DIN 1.2601/X165CrMoV12 steel is defined as cold work tool steel as per DIN 17350 standard.As a high carbon and high chromium alloy tool steel, DIN 1.2601 steel has excellent wear resistance, fatigue resistance, impact resistance, as well as good strength and toughness. It is usually delivered in the annealed condition.

The application of DIN 1.2601 steel is similar to that of DIN 1.2379 steel. it is usually used for dimensionally stable high performance cutting steel, fracture sensitive cutting dies, metal saws, press trimmers, bending dies,guillotine blades for a sheet thickness up to 6 mm, cold shearing blades, flash trimming dies, thread rolling tools, highly stressed woodworking tools, hobbing tools, extruding tools.

DIN 1.2601/X165CrMoV12 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | V | W |

| 1.2601 | 1.55-1.75 | 0.25-0.4 | 0.2-0.4 | ≤ 0.03 | ≤ 0.03 | 11.0-12.0 | 0.5-0.7 | 0.1-0.5 | 0.4-0.6 |

DIN 1.2601/X165CrMoV12 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA:Cr12MoV

USA:D2

JAPAN:SKD11

Italy:X165CrM0W12KU

DIN 1.2601/X165CrMoV12 STEEL FORGING

- Initial Forging Temperature:1000-1060℃

- Final Forging Temperature: 850-900℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high carbon high alloy tool steel,DIN 1.2601 steel should be annealed after forging.

DIN 1.2601/X165CrMoV12 STEEL HEAT TREATMENT

- DIN 1.2601 Steel Complete Annealing

The general annealing temperature of DIN 1.2601 steel is 850-870℃,and the holding time is 3-6 hours,and then furnace cooled to 500-600℃ with the rate 30℃/h max.Annealed hardness is usually below 255HBW.

- DIN 1.2601 Steel Isothermal Spheroidizing Annealing

The isothermal spheroidizing annealing temperature of DIN 1.2601 steel is 850-870 ℃, which is kept for 2-4 hours and then cooled to 720-740 ℃ with the furnace, and kept for 3-4 hours.Finally cooling to below 500-600°C with the rate 30℃/h max in the furnace and then air-cooling.Annealed hardness is usually below 255HBW.

- DIN 1.2601 Steel Quenching & Tempering

Quenching Temperature:980-1010℃

Quenching Medium:oil/air/hot bath

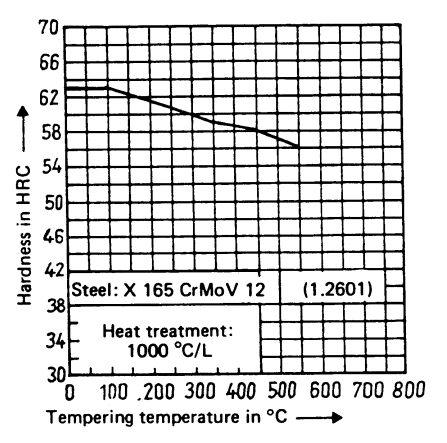

Tempering Temperature:160-180℃ Followed by Quenching

Hardness: Min 60HRC

Structure:Fine granular pearlite + carbide

DIN 1.2601 Steel Tempering vs Hardness Diagram

DIN 1.2601/X165CrMoV12 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |