Whether 4130 steel is quenched and tempered after normalizing or not mainly affects the performance of the material. The performance gap mainly depends on the initial state of the material and the degree of optimization of the processing technology. The following analyzes the performance differences from different aspects:

1. Microstructure & Uniformity

- 4130 steel normalizing + quenching and tempering:

Normalizing provides a more uniform matrix for subsequent quenching and tempering by refining the grains and homogenizing the structure. Fine martensite is formed during quenching, and uniform tempered troostite is obtained after tempering, with fine and uniform grains. - 4130 steel direct quenching and tempering:

If the raw material has banded structure, coarse grains or residual stress, quenching may lead to uneven structure, and the performance anisotropy is obvious after tempering.

2. Comparison of Mechanical Properties

- Strength and hardness:

The strength (tensile strength, yield strength) and hardness of both after quenching and tempering are similar, because the tempering temperature of quenching and tempering dominates the final strength. Normalizing pretreatment may slightly increase the strength (within about 50 MPa), but the difference is usually not significant. - Toughness:

The impact toughness (especially low-temperature toughness) of normalizing + quenching and tempering is better. For example, the impact energy may increase by 20%~30% because the fine grains effectively hinder crack propagation. - Fatigue performance:

Uniform and fine structure can improve the fatigue limit, and the fatigue life of normalizing + quenching and tempering may be 10%~20% higher than that of direct quenching and tempering.

3. Process Stability & Reliability

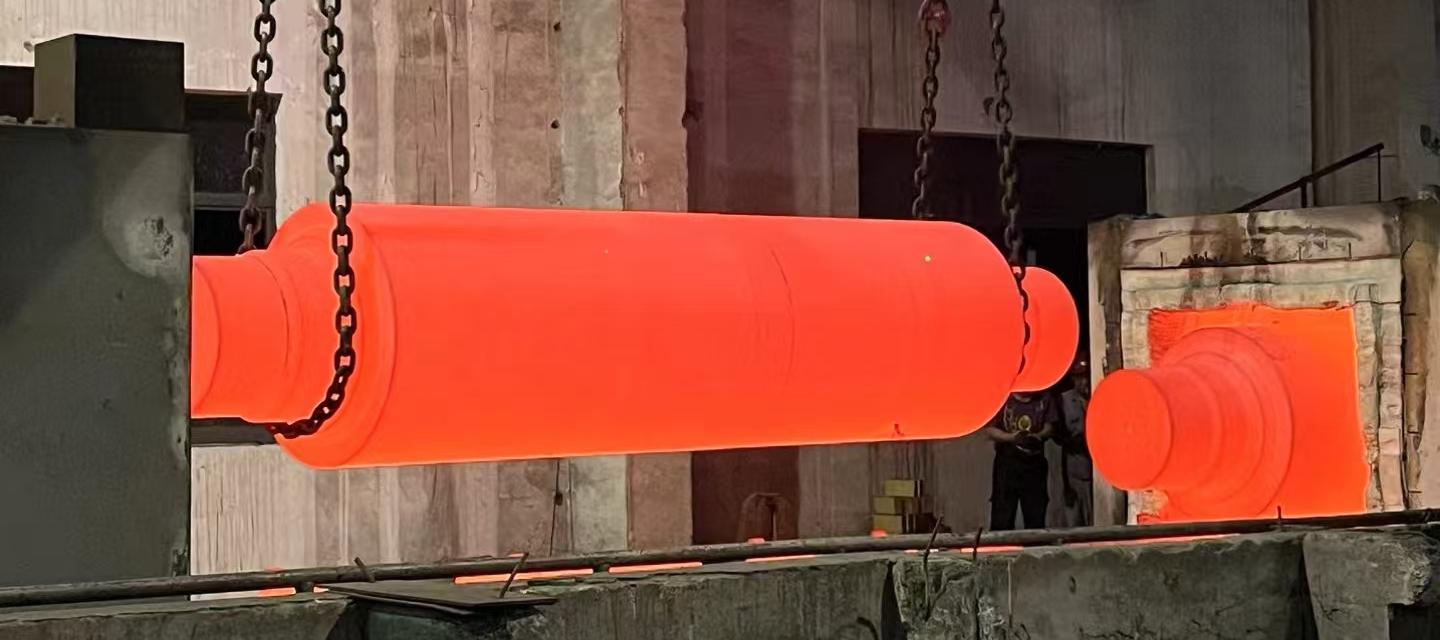

- Normalizing + quenching and tempering:

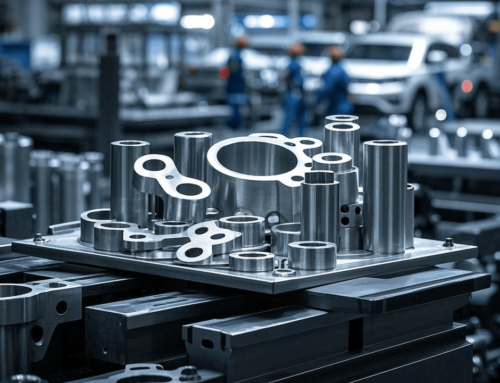

Reduce the risk of quenching cracking, improve processing performance, reduce anisotropy, and are suitable for high-stress or complex-shaped parts. - Direct quenching and tempering:

If the original structure is poor, it may lead to large performance fluctuations, especially in thick sections or complex parts, where soft spots or stress concentrations are prone to occur.

4. Typical Data Reference

| Processing process | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Impact energy (J, -20°C) |

| Normalizing + quenching and tempering | 850~950 | 700~800 | 15~20 | 40~50 |

| Direct quenching and tempering (uneven structure) | 800~900 | 500~750 | 10~15 | 25~35 |

Note: The above data are indicative values, which need to be determined according to specific process parameters and material batches.

5. Conclusion

- Key gaps:

Normalizing pretreatment significantly improves toughness, fatigue performance and microstructure uniformity, especially when the raw material is in poor condition. - Applicable scenarios:

– High reliability parts (such as aviation and pressure-bearing parts) must be normalized + tempered.

– If the raw material structure is uniform (such as controlled rolling and controlled cooling), direct tempering may be sufficient, but strict inspection is required.

It is recommended to determine the specific process path through metallographic analysis and mechanical testing to ensure optimal performance.