34CrNiMo6 Steel is a typical high-strength alloy structural steel in the European standard. As a medium carbon alloy steel containing Molybdenum, Chromium and Nickel,it is considered to be one of the most popular steels in Europe.

In the quenched and tempered condition, the performance characteristics of 34CrNiMo6 steel can be maximized,that is, High Strength, High Toughness and Good Hardenability.This is why you will find this type of steel often used in high strength requirements in European countries.

Due to its excellent comprehensive mechanical properties,34CrNiMo6 steel is widely used in the manufacture of important parts such as train axles, mechanical main shaft parts, wind power shafts, engine camshafts and connecting rods,etc.

34CRNIMO6 STEEL CHEMICAL COMPOSITION

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| EN 10083 | 34CrNiMo6 /DIN 1.6582 | 0.30-0.38 | ≤0.4 | 0.5-0.8 | ≤0.025 | ≤0.035 | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 |

| EN 10250 | 0.30-0.38 | ≤0.4 | 0.5-0.8 | ≤0.035 | ≤0.035 | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | |

| SEW 550 | 0.30-0.38 | ≤0.4 | 0.4-0.7 | ≤0.035 | ≤0.035 | 1.4-1.7 | 0.15-0.30 | 1.4-1.7 | |

| DIN 17200 | 0.30-0.38 | ≤0.4 | 0.4-0.7 | ≤0.035 | ≤0.03 | 1.4-1.7 | 0.15-0.30 | 1.4-1.7 |

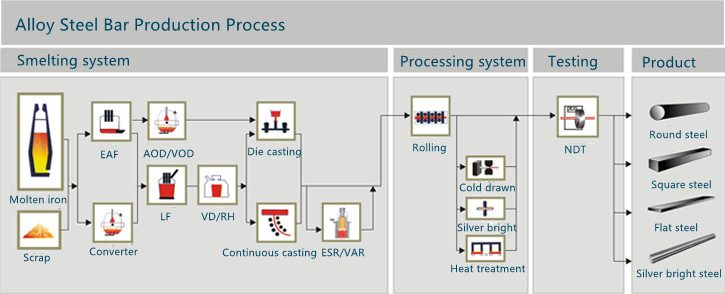

34CRNIMO6 STEEL PRODUCTION PROCRSS

- 34CrNiMo6 Steel Heat Treatment Production Line

Automatic intermediate frequency quenching production line

- Equipped with 5 automated production lines

- Heat treatment diameter: Dia14-130mm

- Length limit: 3,000-9,000mm

- Automatic straightening machine

Conventional quenching and tempering production line

- Equipped with Box type trolley furnaces

- Loading limit:30 tons

- Length limit: below 13,000mm

- 1000 tons Straightening machine

- 34CrNiMo6 Steel Machining

- 34CrNiMo6 Steel Dimensional inspection

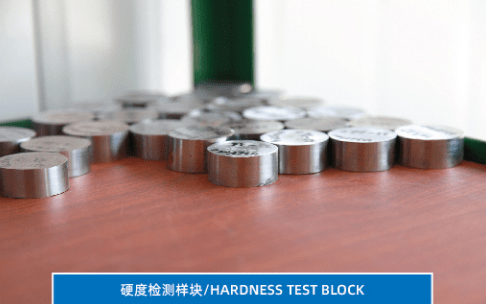

- 34CrNiMo6 Steel Hardness check

- 34CrNiMo6 Steel Mechanical property testing

34CrNiMo6 Steel Mechanical property

| Size(mm) | Rm(Mpa) | Rel(Mpa) | A5(%) | Z(%) | Aku(J) |

| Φ60 | 1150 | 1060 | 17 | 62 | 92 |

| Φ200 | 930 | 825 | 21 | 56 | 85 |

| Φ350 | 900 | 780 | 17 | 62 | 100 |

| Φ430 | 825 | 650 | 17 | 55 | 86 |

| Φ575 | 785 | 590 | 20 | 50 | 80 |

Remark:The above data is the real test data of the laboratory, for your reference only

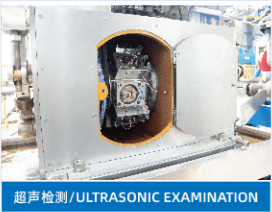

- Automatic Flaw Detection System

14-Channels Ultrasonic Testing

- Four probes in 4 Channels:Detecting longitudinal cracks inside and outside the bar in two directions

- Six probes in 6 Channels:Detecting transverse cracks inside and outside the bars

- Four probes in 4 Channels:Detecting internal defects in the bars

3-Channels Eddy Current Testing

Detection method of probe rotation,Detecting surface and near surface defects.

Detection diameter:Ф17mm~Ф80mm

Detection length:3-9m

Straightness:≤1.5mm/m

Detect applicable materials:High strength steel,Carbon tool steel,Carbon structural steel,Alloy structural steel,Tool steel,Spring steel,Bearing steel,High-speed steel,Stainless steel

Defect detection capability

The following comparative defects can be detected in the online state.

Center cross hole:Ф0.8x15mm

2mm horizontal hole under the skin:Ф0.5×12.7mm

Surface groove:depth x width x length 0.1×0.1x10mm

- 34CrNiMo6 Steel Production Process Flow Chart

STRATEGIC PARTNERS

WHAT WE SUPPLY FOR 34CRNIMO6 STEEL

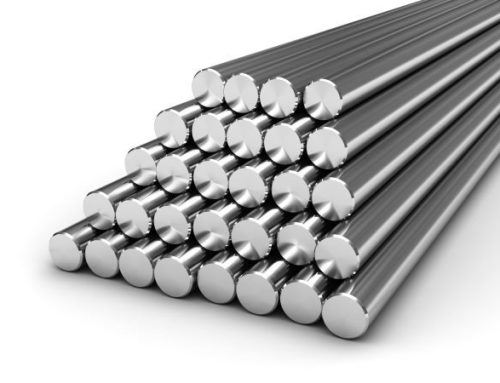

- Dia 16-300mm daily inventory wih 800+tons round bars

- Annealed/Q&T(pre hardened)condition for 5 days delivery available

- Bright steel with QT condition for 10 days delivery available

- Cut to length service available

- Daily stock ingots to meet customer urgent order needs

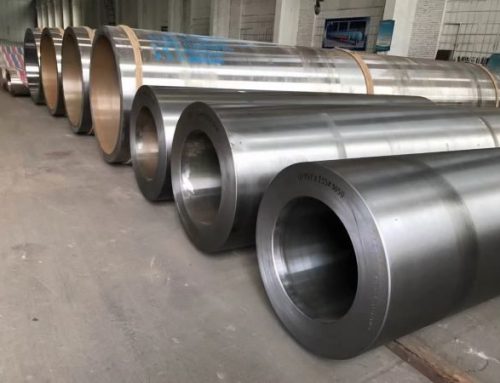

- Dia 80-1000mm full size forging available

- Square/Flat/Blocks/Shafts customized production

- One-stop machining service

- Guaranteed inspection and testing