DIN 1.2311 (40CrMnMo7) is a German standard pre-hardened plastic mold steel, corresponding to AISI P20.

As one of the most widely used plastic mold steels globally, 1.2311 steel is renowned for its pre-hardened supply (28-34 HRC), high purity, uniform microstructure, and excellent machinability. It balances strength, toughness, machinability, and cost, making it particularly suitable for mold manufacturing that demands high efficiency and consistent quality.For applications requiring higher polishing performance or toughness, consider upgrading to nickel-containing 1.2738 (718) steel; for mass production of simple molds, the easy-to-mute properties of 1.2312 (P20+S) offer a cost advantage.

1.2311 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 1.2311 | 0.35-0.45 | 0.2-0.4 | 1.3-1.6 | ≤0.03 | ≤0.03 | 1.8-2.1 | 0.15-0.25 |

1.2311 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA-GB/T 1299:3Cr2Mo

USA-ASTM A681 :P20

1.2311 STEEL PHYSICAL PROPERTY(20°C)

- Density: 7.85 g/cm³

- Coefficient of thermal expansion: 12.1 × 10⁻⁶/K

- Thermal conductivity: 45 W/(m·K)

- Elastic modulus: 210 GPa

- Poisson’s ratio: 0.3

QUICK FAQS FOR 1.2311 STEEL

Does 1.2311 steel require heat treatment?

The biggest advantage of 1.2311 steel is that it is supplied pre-hardened, allowing for direct machining without heat treatment.

1.2311 steel has already undergone quenching and tempering at the factory, typically achieving a hardness of 290-330 HBW (approximately 30-36 HRC). Therefore, it can be directly machined without secondary heat treatment, avoiding the risk of deformation during heat treatment and shortening the manufacturing cycle.

Is 1.2311 steel easy to machine?

In pre-hardened condition, 1.2311 steel is still suitable for all conventional processes such as turning, milling, drilling, and grinding.

How is the polishing performance of 1.2311 steel?

1.2311 steel has excellent polishing performance and can be polished to mirror level (such as A1-A3 grade), meeting the requirements of high-gloss surface molds.

Is 1.2311 steel easy to weld?

Compared to high-hardness tool steels, 1.2311 steel is relatively easy to weld and repair, but preheating and post-weld treatment specifications still need to be followed.

Is 1.2311 steel tough?

Within its pre-hardening hardness range, it exhibits good toughness and can withstand impact loads during mold assembly and normal production.

How corrosion resistant is 1.2311 steel?

Belonging to the chromium-molybdenum alloy steel category, 1.2311 steel has moderate corrosion resistance, better than carbon steel but less than stainless steel. In humid environments or when processing corrosive plastics (such as PVC), the surface may require chromium or nickel plating for protection.

1.2311 STEEL FORGING

- Initial forging temperature: 110-1150℃,Heating must be done evenly and slowly to avoid cracking due to thermal stress. Do not exceed 1200°C to prevent overheating.

- Final forging temperature: ≥850℃,Below this temperature, the plasticity of 1.2311 steel decreases and its resistance to deformation increases sharply; continued forging will lead to internal cracks.

- Forging Ratio:above 4:1

- Cooling method: 1.2311 steel should be cooled as slowly as possible in still air or in sand after forged.

- Post-Forging Treatment:It is recommended to perform annealing heat treatment on 1.2311 steel before rough machining.

1.2311 STEEL HEAT TREATMENT

1.2311 Steel Annealing

- Process: Heat to approximately 780-800°C, hold at that temperature, then furnace cool at a rate of ≤20°C/hour to approximately 500°C, followed by air cooling.

- Purpose: To reduce hardness (below 220 HBW) to facilitate subsequent rough machining; to achieve a uniform microstructure in preparation for final quenching.

1.2311 steel pre-hardening heat treatment – Quenching & Tempering

- Quenching: Heat to 830-850°C, fully austenitize, and then quench in oil or in a protective atmosphere (high-pressure gas quenching). 1.2311 steel has excellent hardenability, and good hardness can be achieved even in large sections.

- Tempering: Depending on the desired hardness, perform high-temperature tempering in the range of 550-650°C. Tempering is crucial for obtaining the final properties and must be performed thoroughly (typically holding for 2 hours per 25 mm thickness), followed by air cooling. This will result in a uniform tempered sorbite structure with a hardness of 290-330 HBW.

1.2311 Steel Mechanical Property in pre-hardening condition

- Tensile strength: 900-1100 MPa

- Yield strength: 800-950 MPa

- Elongation: 12-15%

- Reduction of area: 45-55%

- Impact toughness: 40-60 J

- Hardness: 28-34 HRC (280-325 HB)

1.2311 Steel vs. Similar Steel

| Properties | 1.2311 (P20) | 1.2312 (P20+S) | 1.2738 (718) |

| Sulfur content | ≤0.03% | 0.05-0.1% | ≤0.03% |

| Machinability | Good | Excellent | Good |

| Polishability | Excellent | Good | Excellent |

| Hardness range | 28-34 HRC | 28-34 HRC | 30-36 HRC |

| Toughness | Good | Medium | Excellent |

| Applicable Scenarios | General plastic molds | Mass production simple molds | High-requirement transparent parts molds |

Compared to higher-end mold steels: Compared to hardened steels (such as 1.2344/H13 hot work steel, 1.2083/420 stainless steel), 1.2311 has lower hardness, wear resistance and corrosion resistance, but its pre-hardened (no need for further heat treatment), high toughness and easy machinability are huge advantages.

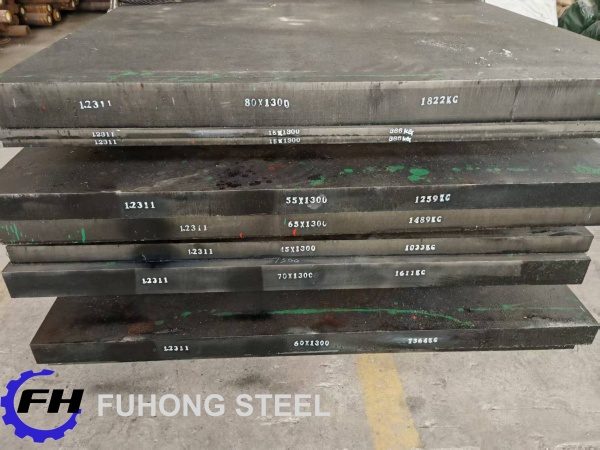

1.2311 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ61-Φ800mm

Hot Rolled Round bar:Φ14-Φ130mm

Hot Forged Square bar: Max Thickness:400mm

Flat bar/Blcoks:Thickness :8-400mm ,Width:210-2200mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |