.

| Water Quench | Oil Quench | |

| Quench Medium | Water | Oil |

| Quench Temperature | 850~870℃ | 850~870℃ |

| Quench Time | Normal | Longer |

| Cooling ability | Better | Normal |

| Crack Resistance | Poor | Normal |

| Deformation | Bigger | Normal |

| Hardness | Higher | Normal |

| Hardenability | Better | Normal |

| Tempering Following | Immediately | Immediately |

WHAT IS THE HARDNESS FOR AISI 4340 STEEL?

When we use AISI 4340 steel for applications,we choose its high strength,high hardness and excellent toughness.Normally,AISI 4340 steel has a hardness below 229 HBW under annnealed conditon,248-302HBW under quenched and tempered condition.With suitable hardening process,it can even achieve surface hardness up to 60HRC.

But can it be considered that the higher the hardness, the better the performance?Of course not.

The higher the hardness, the greater the strength, but the plasticity and toughness decrease. Especially in the case of quenching and tempering conditon, in order to ensure the strength, it is necessary to find a balance point between the strength and the toughness.

AISI 4340 Steel Chart:Tempering temperature VS Tensile VS Enlogation VS Reduction of Area & Impact

HOW TO FORGE AISI 4340 STEEL?

As a very popoluar grade,AISI 4340 Steel has good forging performance,but with Cr-Ni-Mo alloy elements,it must be paid more attention when forging.Here are some important key points need to be concerned.

- Initial Forging Temperature

Initial forging temperature for AISI 4340 Steel must be controled between 1180-1230℃ when heating in the furnace.Once higher than this temperature,it may cause overheated structure and decarburization.But the initial forging temperature should not be too low, otherwise it will shorten the forging operation time, narrow the forging temperature range, and increase the difficulty of forging.

- Final Forging Temperature

Final forging temperature for AISI 4340 Steel,in our experience should be operated above 850℃.Generally speaking, the final forging temperature should be as low as possible, which can extend the forging time and reduce the number of heating. However, if the temperature is too low, the plasticity of the material decreases, the deformation resistance increases, and the forgeability also deteriorates. The material will also be work hardened and even cracked. If the final forging temperature is too high (that is, stop forging at high temperatures), the forgings will have coarser grains and lower mechanical properties.

AISI 4340 Steel Shaft Forging By 1600T Forging Press

- Forging Ratio

As the forging ratio increases during the forging process, the internal pores are compressed, the casting grain structure will be broken, and the longitudinal and transverse mechanical properties of the forging material are significantly improved. If the forging section ratio is too small, the forging will not meet the performance requirements, and also cause th internal structure loose,but if it is too large, it will increase the forging workload and cause anisotropy.According to our experience,for AISI 4340 Steel bars,we usually control the forging ratio with Upsetting and Drawing Process,and guarantee it above 4:1

Upsetting & Drawing Process Diagram

- Cooling Method After Forged

AISI 4340 Steel is an alloy structural steel with high hardenability which contains Cr-Ni-Mo alloy elements.Uneven cooling or local rapid cooling will cause great internal stress,and may easily causes surface cracks.It is recommended that it should be buried sand cooling or furnace cooling after forged.

In our experience,the best way to cooling 4340 steel is annealing.The main purpose is to prevent white spots and hydrogen embrittlement, eliminate internal stress, reduce hardness, improve the cutting performance of forgings, improve the internal structure of the parts, refine the grains, and prepare for the final heat treatment.

HOW TO AVOID TEMPERING BRITTLENESS FOR AISI 4340 STEEL?

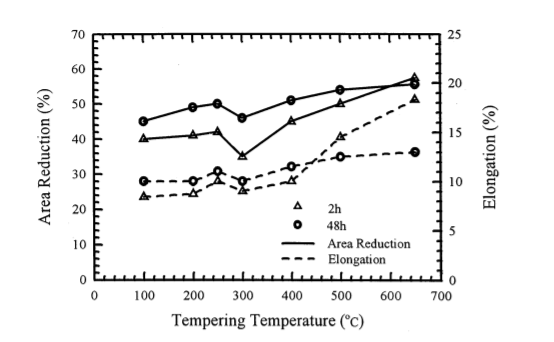

With the increase of the heating temperature in the tempering process,the hardness and strength of the steel decrease, while the ductility and toughness increase, but the impact value is significantly reduced to the lowest value when tempered within a certain temperature range. This phenomenon is called tempering brittleness.

Similarly, AISI 4340 steel also has this tempering brittleness feature .Research shows that there is a big loss in toughness(especially for Charpy V-notch impact)after tempering at around 300°C due to retained interlath austenite and the formation of interlath carbide films.

Fracture analysis shows that for all of the tempering temperatures, the fracture features are predominated by the ductile mode with a dimple structure, except for the case of 300°C,where the material failed in a brittle manner due to the occurrence of tempered martensite embrittlement.

From the above, we can know that,We should avoid tempering AISI4340 steel at around 300 degrees with long time.

Relation Chart:AISI 4340 Steel Tempering Temperature VS Area Reduction & Elongation

QUICK QUESTIONS FOR AISI 4340 STEEL

Is AISI 4340 Stainless Steel?

Stainless steel has at least 10.5% Chromium, and the maximum carbon content is not more than 1.2%.The main characteristics for these kind materials are good rust resistance and corrosion resistance.

While AISI 4340 is defined as a heat-treatable low-alloy steel containing 0.8% Cr, 0.2% Mo and 1.8% Ni as strengthening alloying elements.Compared with Stainless steel,it has higher strength and toughness, but its wear resistance and atmospheric corrosion resistance are not as good as stainless steel.

Is AISI 4340 Steel Corrosion Resistant?

AISI 4340 steel is a medium-carbon nickel-chromium-molybdenum steel which has excellent tensile strength, toughness and fatigue resistance.

AISI 4340 Steel is highly resistant to atmospheric corrosion because of its combined alloy elements of chromium, molybdenum,nickel and manganese which can not only improve the strength and hardenability of steel, but also improve corrosion resistance.

The corrosion-resistant nature of the AISI 4340 Steel is responsible for its use in the forged hydraulic systems,and it is also used in many other machine appliances, including those involved in the aerospace industry.

Is AISI 4340 Steel Magnetic?

AISI 4340 Steel is manufactured with many basic properties, including high magnetic properties.Other than magnetic properties, the AISI 4340 Steel is also equipped with durable mechanical properties.

This steel allows very substantial magnetic properties because a few percent of alloying elements are present.The magnetization of the AISI 4340 steel is estimated at up to 21500 Gauss.

Can You Machine AISI 4340 Steel?

Yes, you can machine AISI 4340 Steel with the help of almost all types of conventional techniques.No excess carbon contents are present, that’s why AISI 4340 steel can be machined easily.

This grade is easy to process, depending on the size and complexity of the section and the amount of processing to be carried out.The machining of AISI 4340 steel is carried out under an assumed shape.

However, the recommended machining process for AISI 4340 Steel is carried out under annealed,normalized and tempered environments.

How is The Weldability of AISI 4340 Steel?

AISI 4340 Steel is recommended to weld in the annealed condition, but welding in the quenched and tempered state should be avoided as much as possible, because this will affect the mechanical properties. It is not recommended to weld under nitriding, flame or induction hardening conditions.

In addition to this, the weldability of the AISI 4340 steel is carried out by preheating the material at 200 to 300 degrees.This high temperature for the welding is maintained to ensuring the sustainability of the substrate.The welded parts should be cooled slowly in the ashes or sand, and the stress should be relieved as much as possible.

WHAT IS 4340M STEEL?

4340M steel which is modified from AISI 4340 Steel,also known as 300M, is the steel grade in the American AMS standard.It is a low-alloy ultra-high-strength steel,the addition of vanadium and higher silicon content is added to produce higher strength levels.

Chemical Composition Comparison

| 4340M | 4340 | |

| Standard | AWS 6417 | ASTM A29 |

| C | 0.38-0.43 | 0.38-0.43 |

| Si | 1.45-1.80 | 0.15-0.35 |

| Mn | 0.6-0.9 | 0.6-0.8 |

| P | ≤ 0.01 | ≤ 0.035 |

| S | ≤ 0.01 | ≤ 0.04 |

| Cr | 0.7-0.95 | 0.7-0.9 |

| Ni | 1.65-2.0 | 1.65-2.0 |

| Mo | 0.3-0.5 | 0.2-0.3 |

| V | 0.05-0.1 | - |

Mechanical Performance Characteristics

- High Strength

After oil quenching and tempering with standard heat treatment, the tensile strength of 4340M steel can reach above 1860MPa, which is the highest strength low-alloy ultra-high-strength steel among the currently used materials.

High strength can reduce the weight of parts, and improving strength has always been one of the main goals pursued in the design of landing gear parts.The important load-bearing components of American aircraft wings have also adopted 4340M steel and used it to the highest level of strength.

- High Lateral Plasticity

In the material standard, the transverse section shrinkage rate as the main mechanical performance index is the characteristic of 4340M steel.This is based on the characteristics of the use of landing gear parts.

- High Fracture Toughness

High fracture toughness indicates strong resistance to crack growth. When selecting materials, attention should be paid to both sharp notch toughness and blunt notch toughness. They represent different physical meanings, so they cannot replace each other.

- Excellent Fatigue Performance

The fatigue resistance of 4340M steel is obviously excellent. This is extremely beneficial to the long-life use of landing gear and other aircraft components, and is also the main reason why 4340M steel is widely used in aircraft.

- Good Corrosion Resistance

1.5% silicon in the composition improves the stress corrosion resistance of 4340M steel. Compared with similar steels, its stress corrosion resistance is better.

HOW TO FIND THE BEST MANUFACTURER OF AISI 4340 STEEL IN CHINA?

When you need AISI 4340 steel, but you can’t find a suitable supplier from so many manufacturers.Try us

We can be your best pick for AISI 4340 Steel since it makes sure that every aspect meets customer’s demands.

What We Supply For AISI 4340 Steel

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

What Heat Treatment We Supply For AISI 4340 Steel

- Normalized(+N)

- Annealed(+A)

- Quenched & Tempered(+QT)

What Size We stock For AISI 4340 Steel

- Hot Rolled Round Bar:Φ18-Φ200mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ230mm,10 days Delivery

- Customized service:Special Size & Length,30 days Delivery

We Supply Free Sample of AISI 4340 Steel

Before you buy AISI 4340 Steel from us, you can try to get samples from us for Tesing and Evaluating.It’s just one way of us proving to you that our goal and our mission is to provide quality products!

In fact, if you need to buy AISI 4340 and 4140 steel, you can trust us! Our employees always maintain an open attitude and are willing to provide you with help and assistance!