AISI 9840 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.

AISI 9840 is defined as Cr-Ni-Mo series alloy steel as per USA standard ASTM A519.AISI 9840 steel is very similar to AISI 4340 steel, only the Ni element is lower, and the difference in other elements is almost negligible.

AISI 9840 steel has excellent performance after heat treatment, such as hardenability, strength and toughness, and wear resistance.It is usually used for seamless mechanical tubing,and also suitable for engineering applications,such as shafts,connected rods,gear shafts and crankshafts.

AISI 9840 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

AISI 9840 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| 9840 | 0.38-0.42 | 0.15-0.35 | 0.7-0.9 | ≤0.04 | ≤0.04 | 0.7-0.9 | 0.20-0.30 | 0.85-1.15 |

AISI 9840 STEEL RELATED STANDARD & EQUIVALENT GRADE

China/GB 3077: 40CrNiMoA

Europe/EN10083: 39NiCrMo3/1.6510

Germany/DIN 17200: 36CrNiMo4/1.6511

WHAT IS AISI 9840 STEEL?

AISI 9840 steel is called Triple Alloy Steel because it has three main alloying elements: Cr-Ni-Mo.According to the SAE/AISI steel numbering designation system,we can clearly understand the meaning of 98XX from the table below.

| Type | AISI/SAE Designation | Chemical Composition |

Nickel-Chromium-Molybdenum Steel | 93XX | Ni 3.25%, Cr 1.20%, Mo 0.12% |

| 94XX | Ni 0.45%, Cr 0.40%, Mo 0.12% |

|

| 97XX | Ni 0.55%, Cr 0.20%, Mo 0.20% |

|

| 98XX | Ni 1.00%, Cr 0.80%, Mo 0.25% |

And the meaning of the last two “40” in the steel number 9840, it is very simple and clear to tell us that its average carbon content is 0.40% (0.38%-0.42%).

AISI 9840 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:850℃

- Forging Ratio:above 4:1

Post-Forging Treatment:AISI 9840 steel,as white-spot sensitive steel, is prone to cracks due to improper cooling after forged,so the recommended method is to arrange annealing heat treatment immediately after forging.

Advantages: First, it can eliminate processing stress and soften the material for further processing.Secondly, it can be used as a dehydrogenation heat treatment to prevent white spot defects and avoid material scrap.

AISI 9840 STEEL HEAT TREATMENT

- AISI 9840 Steel Annealing & Normalizing

Annealing and normalizing of AISI 9840 steel are used as conventional preparatory heat treatment and are often used in actual production. Let’s take a look at their main characteristics.

| AISI 9840 Annealing | AISI 9840 Normalizing | |

| Temperature,℃ | 840-880 | 890-920 |

| Cooling | Furnace Cooling | Air Cooling |

| Cooling Speed Rate | Much Slowly | Quickly |

| Grain size | Normal | Fine |

| Machinability | Good | Normal |

| Heat Treatment Cycle | Long time | Short time |

| Surface Hardness,HBW | ≤269 | / |

AISI 9840 Forged Round Steel For Normalizing

AISI 9840 Steel Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness | |

| Normalizing | 1280Mpa | 860Mpa | 12.2% | 36% | 16 | 363HBW |

| Annealing | 745Mpa | 470Mpa | 22% | 50% | 51 | 217HBW |

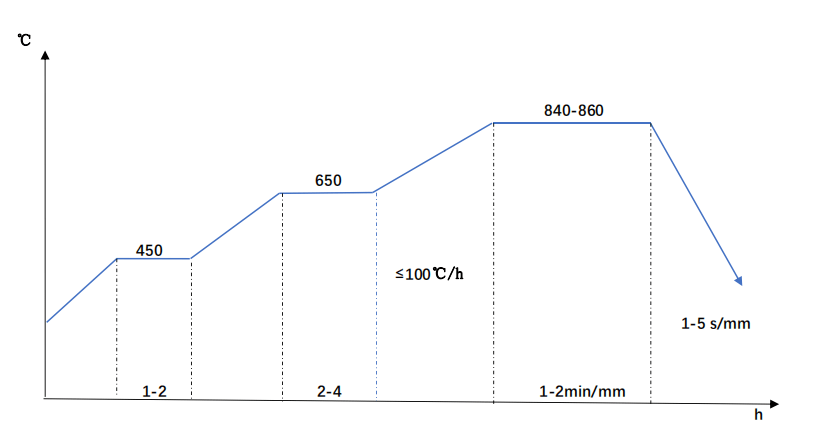

- AISI 9840 Steel Quenching & Tempering(Q&T)

For Cr-Ni-Mo triple low alloy steel,there is no doubt that the maximum performance of the material itself needs to be achieved through quenching and tempering heat treatment,so is AISI 9840 steel.

For AISI 9840 steel, the recommended quenching temperature is between 840-860ºC with quench medium oil,and the holding time depends on the thickness of the material.It can achieve hardness 55-59HRC after quenched.

AISI 9840 Steel Quenching Diagram

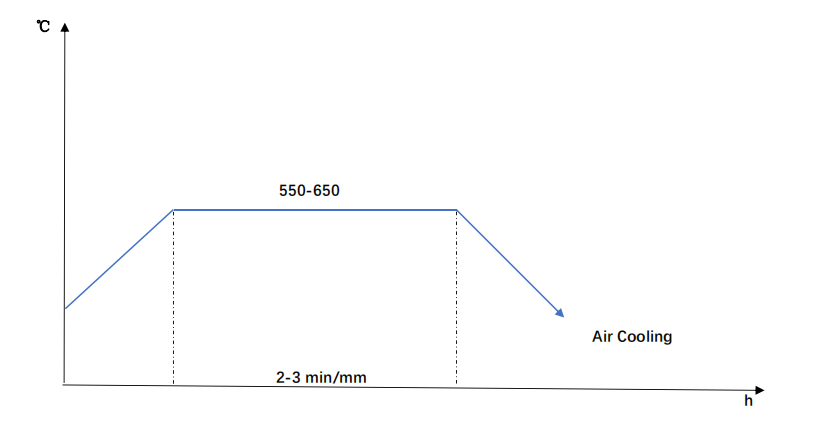

Tempering process for AISI 9840 steel should be followed after quenching immediately.The recommended tempering temperature is generally between 550-650°C with hardness range 27-34HRC.

AISI 9840 Steel Tempering Diagram

AISI 9840 Steel Tempering Temperature Vs Hardness

Grade | Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC | |

| 9840 | 850ºC | >55 | 55 | 54 | 49 | 44 | 38 | 34 | 30 | 27 |

AISI 9840 Steel Mechanical Property with Quenched and Tempered Condition

| Quenching Temperature | Quenching Medium | Tempering Temperature | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction % | Charpy Impact J |

850ºC | Oil | 400ºC | ≥1900 | ≥1700 | ≥5 | ≥20 | ≥30 |

| 600ºC | ≥1000 | ≥850 | ≥12 | ≥55 | ≥100 |