In the field of mechanical manufacturing, carburizing steel is the core material of high-load parts such as gears, bearings, and transmission shafts. Among the many carburizing steel grades, 8620 steel (SAE/AISI 8620) is known as the “king of carburizing steel” for its excellent balance of comprehensive performance. Behind this title is its unique advantages in composition design, process adaptability and industrial application.

1. Composition Advantage: Alloy Design For Carburizing

8620 steel belongs to nickel-chromium-molybdenum low alloy steel, and its typical chemical composition is:

- Carbon (C): 0.18-0.23% —— Low carbon matrix ensures core toughness and provides a “blank canvas” for carburizing.

- Nickel (Ni): 0.40-0.70% —— Improve hardenability, refine grains, and enhance impact resistance.

- Chromium (Cr): 0.40-0.60% —— Promote surface carbon absorption and form high-hardness carbides.

- Molybdenum (Mo): 0.15-0.25% —— Inhibit temper brittleness and improve high-temperature strength.

This combination of ingredients makes it form a “hard surface and tough core” structure after carburizing:

- Surface (carburized layer): carbon content can reach 0.8-1.2%, hardness can reach HRC 58-62, and wear resistance is excellent;

- Core: maintain the high toughness and fatigue resistance of low-carbon steel, and avoid brittle fracture.

2. The “Golden Partner” of Carburizing Process

Carburizing process (Carburizing) significantly improves wear resistance by penetrating carbon atoms into the steel surface. The compatibility of 8620 steel and carburizing technology is perfect:

1.8620 steel has high carburizing efficiency

The chromium element accelerates the diffusion of carbon atoms, and the carburizing time is shortened by 10%-15% compared with ordinary low-carbon steel, reducing energy consumption and cost.

2. The carburized layer of 8620 steel is uniform and controllable

The addition of nickel and molybdenum refines the grains, ensures the depth of the carburized layer (usually 0.5-2.0mm) and the smooth transition of the hardness gradient, and reduces stress concentration.

3. 8620 steel has strong deformation resistance

After heat treatment, it has excellent dimensional stability, especially suitable for parts with strict tolerance requirements such as precision gears.

Case comparison: After carburizing 8620 steel, the life of a certain automobile gearbox gear increased by 30% compared with 20CrMnTi steel, and there was no tooth surface peeling problem.

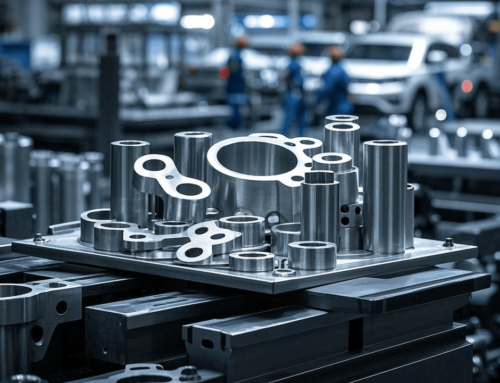

3. Irreplaceable Industrial Application Scenarios

The “king status” of 8620 steel is based on its wide application in the following key areas:

1. Automobile industry

- Gearbox gears: bear high-frequency impact loads, relying on the “hard surface and tough core” structure of 8620 steel;

- Differential parts: wear resistance after carburizing meets the driving requirements of more than 100,000 kilometers;

- New energy vehicle drive shaft: under the trend of lightweight, its high strength-to-weight ratio becomes the first choice.

2. Heavy machinery

- Mining machinery gears: in dust and high-load environments, the fatigue resistance of 8620 steel significantly extends the maintenance cycle;

- Engineering machinery bearings: the carburized layer depth can reach 1.5mm, which is suitable for extreme working conditions.

3. Aerospace

Used for landing gear transmission parts, vacuum carburizing technology is used to achieve an oxidation-free surface to ensure safety and reliability.

4. “King’s Battle” with Similar Materials

Despite the existence of other carburizing steels (such as 20CrMnTi, SAE 4320, etc.), 8620 steel still wins with the following advantages:

| Comparison dimensions | 8620 | 20CrMnTi |

| Core toughness | Very high (nickel element support) | Medium |

| Carburized layer uniformity | Excellent (grain refinement) | Good |

| High temperature performance | Excellent (molybdenum element resistance to tempering softening) | General |

| Cost | Medium-high | Low |

Conclusion: In the field of high-end manufacturing, 8620 steel dominates with “performance first”; in cost-sensitive scenarios, materials such as 20CrMnTi still have a certain market.

5. Future Challenges and Evolutionary Directions

Despite its stable position, 8620 steel also faces new challenges:

- Environmental pressure: Carbon emission problems in traditional gas carburizing promote green processes such as vacuum carburizing and plasma carburizing;

- Additive manufacturing: Can 3D printing technology break through the bottleneck of interlayer bonding strength of 8620 steel?

- Intelligent upgrade: AI algorithm optimizes carburizing process parameters to achieve zero-defect production.

Summary

8620 steel’s title of “King of Carburizing Steel” comes from the perfect closed loop of its composition, process and application. Whether it is traditional fuel vehicle gears or aerospace precision parts, it has always been an irreplaceable “ace material” in the hearts of engineers with its characteristics of “hard but not brittle, strong and durable”. With the advancement of technology, this “king” may continue to write a new legend.