4120 steel is a low carbon alloy structural steel containing Cr-Mo alloying elements as per American standard ASTM A29.

As a Cr-Ni series low alloy steel,4120 steel has high hardenability without temper brittleness.It performs well in machinability and cold strain plasticity.Due to the low carbon content, the weldability of 4120 steel is quite good, and the tendency to form cold cracks is small.

4120 steel is generally used in the condition of quenching and tempering or carburizing and quenching.It is often used in the manufacture of high-pressure pipes and various fasteners, higher-grade carburized parts, such as gears, shafts, etc.

4120 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4120 | 0.18-0.23 | 0.15-0.35 | 0.9-1.2 | ≤0.035 | ≤0.04 | 0.4-0.6 | 0.13-0.20 |

4120 STEEL RELATED STANDARD & EQUIVALENT GRADE

China | GB 3077:20CrMoA

Japan | JIS G4105:SCM420

4120 STEEL FORGING

- Initial Forging Temperature:1200℃

- Final Forging Temperature:800℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:4120 steel should be slowly cooling in sand after forged.

4120 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 4120 Steel

- Ac1:743℃

- Ac3:818℃

- Ar1:504℃

- Ar3:746℃

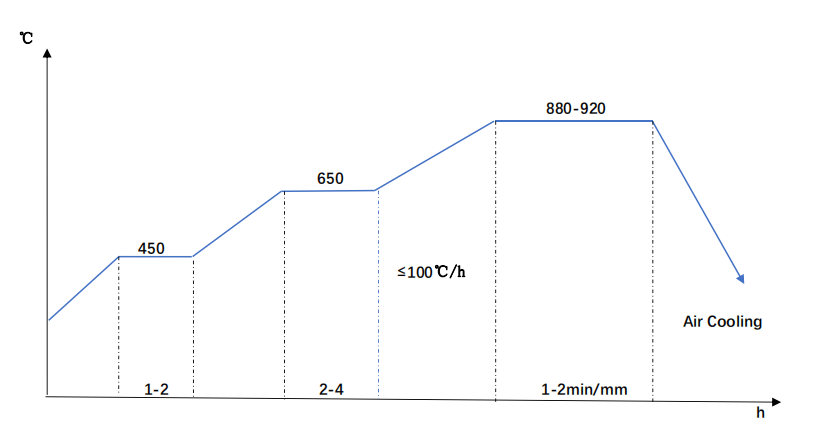

4120 Steel Normalizing

- Heating temperature:880-920℃

- Heat holding time:The holding time of normalizing heating is based on the principle of sufficient heating.Calculated according to the effective section size of the material, generally 1 minute/mm.

- Cooling:Air cooling

4120 Steel Normalizing Diagram

4120 Steel Quenching & Tempering(Q&T)

Process Details

- Quenching Temperature:870-890ºC

- Quenching Medium: Oil/Water

- TemperingTemperature:500ºC

- Cooling Medium:Oil/Water

4120 Steel Mechanical Property with Quenched and Tempered Condition

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| ≥800 | ≥600 | ≥12 | ≥50 | ≥90 |

| Remark: Quenching at 880ºC,Tempering at 500ºC | ||||

4120 Steel Carburization

- Carburizing Temperature:920-940ºC

- Quenching Temperature:810-830ºC

- Quenching Medium: Oil/Water

- TemperingTemperature:160-200ºC

- Hardness:58-64HRC

4120 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

AISI 4120 Forged Round Steel