AISI 4130 steel (chromium-molybdenum alloy steel) is a classic grade in the American standard ASTM/AISI system.

The core advantage of 4130 steel lies in its excellent balance between high strength, good toughness, excellent fatigue performance, machinability, and weldability, while maintaining a relatively reasonable cost.

After quenching and tempering, 4130 steel can fully release its high strength potential while also possessing excellent impact resistance and fatigue resistance. With this stable and reliable “all-around” characteristic, 4130 steel has become the preferred structural material for the aerospace, oil and gas, and automotive industries.

AISI 4130 STEEL & EQUIVALENT GRADE CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 30CrMo | 0.26-0.33 | 0.17-0.37 | 0.4-0.7 | ≤0.03 | ≤0.03 | 0.8-1.1 | 0.15-0.25 |

| 25CrMo4 | 0.22-0.29 | ≤0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

| SCM430 | 0.28-0.33 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.3 |

AISI 4130 STEEL PHYSICAL PROPERTY

| Density,g/cm3 | 7.85 |

| Melting point,°C | 1432 |

| Poisson's ratio | 0.27-0.30 |

| Elastic modulus,Gpa | 200-210 |

| Thermal conductivity W/(m.K) | 46 |

| Specific heat capacity (20℃),J/(kg・K) | 460 |

| Linear expansion coefficient (20-100℃) | 11.2×10⁻⁶ /℃ |

| Resistivity,Ω・m | 0.22×10⁻⁶ |

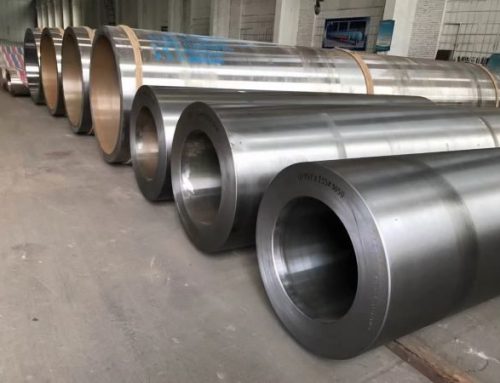

AISI 4130 STEEL FORGING

The four core aspects of AISI 4130 steel forging: temperature control, deformation control, cooling control, and microstructure control.

To avoid internal stress cracking caused by excessive temperature difference, AISI 4130 steel must be fully and thoroughly preheated between 650-750℃ before forging, and then rapidly heated to the forging temperature.

- Initial Forging Temperature: 1150-1180℃ (strictly prohibited from exceeding 1200℃ to avoid overheating and coarse grains)

- Final Forging Temperature: ≥850℃ (below this temperature, plasticity drops sharply,forced forging will inevitably lead to cracking.)

For AISI 4130 steel forgings, a multi-directional process combining upsetting and drawing shall be adopted, with strict control over the deformation per pass to ensure uniformity. The overall forging ratio must be maintained above 4:1 to fully break down the original as-cast structure. Additionally, heavy deformation at low temperatures, particularly below 900°C, must be strictly avoided.

After forging, air cooling is absolutely prohibited; AISI 4130 steel must be cooled slowly.

AISI 4130 STEEL HEAT TREATMENT

The heat treatment process for 4130 steel needs to be adjusted according to the final performance requirements. The core processes include annealing, normalizing, quenching and tempering.

- AISI 4130 Steel Normalizing & Annealing

Both normalizing and annealing processes for AISI 4130 steel are considered preparatory heat treatments, designed to provide a suitable microstructure and property basis for subsequent machining or final heat treatment.

| Process | Temperature | Cooling method | Process time | Microstructure | Final effect |

| Normalizing | 870-900°C | Air cooling | 2-3 days | Fine pearlite+ferrite | Grains refined, microstructure improved |

| Annealing | 830-850°C | Furance cooling | 5-7 days | Coarse pearlite+ferrite | Hardness reduced, stress relieved |

| Mechanical Property Reference | ||||||

| Process | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| Normalizing | 600-650MPa | 400-450MPa | 15-20% | 40-50% | 60-80J | 180-220HBW |

| Annealing | 500-550MPa | 300-350MPa | 20-25% | 50-60% | 80-100J | 130-170HBW |

- AISI 4130 Steel Final Heat Treatment:Quenching & Tempering

The final and most classic heat treatment process for 4130 steel is “quenching + tempering,” with the core objective of achieving comprehensive mechanical properties including high strength, good toughness, and fatigue resistance.

Different tempering temperatures represent different properties, among which the 4130 75K strength grade is widely used in engineering fields.

| AISI 4130 75K Process | ||||

| Process | Temperature | Cooling method | Microstructure | Material property |

| Quenching | 860-880°C | Water cooling | Martensite | Hard and brittle |

| Tempering | 650-680°C | Air cooling | Tempered sorbite | High strength and high toughness |

| AISI 4130 75K Mechanical Property | |||||

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Impact Charpy-V, -18ºC,J | Hardness HBW | |

| 75K | ≥ 655 | ≥ 517 | ≥ 17 | ≥ 42 | 197-235 |

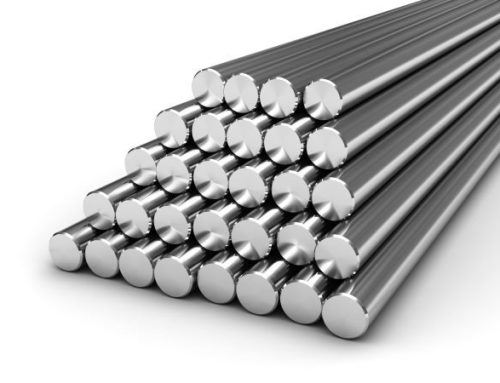

AISI 4130 STEEL SUPPLY FORM & SIZE & TOLERANCE

Are you in the market for high-performance 4130 steel? Whether you’re ready to source or just exploring, FUHONG is your trusted partner. As a Chinese First-Class Manufacturer, we focus on delivering top-tier 4130 steel products and customized, innovative solutions to fulfill your specific needs. With modern manufacturing technology and our seasoned professional team, we provide tailored 4130 steel solutions that align perfectly with your company’s operational goals.

Get in touch with us today to learn how FUHONG can resolve your 4130 steel challenges and elevate your production efficiency!

AISI 4130 steel Supplier,Stockist and Exporter,supplied with Round,Square,Flat,Block,and Shaft etc.

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ14-Φ260mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled