AISI 4140 low-alloy chromium-molybdenum steel is widely used in the oil and gas, aviation, and heavy equipment industries for its excellent hardenability and comprehensive mechanical properties. Through quenching and tempering (quenching followed by high-temperature tempering), it can be developed into a multi-grade strength system, with the 80 ksi (550 MPa) and 110 ksi (758 MPa) yield strength grades being the most representative. This article systematically compares these two grades in terms of mechanical properties, microstructure, toughness, and typical applications, providing a basis for material selection and failure risk control.

4140 Steel Mechanical Properties Comparison: 80 KSI vs 110 KSI

Heat Treatment Process:

- 80 KSI: 850°C oil quench + 650–680°C high-temperature tempering

- 110 KSI: 850°C oil quench + 550–600°C medium-temperature tempering

The difference in tempering temperature directly determines the trade-off between strength and toughness.

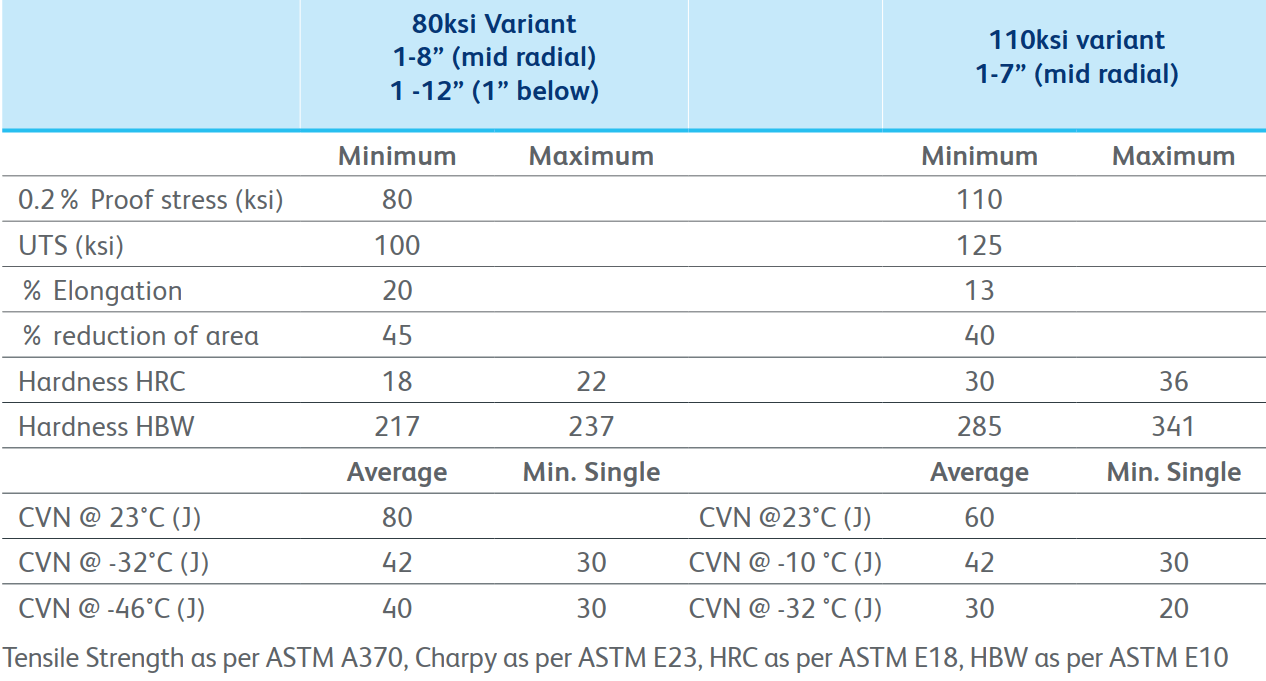

| Index | 80 KSI | 110 KSI | Differences |

| Yield Strength | ≥ 550 MPa | ≥ 758 MPa | 110 KSI: Approximately 34–55% improvement |

| Tensile Strength | 690–750 MPa | 862–1030 MPa | 110 KSI: Approximately 38–66% improvement |

| Hardness | 18–22HRC | 30–36HRC | Approximately 10 HRC difference, resulting in significant improvement in wear resistance |

| Elongation | ≥ 20% | ≥ 13% | 80 KSI: Higher plastic reserve, better formability |

| Reduction of Area | ≥ 40% | ≥ 30% | 80 KSI is less susceptible to brittle fracture |

| Room-temperature Charpy V impact energy | 50–80 J | 25–40 J | 80 KSI toughness is more than double that of 110 KSI |

| Fracture toughness K_IC | 90–110 MPa√m | 60–80 MPa√m | High-temperature tempering spheroidizes carbides in 80 KSI, inhibiting crack growth |

4140 Steel Microstructural Differences: 80 KSI vs 110 KSI

- 80 KSI: After quenching and tempering, tempered sorbite is formed. Carbides are evenly distributed in the ferrite matrix in a spherical shape, allowing for easy dislocation movement, resulting in excellent plasticity and toughness.

- 110 KSI: After quenching and tempering, tempered troostite is formed. Carbides are finely dispersed in the martensite matrix, hindering dislocation movement. This significantly increases strength but reduces toughness.

4140 Steel Application Comparison:80 KSI vs 110 KSI

| Level | Typical Applications | Key Design and Failure Control Points |

| 80 KSI | Subsea connectors, casing hangers, hydraulic connecting rods, high-strength bolts for construction, mold and die sets | Overload plastic deformation and low-temperature impact fracture must be prevented; Weldability and good cold working performance are available. |

| 110 KSI | Aviation landing gear, heavy-duty gears, downhole motor housings, drill collars, high-load drive shafts | Fatigue cracking and overload brittle fracture must be prevented; Surface hardening (such as nitriding and shot peening) is recommended to improve fatigue life. |

Summary

80 KSI and 110 KSI grades complement each other in the strength-toughness coordinate system:

- When impact resistance, fatigue crack arrest, or weld cold working are primary design objectives, 80 ksi is preferred.

- When the structure must withstand high static loads and high contact stresses, and fatigue can be suppressed through surface hardening, 110 ksi is more suitable.

Properly matching the strength grade, heat treatment process, and subsequent surface treatment is key to ensuring the long-term safe and reliable operation of 4140 steel under harsh service conditions.