How to Detect the Authenticity of 4140 Steel? Four Simple Methods to Avoid Purchasing Pitfalls

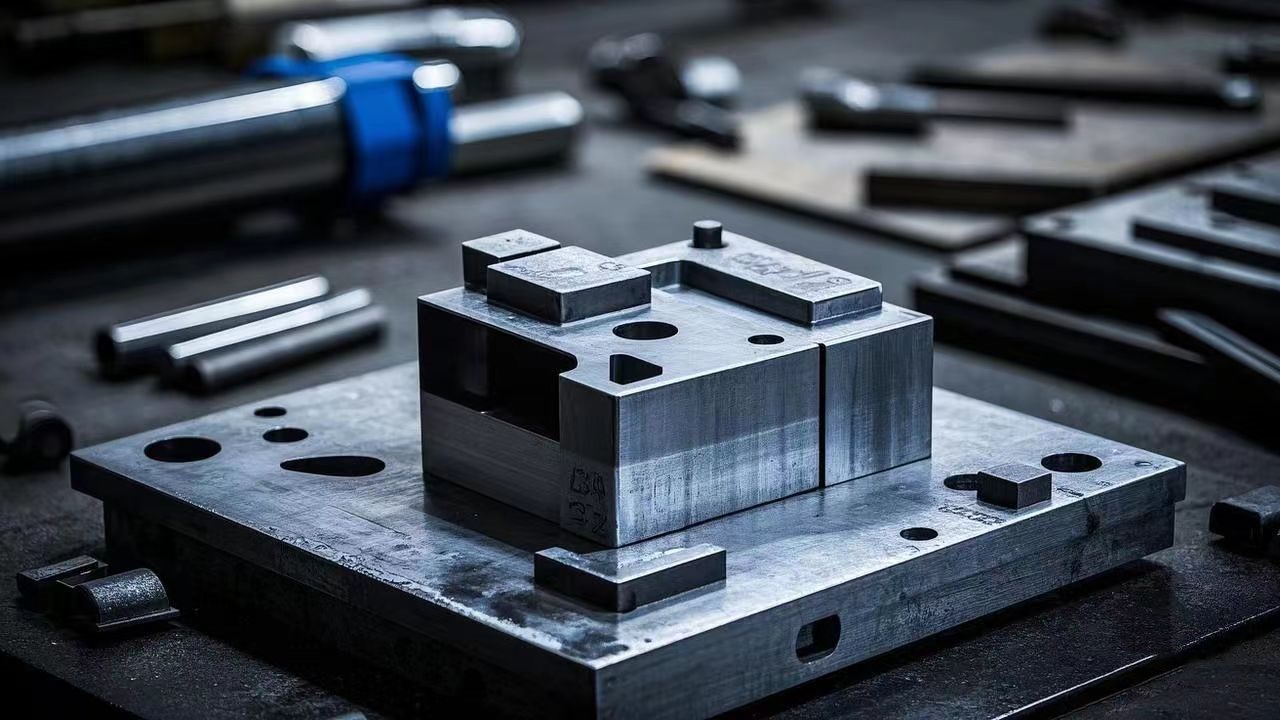

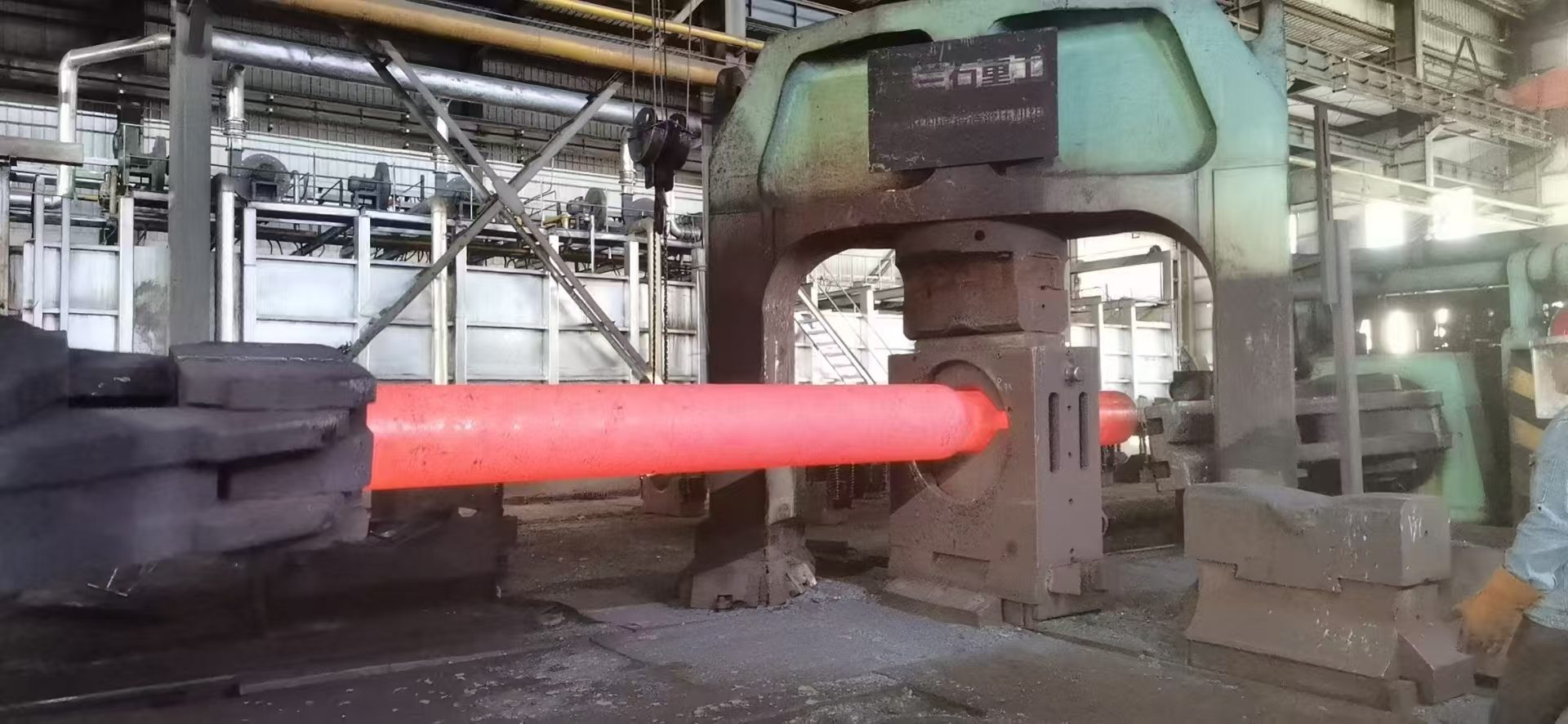

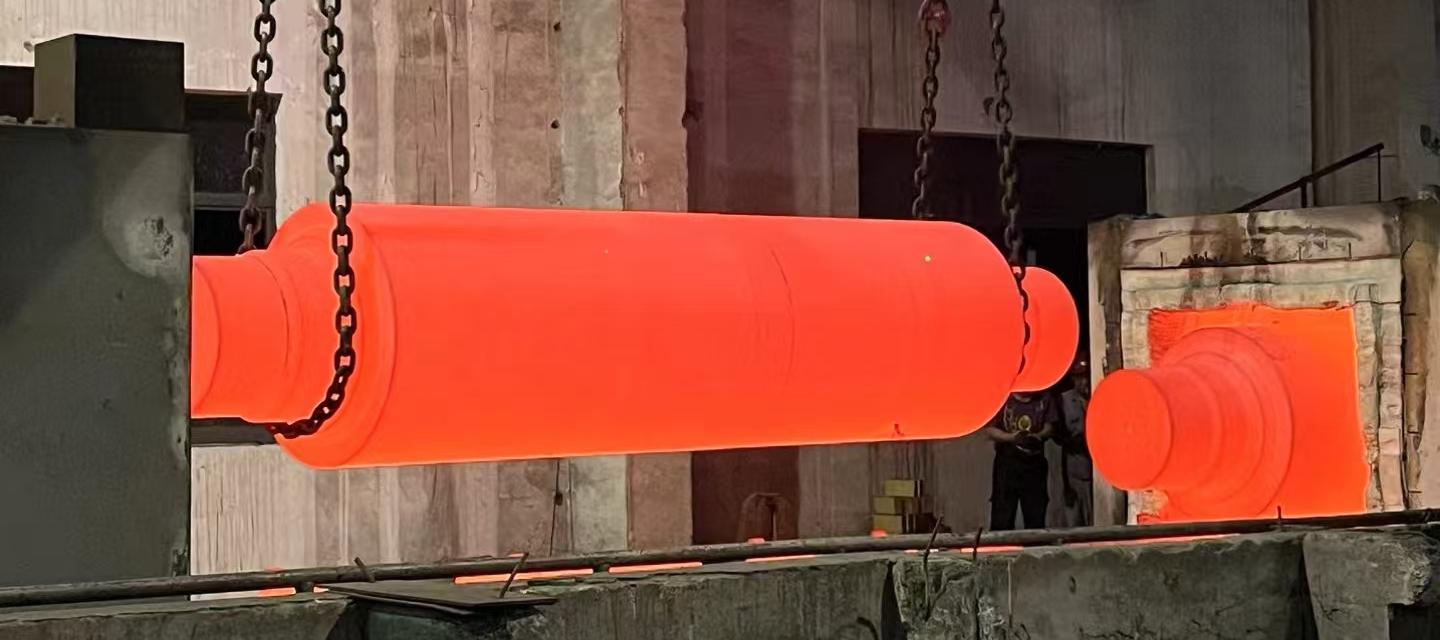

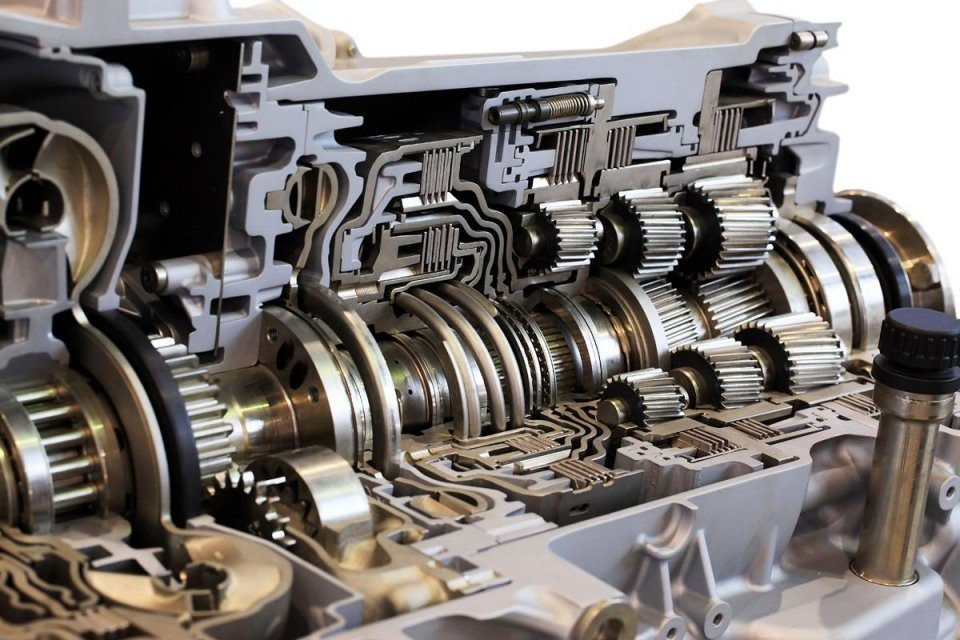

Why is It So Important To Detect The Authenticity of 4140 Steel? In industries such as machinery manufacturing and mold processing, the use of counterfeit or substandard 4140 steel may lead to part breakage, equipment downtime, and even safety accidents. Real case: A factory used inferior 4140 steel to manufacture gear shafts, which cracked [...]