DIN41Cr4/1.7035 Steel is one of the most widely used medium carbon quenched and tempered steels in the machinery manufacturing industry as per EN10083 standard.After proper heat treatment, it has good comprehensive mechanical properties, such as good toughness, plasticity and wear resistance, low temperature impact toughness and low notch sensitivity.

The hardenability of 41Cr4 steel is good,which is higher than that of C45 steel.41Cr4 steel is suitable for surface hardening such as high frequency quenching and flame quenching.After quenching and tempering (or normalizing), good machinability can be obtained.It is usually supplied in quenched and tempered condition

41Cr4/DIN 1.7035 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ350mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

41Cr4/DIN 1.7035 STEEL CHEMICAL COMPOSITION

| Standard | Grade | C | Si | Mn | P | S | Cr |

| EN10083 | 41Cr4/1.7035 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | ≤ 0.025 | ≤ 0.035 | 0.9-1.2 |

| ASTM A29 | 5140 | 0.38-0.43 | 0.15-0.35 | 0.7-0.9 | ≤ 0.035 | ≤ 0.04 | 0.7-0.9 |

41Cr4/DIN 1.7035 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA/GB 3077:40Cr

USA/ASTM A29:5140

JAPAN/ JIS G4104:SCr440

UK/BS970:530M40

41Cr4/DIN 1.7035 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:850℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:41Cr4 steel should be slowly cooling in sand.

41Cr4/DIN 1.7035 STEEL HEAT TREATMENT

41Cr4/1.7035 Steel Normalizing & Annealing

| 41Cr4/1.7035 Annealing | 41Cr4/1.7035 Normalizing | |

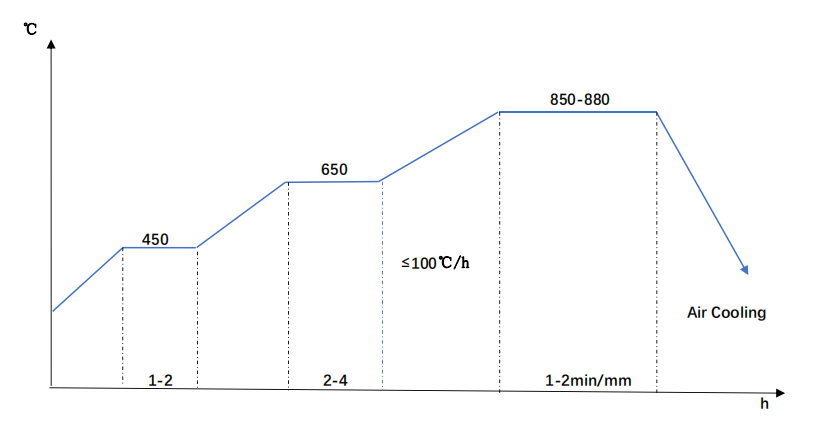

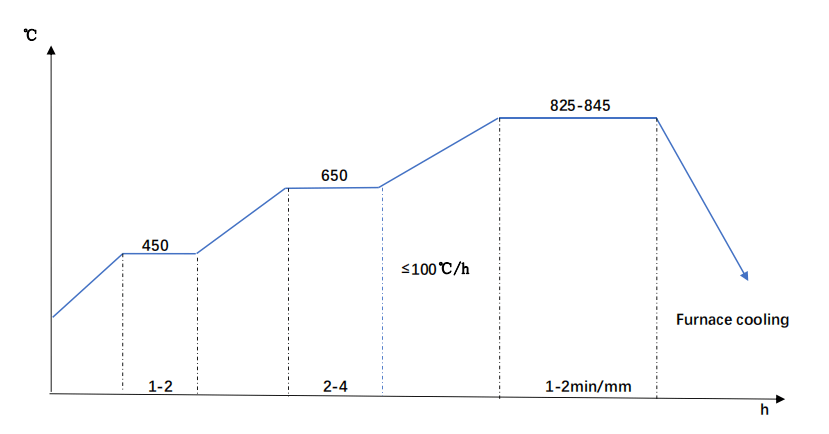

| Temperature,℃ | 825-845 | 850-880 |

| Holding time | Depend on material thickness | Depend on material thickness |

| Cooling | Furnace Cooling | Air Cooling |

| Cooling Speed Rate | Much Slowly | Quickly |

| Grain size | Normal | Fine |

| Deformation | Large | Large |

| Machinability | Good | Normal |

| Productivity | Relatively low | High |

| Surface Hardness,HBW | ≤250 | ≤207 |

41Cr4/1.7035 Steel Mechanical Properties in N & A condition

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness | |

| Normalizing | 795Mpa | 470Mpa | 22.7% | 59% | 38 | 229HBW |

| Annealing | 570Mpa | 295Mpa | 28.6% | 57% | 41 | 167HBW |

41Cr4 Steel Normalizing Diagram

41Cr4 Steel Annealing Diagram

41Cr4/1.7035 Steel Quenching & Tempering(Q&T)

Process Details

- Quenching Temperature:830-860ºC

- Quenching Medium: Oil

- TemperingTemperature:400-600ºC

- Cooling Medium:Air

41Cr4/1.7035 Steel Tempering Temperature Vs Hardness

| Grade | Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC | |

| 41Cr4 | 850ºC | >55 | 55 | 53 | 51 | 43 | 34 | 32 | 28 | 24 |

41Cr4/1.7035 Steel Mechanical Property with Quenched and Tempered Condition

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| ≥1000 | ≥800 | ≥9 | ≥45 | ≥60 |

41Cr4/1.7035 Steel Nitriding

41Cr4 belongs to nitridable steel, and the elements it contains are conducive to nitriding.Higher surface hardness can be obtained after nitriding treatment.The hardness of 41Cr4 steel(Q&T condition) can reach up to 72~78HRA after nitriding treatment, and the hardness of the core reaches 43~55HRC.

41Cr4 steel Nitriding process route:

Forging – Annealing – Roughing – Quenching & Tempering – Finishing – Stress relief – Rough grinding – Nitriding – Fine grinding

Because the nitrided layer is thin and brittle, a high-strength core structure is required, so 41Cr4 steel should be quenched and tempered first to obtain tempered sorbite to improve the mechanical properties of the core and the quality of the nitrided layer.

41Cr4/DIN 1.7035 STEEL APPLICATION

After quenching and tempering, 41Cr4 steel is used to manufacture mechanical parts under medium load and medium speed, such as steering knuckles, rear half shafts of automobiles, and gears, shafts, worms, spline shafts, and top sleeves on machine tools.

- Quenching with medium temperature tempering

Manufacture of parts subjected to high load, impact and moderate speed work, such as gears, spindles, oil pump rotors, sliders, collars, etc

- Quenching with low temperature tempering

Manufacture of parts with heavy load, low impact and wear resistance, and the solid thickness of the section is less than 25mm, such as worm, spindle, shaft, collar, etc.

- QT & High frequency surface hardening

Manufacture of parts with high surface hardness and wear resistance without great impact, such as gears, sleeves, shafts, main shafts, crankshafts, mandrels, pins, connecting rods, screws, nuts, intake valves, etc.

In addition, 41Cr4 steel is suitable for the manufacture of various transmission parts for carbonitriding treatment, such as gears and shafts with large diameters and good low temperature toughness.