As a medium-carbon structural steel, 1045 steel is widely used in machinery manufacturing, automobile industry, construction and other fields due to its balanced performance and cost advantages. This article will quickly analyze the core characteristics of this classic material from three dimensions: composition, performance and application scenarios.

1. Chemical Composition of 1045 Steel: Simple But Crucial

1045 steel is a medium carbon steel (C: 0.43%~0.50%), and its naming rule directly reflects the carbon content (“45” represents an average carbon content of about 0.45%). The following is its typical chemical composition table:

| Grade | C | Si | Mn | P | S |

| 1045 | 0.43-0.50 | 0.15-0.35 | 0.60-0.90 | ≤0.04 | ≤0.05 |

Composition characteristics and influence:

- Carbon (C): core element, determines the hardness and strength of the material, but too high carbon content will reduce toughness and weldability.

- Manganese (Mn): improves hardenability, refines grains, and improves hot working performance.

- Impurity control: low phosphorus and sulfur content reduces the risk of cold brittleness and hot brittleness.

2. Analysis of the Core Performance of 1045 Steel: Why is It So Enduring?

2.1Mechanical properties (taking hot-rolled state as an example)

| Performance | Typical value | Improvement space after heat treatment |

| Tensile strength (Rm) | 570-700 MPa | Quenching + tempering can reach 850 MPa+ |

| Yield strength (Re) | 310-450 MPa | Quenching + tempering can reach 500 MPa+ |

| Elongation (A) | ≥16% | Proper tempering can maintain ≥12% |

| Hardness (HB) | 170-210 (unheated) | After quenching, it can reach 50-55 HRC |

Advantages:

- Strength and toughness balance: a typical feature of medium carbon steel, suitable for medium loads and impacts.

- Processing friendliness: cutting, forging, and welding performance are better than high carbon steel (such as 1060 steel).

Disadvantages:

- Poor corrosion resistance: surface treatment (such as galvanizing, painting) is required to prevent rust.

- Limited high temperature performance: long-term use temperature is recommended to be below 400℃.

2.2 Physical properties

- Density: 7.85 g/cm³ (similar to most carbon steels)

- Thermal conductivity: 50-60 W/(m·K) (suitable for heat dissipation scenarios)

- Conductivity: resistivity of about 0.15 μΩ·m (general conductivity, preferred for non-electrical materials)

3. Typical Application Scenarios: From Gears to Bolts

1045 steel is active in the following fields due to its high cost-effectiveness and process adaptability:

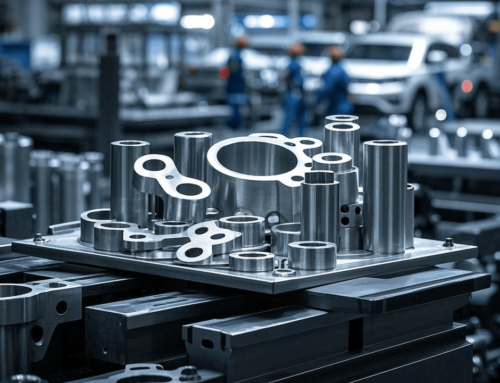

3.1. Automobile manufacturing

- Transmission parts: gears, camshafts, connecting rods (need to be heat treated and strengthened).

- Structural parts: bolts, brackets, flanges (cost-sensitive parts).

3.2. General machinery

- Shaft parts: medium-speed transmission shafts and spindles.

- Molds and tools: simple stamping dies, fixtures (surface hardening treatment is required).

3.3. Construction and engineering

- High-strength fasteners: 8.8-grade bolts and anchor bolts.

- Engineering structural parts: crane hooks, gearbox housings (need to be stress-relieved and annealed after welding).

4. Quick Answers to Common Questions About Material Selection

Q1: What is the difference between 1045 steel and Q235 steel?

A1:

- Composition: Q235 is a low-carbon steel (C≤0.22%) with low strength but better plasticity and weldability.

- Use: Q235 is suitable for building structures, and 1045 steel is suitable for mechanical load-bearing parts.

Q2: Do all 1045 steel parts need heat treatment?

A2: It depends on the working conditions! Light-loaded parts can be directly used in hot-rolled state, and high-load scenes recommend tempering treatment (quenching + high-temperature tempering).

Q3: What should be paid attention to during welding for 1045 steel?

A3: Preheat to 150-250℃ (anti-crack), slow cooling or stress relief annealing after welding.

Q4: Can 1045 steel be used to replace higher-end materials (such as 5140)?

A4: It is feasible in non-heavy-load and non-high-fatigue scenes, but the strength and life need to be re-checked.

5. Summary: The “Applicability Philosophy” of 1045 Steel

- Advantage areas: medium strength, low cost, easy processing scenarios.

- Cautionary use scenarios: high corrosion environment, ultra-high frequency fatigue load, extreme low temperature/high temperature conditions.

Through reasonable heat treatment and surface modification, 1045 steel can continue to be revitalized in modern industry. For engineers, mastering its performance boundaries is the key to realizing the value of materials!