DIN 1.2379/X155CrVMo12-1 steel is defined as high carbon and high chromium tool steel as per DIN 17350 standard.

As the representative steel of cold working die steel,DIN 1.2379 steel has high hardness,good wear resistance,dimensional stability,toughness and hardenability after heat treatment.

Din 1.2379 steel is suitable for making cold working dies with high precision, long life and high wear resistance, such as precision stamping dies, cold extrusion forming dies, deep drawing dies, blanking dies, embossing dies and cold forging dies.

DIN 1.2379/X155CrVMo12-1 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

DIN 1.2379/X155CrVMo12-1 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | V | Mo |

| 1.2379 | 1.5-1.6 | 0.1-0.4 | 0.15-0.45 | ≤ 0.03 | ≤ 0.03 | 11.0-12.0 | 0.9-1.1 | 0.6-0.8 |

DIN 1.2379/X155CrVMo12-1 STEEL RELATED STANDARD & EQUIVALENT GRADE

China:Cr12MoV

USA:D2

Japan:SKD11

DIN 1.2379 STEEL FORGING

- Initial Forging Temperature:1010-1200℃

- Final Forging Temperature:above 927℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high carbon cold work tool steel ,DIN 1.2379 steel should be annealed after forging.

DIN 1.2379 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of DIN 1.2379 Steel

- Ac1:830℃

- Ac3:855℃

- Ar1:750℃

- Ms:230℃

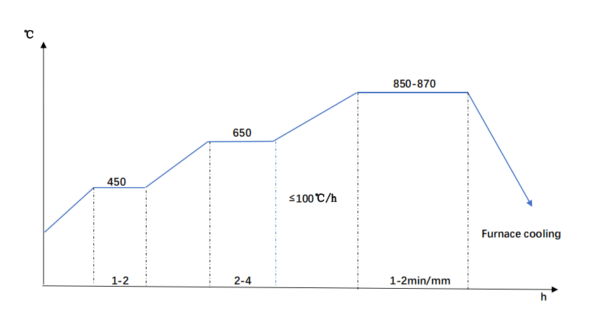

DIN 1.2379 steel Annealing

The general conventional annealing temperature of DIN 1.2379 steel is 850-870℃,and the holding time is determined by 1h per 25mm wall thickness,then furnace cooled to 500℃ with the rate 22℃/h max.Annealed hardness is usually below 255HBW.

DIN 1.2379 Steel Annealing Diagram

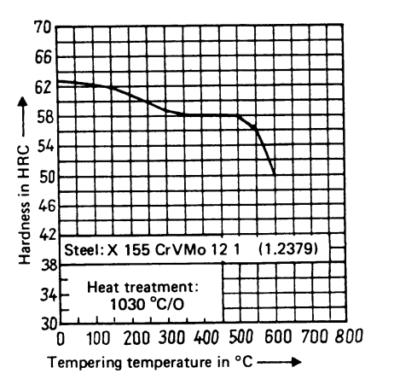

DIN 1.2379 steel Quenching & Tempering

Pre-heat Temperature:840-860℃

Quenching Temperature:1020-1050℃

Quenching Medium:oil,hot bath,air

Tempering Temperature:150-200℃ Followed by Quenching

Hardness: Min 60HRC

DIN 1.2379 Steel Tempering vs Hardness Diagram

Forged cylinder D2 tool steel