DIN 1.2080 steel contains 2.1% carbon and more than 11% chromium alloy, which is defined as high carbon and high chromium cold work tool steel as per DIN 17350 standard.

As one of the classic representative steels of cold work tool steel, DIN 1.2080 steel has the characteristics of high strength, high toughness, high hardness, high hardenability, excellent wear resistance and good processing performance.

DIN 1.2080/X210Cr12 steel is usually delivered in annealed condition with hardness below 248HBW.

DIN 1.2080/X210Cr12 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr |

| 1.2080 | 1.9-2.2 | 0.1-0.4 | 0.15-0.45 | ≤0.03 | ≤0.03 | 11.0-12.0 |

DIN 1.2080/X210Cr12 STEEL RELATED STANDARD & EQUIVALENT GRADE

China:Cr12

USA:D3

Japan:SKD1

DIN 1.2080/X210Cr12 STEEL FORGING

- Initial Forging Temperature:1080-1100℃

- Final Forging Temperature:880-920℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high carbon-chromium cold work tool steel ,DIN 1.2080 steel should be annealed after forging.

DIN 1.2080/X210Cr12 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of DIN 1.2080 Steel

- Ac1:810℃

- Ac3:835℃

- Ar1:755℃

- Ms:180℃

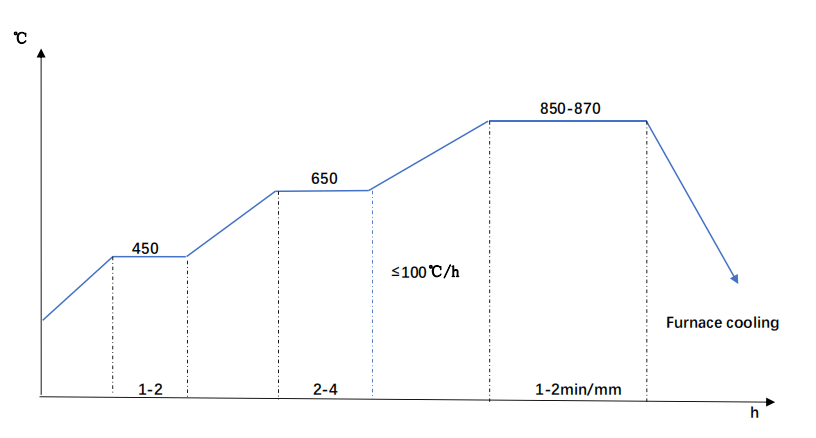

DIN 1.2080 steel Annealing

The general annealing temperature of DIN 1.2080 steel is 850-870℃,and the holding time is 3-6 hours,and then furnace cooled to 500-600℃ with the rate 30℃/h max.Annealed hardness is usually below 248HBW.

DIN 1.2080 Steel Annealing Diagram

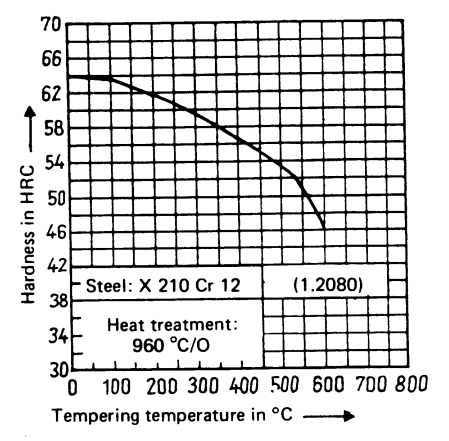

DIN 1.2080 steel Quenching & Tempering

Pre-heat Temperature:800-850℃

Quenching Temperature:950-980℃

Quenching Medium:oil

Tempering Temperature:180-200℃ Followed by Quenching

Hardness: 60-62HRC

DIN 1.2080 Steel Tempering vs Hardness Diagram

DIN 1.2080/X210Cr12 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

DIN 1.2080/X210Cr12 STEEL APPLICATIONS

Cutting tools, guillotine blades for cutting steel sheet up to about 3 mm thick and for cutting hardened steel strip, broaches, highly stressed woodworking tools where the toughness requirement is not too high, shaping and flanging tools, blades for producing chopped wire, thread rolling tools, deep drawing tools, press tools for the ceramic and pharmaceutical industry,drawing cones for wire drawing, extruding tools and guide strips, sand blasting nozzles.