As one of the representative steel types of plastic mold steel, 1.2312 steel is developed on the basis of 1.2311 steel. 1.2312 steel uses Cr-Mn-Mo as a strengthening alloy element, and adds a higher content of sulfur element (0.05-0.1% ),which offers better machineability,30% increase in milling speed and 300% increase in drilling speed can be expected.

1. 2312 steel has excellent cutting performance, good toughness and wear resistance, stable size and uniform hardness after processing.DIN 1.2312 is generally supplied in pre-hardened condition,with a hardness of 280-320HB.

1.2312 Steel Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

1.2312 Steel Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo |

| 1.2312 | 0.35-0.45 | 1.4-1.6 | ≤ 0.03 | 0.05-0.1 | 0.3-0.5 | 1.8-2.0 | 0.15-0.25 |

1.2312 Steel Relevant Standards

USA:P20+S

Germany:40CrMnMoS8-6

France: 40CMD8S

1.2312 Steel Physical Property

| Density, g/cm3 | 7.85 | ||

| Specific heat J/kg·K | 470 | ||

| Thermal expansion coefficient 10 ^-6m/(m·K) | 20-100°C | 20-200°C | 20-300°C |

| Annealed | 12.5 | 13.4 | 13.9 |

| Tempered | 12.3 | 13 | 13.7 |

| Thermal conductivity W/(m · K) | 100°C | 200°C | 300°C |

| Annealed | 40.2 | 40.3 | 39 |

| Tempered | 39.8 | 40.4 | 39 |

Forging DIN1.2312 Steel

- Initial Forging Temperature:1050-1100℃

- Final Forging Temperature:850℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:Cooling as slowly as possible in sand after forged.In addition, 1.2312 steel do annealing after forged is also a good recommendation.

1.2312 Steel Heat Treatment

- Normalizing: 880 – 900°C,Cooling in air

- Annealing:760 – 790°C,Cooling in furnace,Hardness:Max 241HB

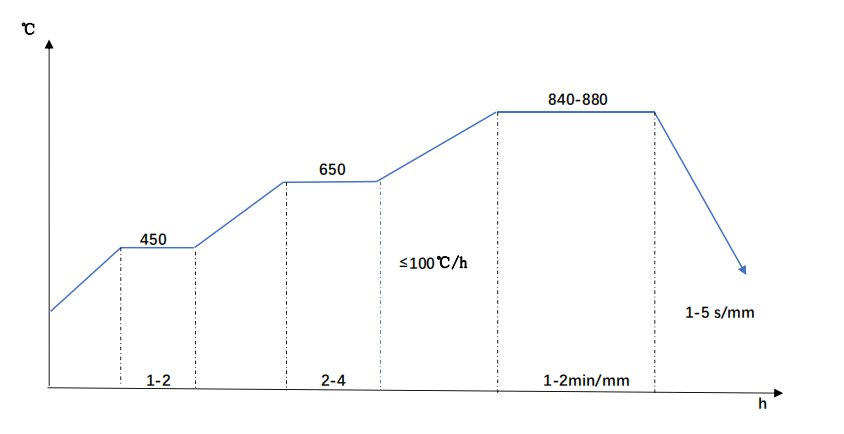

- Quenching:840 – 880°C,Oil quenching is preferred,Quenching Hardness: Max 52HRC.

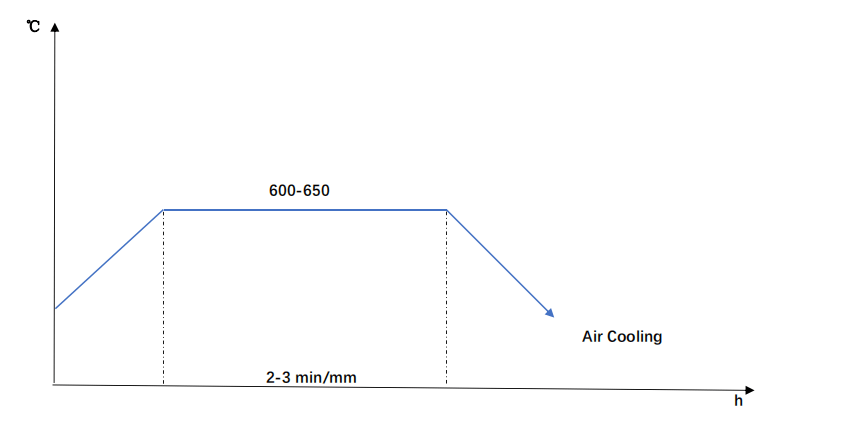

- Tempering:600 – 650°C,Cooling in air,Hardness:28-36HRC.

DIN 1.2312 Steel Quenching Diagram

DIN 1.2312 Steel Tempering Diagram

Correspondence between hardness and tensile strength at different tempering temperatures

| Tempering temperature,°C | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| Hardness,HRC | 51 | 50 | 48 | 46 | 42 | 36 | 28 |

| Tensile,Mpa | 1730 | 1670 | 1570 | 1480 | 1330 | 1140 | 920 |

DIN 1.2312 Steel Mechanical Property at Quenched and Tempered condition

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact | Hardness |

| 960Mpa | 850Mpa | 10% | 45% | 20J | 300HB |

1.2312 Steel Application

DIN1.2312 tool steel is used for the production of moulds where improved machinability is required,and for plastics processing and moulds for pressure die casting.

Typical applications include die holders, zinc die casting dies, backers, bolsters and injection moulds,machine construction, jigs, base plates, assembling parts, moulding frames, plastic moulds, plastic processing, die casting moulds, hydroforming tools, recipient sleeves, folding bars, tool holders,etc.