As ultra-high-strength low-alloy steel,36NiCrMo16 steel contains 1.8% Cr and 4% Ni elements as strengthening alloy elements as per EN10083 and EN10250 standard.

36NiCrMo16 steel has excellent hardenability due to its high nickel content and appropriate amount of chromium and molybdenum, and parts of general size can be hardened in air.In the quenched and tempered state, it has excellent strength, plasticity and toughness.

36NiCrMo16 steel is often used to make parts that require high strength, torsion and impact resistance, such as machine drive shafts, crankshafts, gears, worms, connecting rods, bolts, nuts, fasteners, etc.

36NiCrMo16 STEEL CHEMICAL COMPOSITION

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN10250 | 36NiCrMo16/1.6773 | 0.32-0.39 | ≤0.4 | 0.3-0.6 | ≤0.03 | ≤0.025 | 1.6-2.0 | 3.6-4.1 | 0.25-0.45 |

| EN10083 | 0.32-0.39 | ≤0.4 | 0.5-0.8 | ≤0.025 | ≤0.025 | 1.6-2.0 | 3.6-4.1 | 0.25-0.45 |

36NiCrMo16 STEEL RELATED STANDARD & EQUIVALENT GRADE

China | GB:35Cr2Ni4Mo

France | AFNOR:35NCD16

UK | BS:835M30

36NiCrMo16 STEEL FORGING

- Initial Forging Temperature:1200-1220℃

- Final Forging Temperature:850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Holding Time:Ensure that the material is fully and evenly heated,and the holding time should not be too long or too short.

- Forging Ratio:above 4:1

- Post-Forging Treatment:36NiCrMo16 steel is highly sensitive to white spots, and should be in the furnace for dehydrogenation treatment in time after forging.

36NiCrMo16 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 36NiCrMo16 Steel

- Ac1:670℃

- Ac3:795℃

Temperature Selection for Conventional Heat treatment for 36NiCrMo16 Steel

- Soft Annealing:650 – 690°C,Cooling in furnace,hardness below 269 HBW

- Normalizing:850-880°C

- Quenching:865-885°C,Medium:Water,Oil,Air

- Tempering:550-650°C

36NiCrMo16 Steel Mechanical Property in Quenched & Tempered condition

| Thickness of ruling section tR | |||||||||||||||||

| tR≤160mm | 160< tR ≤330mm | 330< tR ≤660mm | |||||||||||||||

| Re Min Mpa | Rm Min Mpa | A min,% | KV min,J | Re Min Mpa | Rm Min Mpa | A min,% | KV min,J | Re Min Mpa | Rm Min Mpa | A min,% | KV min,J | ||||||

| l | tr | l | tr | l | tr | l | tr | l | tr | l | tr | ||||||

| 800 | 1000 | 11 | 8 | 45 | 22 | 800 | 1000 | 11 | 8 | 45 | 22 | 800 | 1000 | 11 | 8 | 45 | 22 |

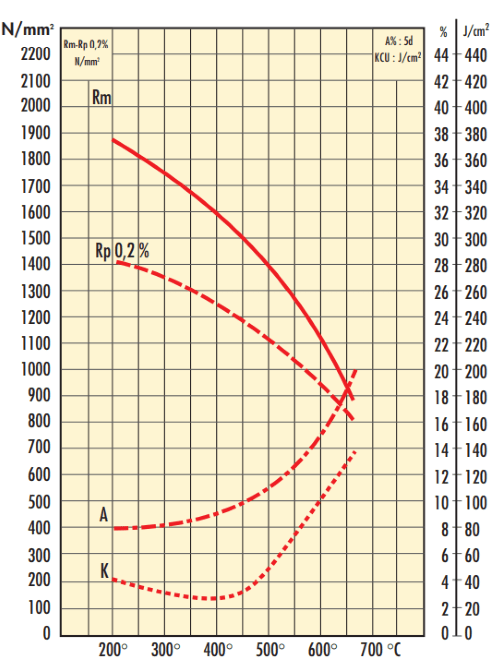

36NiCrMo16 steel Mechanical Property with Different Tempering temperature

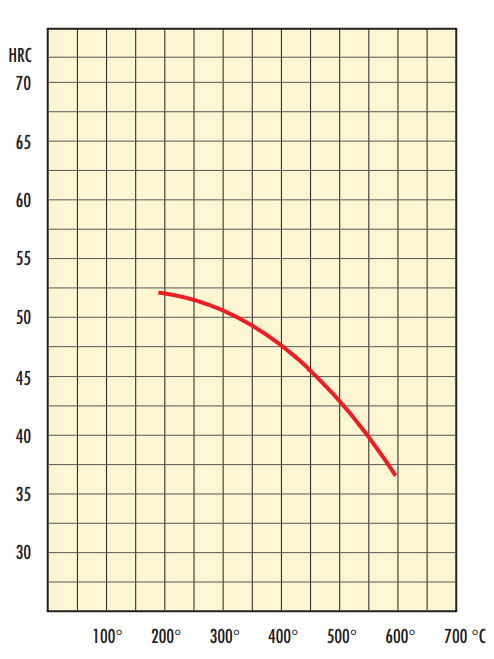

36NiCrMo16 steel Tempering temperature vs Hardness

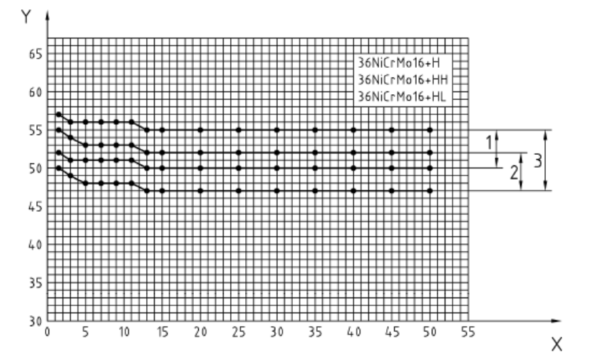

Jominy Quenching Test Curve For 36NiCrMo16 Steel

Quenching at 850°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

1: HH level

2: HL level

3: H level

| HRC-mm | Type | 1.5 | 3 | 6 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| MIN | +H | 50 | 49 | 48 | 48 | 48 | 48 | 47 | 47 | 47 | 47 | 47 | 47 | 47 | 43 | 43 |

| MAX | 57 | 56 | 56 | 56 | 56 | 56 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 54 | |

| MIN | +HH | 52 | 51 | 51 | 51 | 51 | 51 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| MAX | 57 | 56 | 56 | 56 | 56 | 56 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| MIN | +HL | 50 | 49 | 48 | 48 | 48 | 48 | 47 | 47 | 47 | 47 | 47 | 47 | 47 | 47 | 47 |

| MAX | 55 | 54 | 53 | 53 | 53 | 53 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 52 |

WHAT WE SUPPLY FOR 36NiCrMo16 STEEL

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

36NiCrMo16 Steel Shaft Quenching